- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

15000 kg

-

function:

-

deal with waste black oil

-

Water content:

-

0.05%W/W

-

Carbon residue:

-

0.13%W/W

-

Flash point open:

-

180--210

-

Pour point:

-

-15--10

-

Certification:

-

CE

Quick Details

-

Flow:

-

3-30 ton/day

-

Place of Origin:

-

Chongqing, China

-

Brand Name:

-

JUNNENG

-

Weight:

-

15000 kg

-

function:

-

deal with waste black oil

-

Water content:

-

0.05%W/W

-

Carbon residue:

-

0.13%W/W

-

Flash point open:

-

180--210

-

Pour point:

-

-15--10

-

Certification:

-

CE

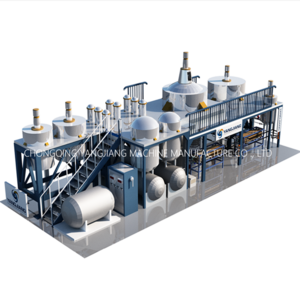

used motor oil distillation processors for sale

Product details

| function | deal with waste black oil |

| Water content | ≤0.05%W/W |

| Carbon residue | ≤0.13%W/W |

| Flash point open | ≥180--210℃ |

| Pour point | -15--10℃ |

| Appearance | Transparency |

| Acidity | ≤0.05mgKOH/g |

| Product Keywords | used motor oil distillation processors for sale |

Features:

ZSA series waste oil recycling machine

overview : This machine can treat a variety of waste lube oil, to get high quality base oil and a small amount of gasoline and diesel through vacuum distillation. After pretreatment, waste oil pumping into the distillation kettle, and heating to working temperature, we will can get the base oil, gasoline and diesel .When reaction completed, stop heating, remove residue from the bottom of the tank, then the machine can be used again. The production is economical, however, the base oil is excellent .This is the most advanced technology in the world in the waste oil recycling field, and it is suitable for large-scale industrial production.

Systems of equipment

1 Pretreatment system : Waste oil will be pumped into the distillation kettle after pretreated.

2 Distillation system: through burning coal,gasor fuel oil to make the oil in the kettle up to the working temperature. This system equipped with stirring system and insulation system.

3 Cooling system: the gaseous hydrocarbon will be cooled into liquid base oil. Gasoline and diesel.

4 Oil storage system: the base oil, gasoline and diesel get from cooling system storage here, and then pump into the storage tank.

5 Vacuum system: meet the technology requirement.

6 Filtration system: rapidly filter out mechanical impurities in the base oil, gasoline and diesel, get the high quality base oil, gasoline and diesel.

Recovery rate

Base oil: 85%~88 %( index same as SN150~SN200)

Gasoline: about 3%

Diesel: about 3%-4%

Oil residue: 6%~8%

Index of oil after treatment

|

No |

Item |

Unit |

Technical data |

|

|

Light base oil |

Medium/heavy base oil |

|||

|

1 |

Viscosity(40 ℃ ) |

mm2/s |

16~32 |

28~72 |

|

2 |

Viscosity index |

|

≥99 |

110 |

|

3 |

Appearance |

|

Transparency |

Transparency |

|

4 |

Color index |

ASTMD1500 |

≤1.2 |

≤1.6 |

|

5 |

Pour point |

℃ |

-15 |

-10 |

|

6 |

Water content |

%W/W |

≤0.05 |

≤0.05 |

|

7 |

Flash point open |

℃ |

≥180 |

≥210 |

|

8 |

Ash content |

%W/W |

0.005 |

0.005 |

|

9 |

Carbon residue |

%W/W |

≤0.13 |

≤0.13 |

|

10 |

Corrosioncopper,100 ℃ 3h |

Qualified |

Qualified |

|

|

11 |

Acidity |

mgKOH/g |

≤0.05 |

≤0.05 |

performance characteristics , advantage introduction

1 widely usage: can treat gasoline engine oil, diesel engine oil, rubber oil, waste oils and other various cleaning oil

2 low processing costs: the total cost of processing one ton used oil only USD30(including fuel, electricity and pretreatment agent)

3 high recovery rate: base oil:85%~88%,gasoline 3%,diesel:3%~4%,oil residue:6%~8%

Current the continuous operation practices in the market, while the good oil come out, at the same time pump waste oil in. This operation is complicated,labor-intensive,and a lot of good oil will be pumped as residue oil , the yield at most up to 72% ,too much residue oil.

4 Do not need acid and clay, get high quality base oil : No unsaturated composition, can storage in a long-term without change its color, also no any bad smell.

5 environmental protection: the whole process is all sealed, won’t release any gas harmful to human and environment, the colloid and asphalting, carbon black in the waste lube oil are all into sludge, can be used as asphalt or fuel.

6 this machine use a special way heating, high thermal efficiency, and difficult to form carbon fouling.safe,reliable,durable.this is the most advanced technology in the world and suitable for large-scale industrial production.

7 easy operation, low labor intensity, only 1 to 2 workers can easily operate the machine.

Quality assurance:

1, product quality assurance for one year, any non-artificial damage, shall be the responsibility of the manufacturer.

2, the manufacturers provide overseas engineers, door-to-door guidance, installation and use.