- Product Details

- {{item.text}}

Quick Details

-

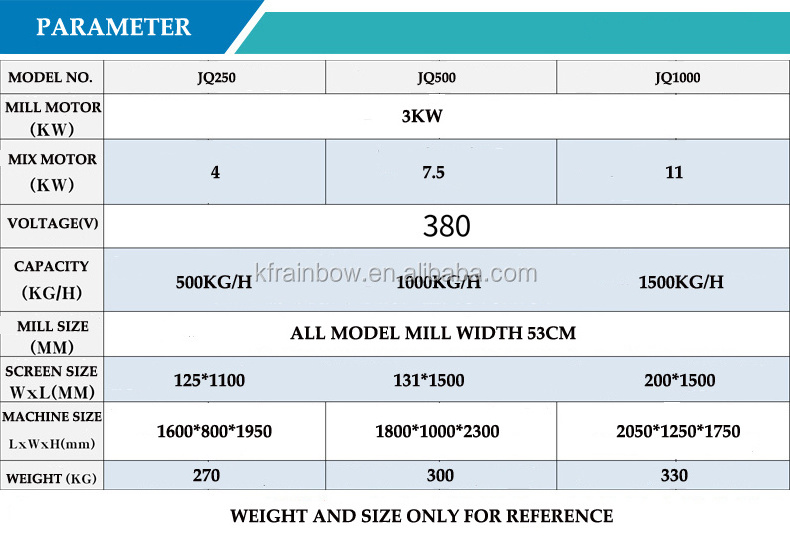

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

160*85*195Cm

-

Weight:

-

300 kg

-

Warranty:

-

One Year

-

Application:

-

Poultry Farm

-

Capacity:

-

750-1000kg/h

-

Raw material:

-

Soybean meal, grain, other

-

Advantage:

-

High Capacity

-

Color:

-

Green

-

Crushing principle:

-

self-priming hammer mill

-

Mixing principle:

-

Vertical spiral upgrade

-

For animal type:

-

Poultry, livestock classes, other

-

Usage:

-

Animal Poultry Livestock Pellet Making Machine

-

Material:

-

Stainless

Quick Details

-

Max. Capacity:

-

1ton/h

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

RB

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

160*85*195Cm

-

Weight:

-

300 kg

-

Warranty:

-

One Year

-

Application:

-

Poultry Farm

-

Capacity:

-

750-1000kg/h

-

Raw material:

-

Soybean meal, grain, other

-

Advantage:

-

High Capacity

-

Color:

-

Green

-

Crushing principle:

-

self-priming hammer mill

-

Mixing principle:

-

Vertical spiral upgrade

-

For animal type:

-

Poultry, livestock classes, other

-

Usage:

-

Animal Poultry Livestock Pellet Making Machine

-

Material:

-

Stainless

KAIFENG RAINBOW MACHINERY CO.,LTD

Pig/ sheep/ chicken/ cow/poultry feed mill plant/ Poultry Feed grinder and Mixer/ Feed crushing Machine

Animal feedstuff making machine. The vertical crushing mixer, which takes small area ,is suitable for producing all-around.this machine can grind and mix feedstuff at same time, saving energy, and high efficiency .

This ma chine can be used to crush all kinds of cereal, grain, like corn, wheat, bean, and others to powder that can make animal feed or for other process, it has the crush and mix function at the same time, very convenient and easy to operate

Animal feeder & mixer usually is matched using for the pellet machine for the animal feed processing. Feed crusher & mixer is sold quite well all over the European countries.

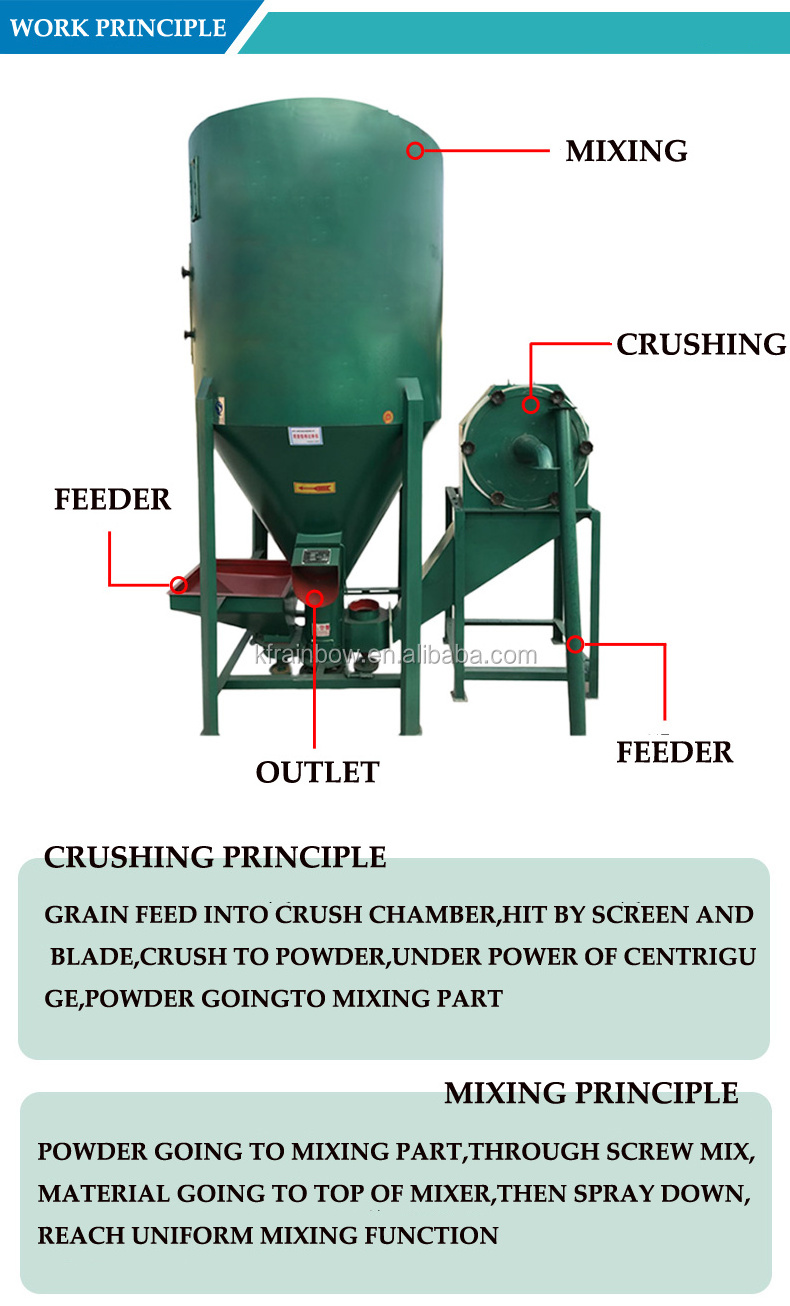

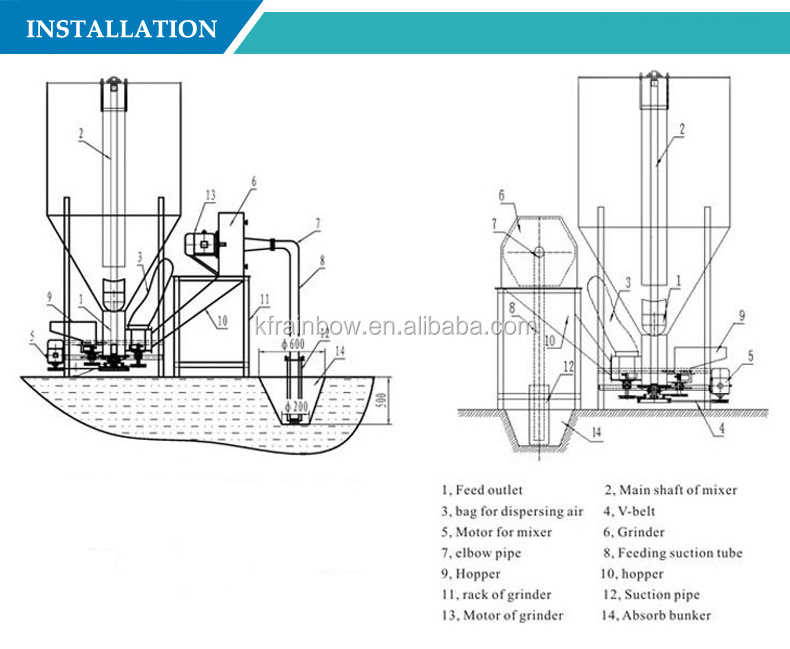

Principle of work of the animal feed crusher &mixer :

This machine can be divided into two parts, a crushing structure and a material structure.

1.The crushing structure: There are two ways to input the materials: automatically or manually. When the raw materials were put into the crushing room, with the beating of the hammer leaf and the scrubbing of the air, the raw materials will be crushed into mealiness or graininess. Then under the effect of the centrifugal air, the mealiness or the graininess will get in to the A impeller casing through the sieve pore.

2.The materials mixing structure: with the whirling of the thruster, the materials will be transferred into the material pipeline by the B hammer room by force. There, the materials will be lifted to the top of the room and be totally mixed up and down and spined from left to right via the air. Therefore, the materials can be evenly mixed which is quite ideal.

About packaging, for small size or single machine, we can offer free fumigation wooden case with steel frame, it not only can protect machine from damage, but also avoid checking when exporting.

For multiple machines or production line, it's better to loaded in standard container 20GP, 40GP, 40HQ, unually it needs wrapped with plasitc firstly, then loaded in container.

we can offer EXW, FOB and CIF terms.

EXW: You arrange the shipping details from our factory to your port by yourself.

FOB: We arrange freight transport to Qingdao, Shanghai or other ports of China, then you arrange the shipping details from China port to your country port.

CIF: We arrange all shipping details to your country port, and ensure machines smooth arrival.

1. Help you choose the most suitable machine.

2. Making the machine according to your request.

3. Give you machine’s details and video for help you use the machine more better.

4. One year warranty

5. Quality problem,we will send you the accessories.

6. Free repair whole using life without extra charge.