- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

95 KG

-

Dimension(L*W*H):

-

810x440x670

-

Product name:

-

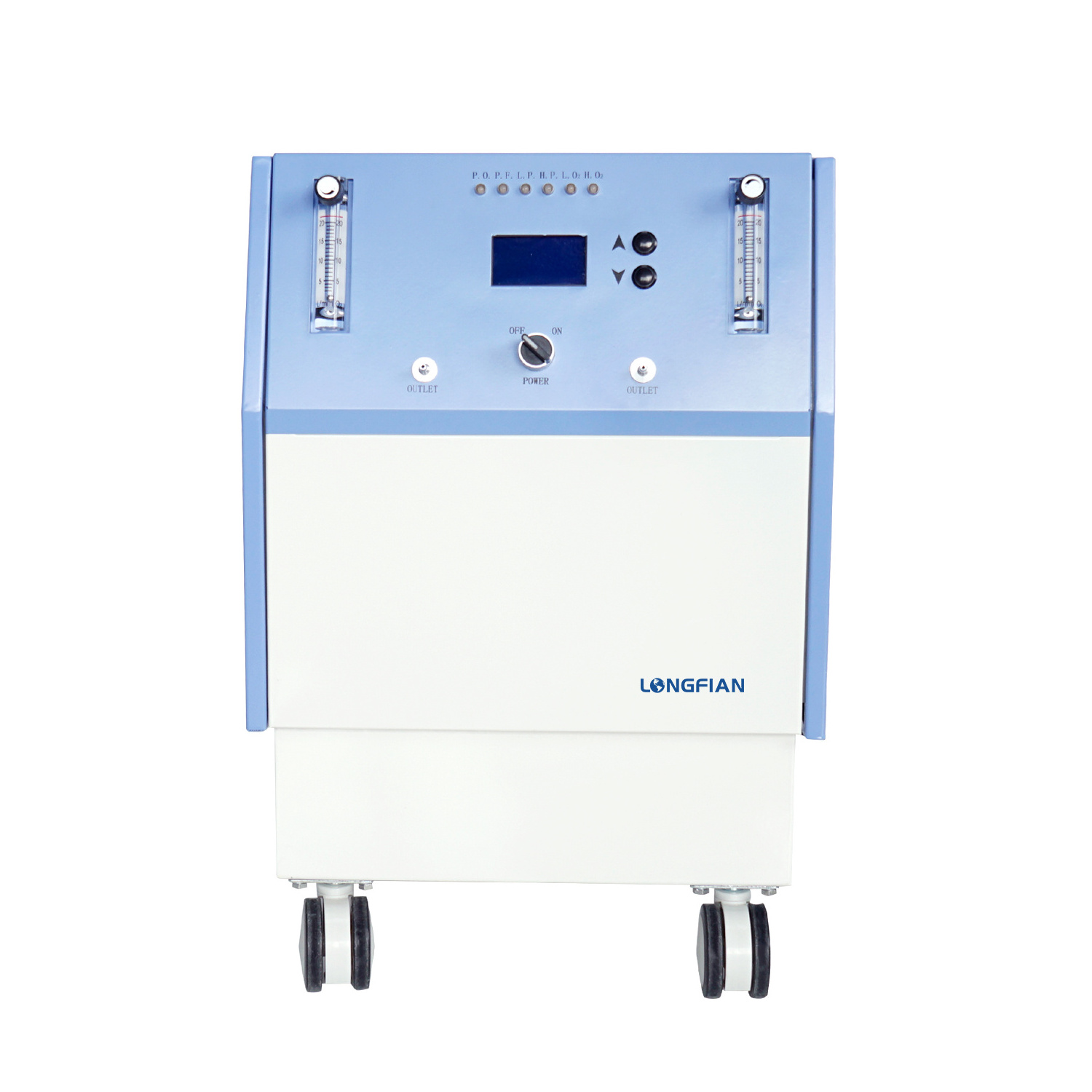

Industry Oxygen Concentrator

-

Material:

-

Iron

-

Size:

-

810*440*670mm

-

Application:

-

glass cutting and blowing

-

Color:

-

Blue and White

-

Oxygen concentration:

-

93% ±3%

-

Outlet pressure:

-

0.04-0.07Mpa

-

Certificate:

-

ISO

-

HS code:

-

8421399090

Quick Details

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

Longfian

-

Voltage:

-

110/220v

-

Weight:

-

95 KG

-

Dimension(L*W*H):

-

810x440x670

-

Product name:

-

Industry Oxygen Concentrator

-

Material:

-

Iron

-

Size:

-

810*440*670mm

-

Application:

-

glass cutting and blowing

-

Color:

-

Blue and White

-

Oxygen concentration:

-

93% ±3%

-

Outlet pressure:

-

0.04-0.07Mpa

-

Certificate:

-

ISO

-

HS code:

-

8421399090

Product Description

Oxygen Generators for Glass Cutting

Oxygen is the most commonly used assist gas for mild-steel cutting applications. Oxygen causes an exothermic reaction that helps provide the heat to make laser cutting possible. First, oxygen requires a much lower flow and pressure than nitrogen, meaning the consumption—and ultimately the costs—are lower. Also, at thicknesses of more than .08 inches, oxygen cuts faster.

Why Glassblowers Rely on Oxygen Generators

Instead of having to manage and maintain oxygen cylinders, many artists are choosing to implement the use of an on site oxygen generator. This is for many reasons:

It Is Dependable – Not all glassblowers work in urban areas, and getting cylinders delivered is not reliable. With on site oxygen generation, there is no risk of running out of gas, so operations won’t have to come to a halt.

It Is Affordable – Oxygen cylinders can get expensive, and they are a recurring cost that doesn’t go away. On the contrary, with on site oxygen generation, glassblowers only have the upfront costs to worry about. Once those have been recouped, the artist can continue producing oxygen for essentially no additional costs.

Is It Safe – The art of glassblowing is dangerous enough, the last thing a glassblower needs to worry about is a high-pressure cylinder exploding and damaging something in the shop.

It Is Durable – Our on site oxygen generators are made to handle the most rugged environments, so wherever the glassblowing is being performed, the oxygen generator will stand the test of time.

|

Flow Rate

|

1-20LPM

|

|

Purity

|

93%(±3%)

|

|

Outlet Pressure

|

0.04-0.07MPA

|

|

Sound Level

|

≤55db

|

|

Power Consumption

|

1100w

|

|

LCD Display

|

Switch times, operating pressure, present working time,accumulated working time

|

|

Net Weight

|

95Kgs

|

|

Power

|

AC220V±10%,50/60HZ; AC110V±10%,50/60HZ

|

|

Alarm

|

High&low pressure alarm,Power failure alarm

|

|

Size

|

810*440*670mm

|

Details Images

The Role of Oxygen Generators in Glass Blowing and Cutting

Glassblowing is a unique art that combines the skill of melting glass with the subtle blowing of air to form masterful decorations. However, in order to work properly, the flame that the glassblower uses must be a specific temperature. That’s where oxygen gas comes in. With the high purity of oxygen gas provided by our 93% O2 PSA oxygen generators, glassblowers can make sure their torches remain the proper temperature for their masterpiece.

How They Use It

As mentioned, glassblowers rely on oxygen as their fuel for the burners and torches they use to melt the glass. Basic compressed air just doesn’t produce the necessary heat. Oxygen is the only fuel source that will ensure the flame is hot enough to effectively and strategically melt quartz and borosilicate glass. In most situations, the glassblower will use oxygen gas at a range of 10-15 psi, with a purity of 93%.

Packaging and Shipping

Our Company

We are Longfian

Longfian Scitech Co., Ltd, a leading manufacturer specialized in oxygen solutions for 25 years, has been professionally dedicated to R&D, production and marketing of various oxygen concentrators which include medical oxygen therapy, indoor oxygen supply, plateau simulation, industrial, veterinary and other fields. Longfian is headquartered in Baoding, China. We have 520 employees, covering an area of 40,000 square meters, with annual production capacity of 1.5 million units.

2 Million Praises from Worldwide

All of our products comply with ISO13485 quality managing system and some models obtained CE certificates. in the meantime, our technology and R&D team carried out technological innovations, awarded 28 invention and design patents, and completed registration of 36 countries for import permits. till now, Longfian, has got the market share over 70% and exported to more than 160 countries around the world, benefiting 2 million end-users.

WHO & the United Nations Awards and Recognition

Longfian is the designated qualified supplier of United Nations organizations. Presently, we have undertaken many rescue material projects of oxygen concentrator from all over the world. Last year, we supplied nearly 1,200,000 units oxygen concentrators to different countries and they have expressed their recognition and gratitude to Longfian.

Mission

On base of having realized the basic oxygen supply field, we will focus on intelligent, community-based and customized oxygen development. Longfian adheres to the value of “superior quality, professional technology, devotion to oxygen solution” and strives to care for human respiration, empowers oxygen to every rhythm of life.

Longfian Footprint in the World

Since the year 1998, we started to go deep and explore the world market. 25 years export experience, 95 countries visits(like USA, Mexico, Colombia, Brazil, United Kingdom,Germany, Romania,Spain, Russia, Tajikistan, India,Thailand, Vietnam, South Africa, Nigeria etc.), more than 480 international exhibitions (including the FIME, MEDICA, ARAB HEALTH, HOSPITALAR, CMEF etc. ) which all laid a solid foundation for the No. 1 export volume of China-Made Oxygen Concentrator for recent 6 consecutive years and make LONGFIAN brand the benchmark of the mark.

FAQ

Q: Are you a factory or trading company? A:We are a leading manufacturer specialized in oxygen solutions for 25 years. We have 520 employees, covering an area of 40,000 square meters, with annual production capacity 1.5million units. Welcome to visit us! Seeing is believing, our office, showroom and workshop are in the same place. Q. Where is your factory located? How can I visit there? A: Our factory is located at Power valley pioneer park, NO.369 Huiyang street , 071051,Baoding, Hebei,China, near to Beijing, It only takes half an hour from Beijing to our factory by train. We also can provide pick-up service if needed. Q. What is your payment and trading term? A: 1. Payment term: T/T, or L/C , or Visa, MasterCard, PAYPAL, APPLE_PAY, GOOGLE_PAY. 2. Trading term: EXW/FOB/CIF etc.

Q: How to purchase your product?

A: Quotation → PI → PI confirmation → Payment receiving →Producing →QC inspection→ Packing → Shipping

Q: Which port do you choose?

A: Tianjin, Beijing, Shenzhen Sea Port or Air Port, or chosen by you.

Q:Can I print our logo on the products and change the color of products?

A: Yes, we provide OEM services. Please tell us your requirement, we will do customized products for you.

Hot Searches