- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

GFG

-

Model Number:

-

LAMINATED

-

Tempering Method:

-

Physical wind tempering

-

Float glass thickness:

-

3-19mm float glass

-

Max Glass Size:

-

2440mm*5000mm

-

Tempering Equipment:

-

Glaston furnace (Finland)

-

6mm force after tempered:

-

100KG

-

Temperature change range:

-

75℃

-

bending force:

-

≥70MPa

-

Laminating equipment:

-

China Handong

-

High pressure furnace:

-

Fuer

Quick Details

-

Application:

-

Courtyard, Supermarket, Workshop, Kitchen, Bathroom, Living Room, Park, Office Building, Storage & Closet, Mall, Entry, Apartment, Basement, Hospital, Villa, Hotel, Hall

-

Usage:

-

Industrial, Balustrades & Handrails, Image formation

-

Thickness:

-

3mm-12mm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

GFG

-

Model Number:

-

LAMINATED

-

Tempering Method:

-

Physical wind tempering

-

Float glass thickness:

-

3-19mm float glass

-

Max Glass Size:

-

2440mm*5000mm

-

Tempering Equipment:

-

Glaston furnace (Finland)

-

6mm force after tempered:

-

100KG

-

Temperature change range:

-

75℃

-

bending force:

-

≥70MPa

-

Laminating equipment:

-

China Handong

-

High pressure furnace:

-

Fuer

1

The raw float glass from

XINYI

or

TG glass

, to guarantee the Paneness and clearness.

2

The glass was heat strengthened by our

Glaston

tempering line ( Imported from Finland)

3

The glass was heat strengthened by

s

killed workers

with around 6 years experience for tempering flat glass, the quality is stable.

4

Fast lead time:

10-15

days.

5

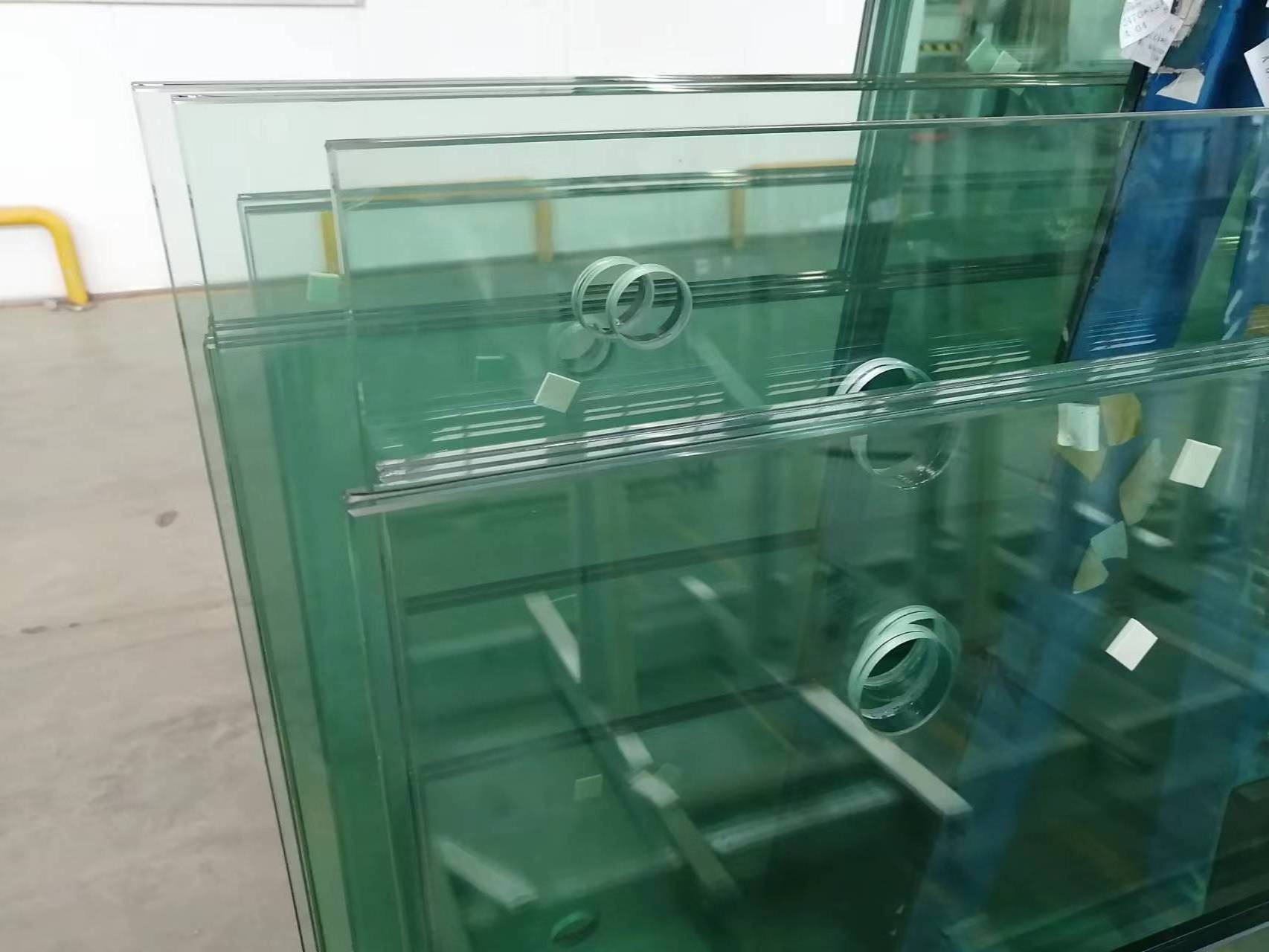

Equipped with

CNC working centre

to satisfy special shaped edg grinding and cut-out.

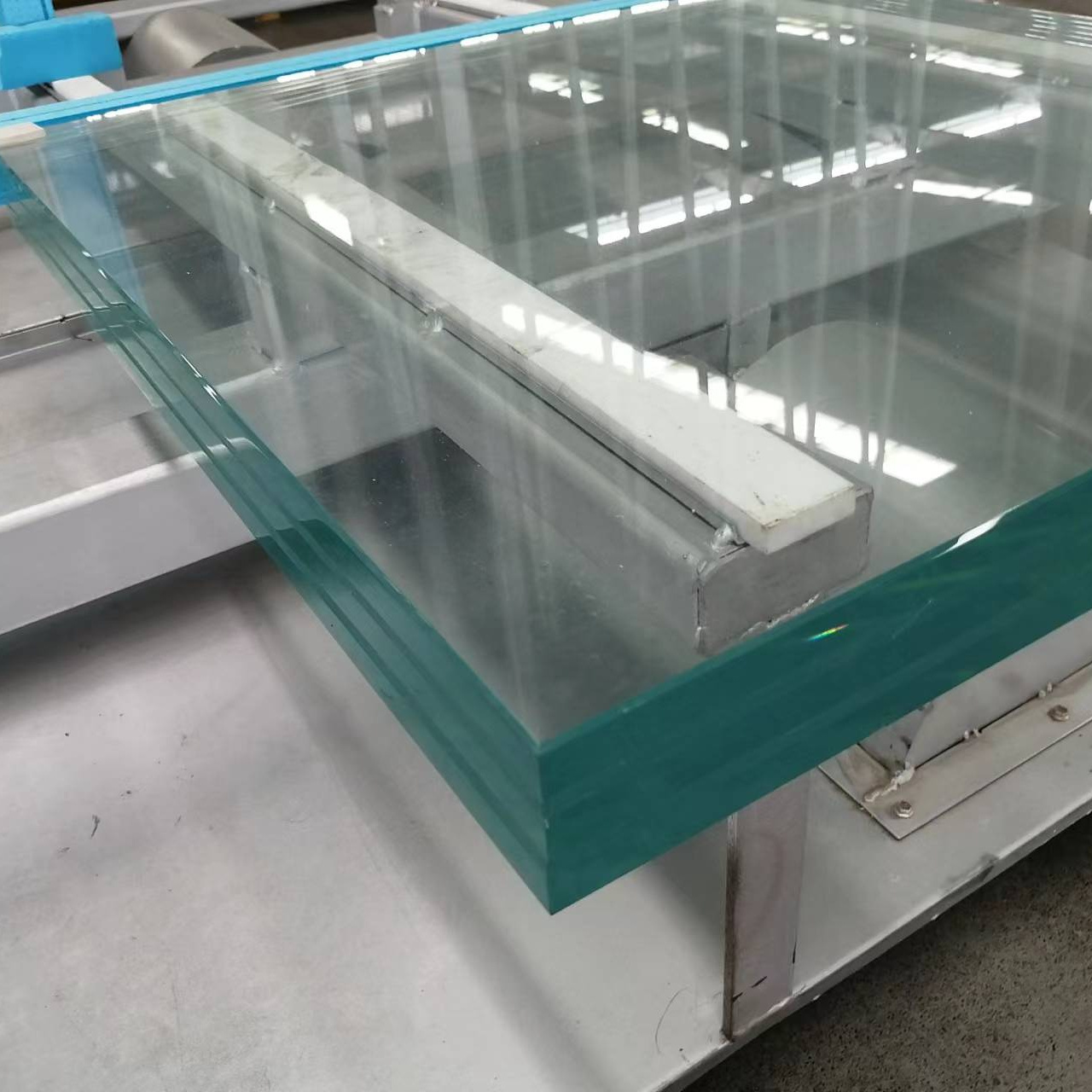

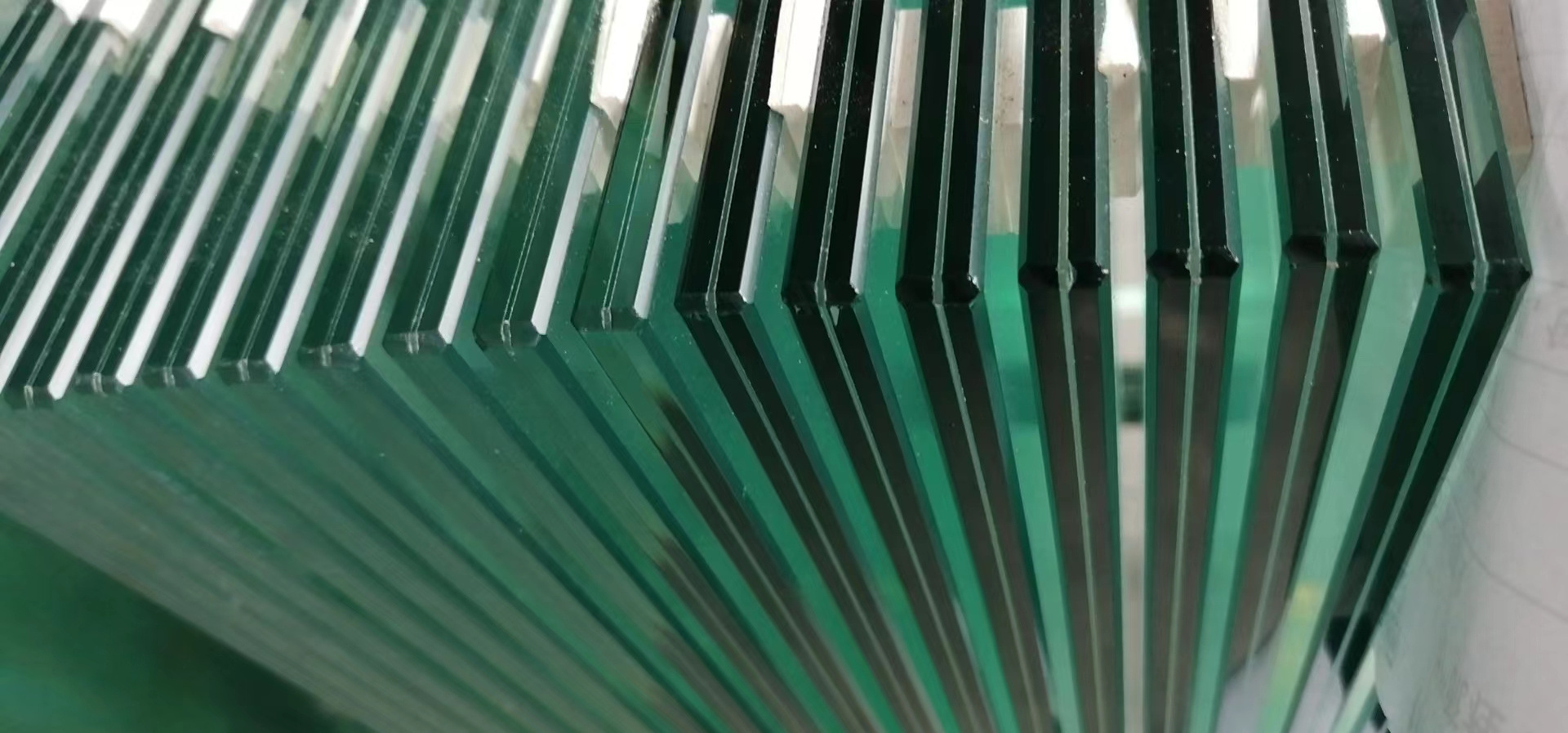

Laminated glass widely used for balustrade,handrail, office patition.

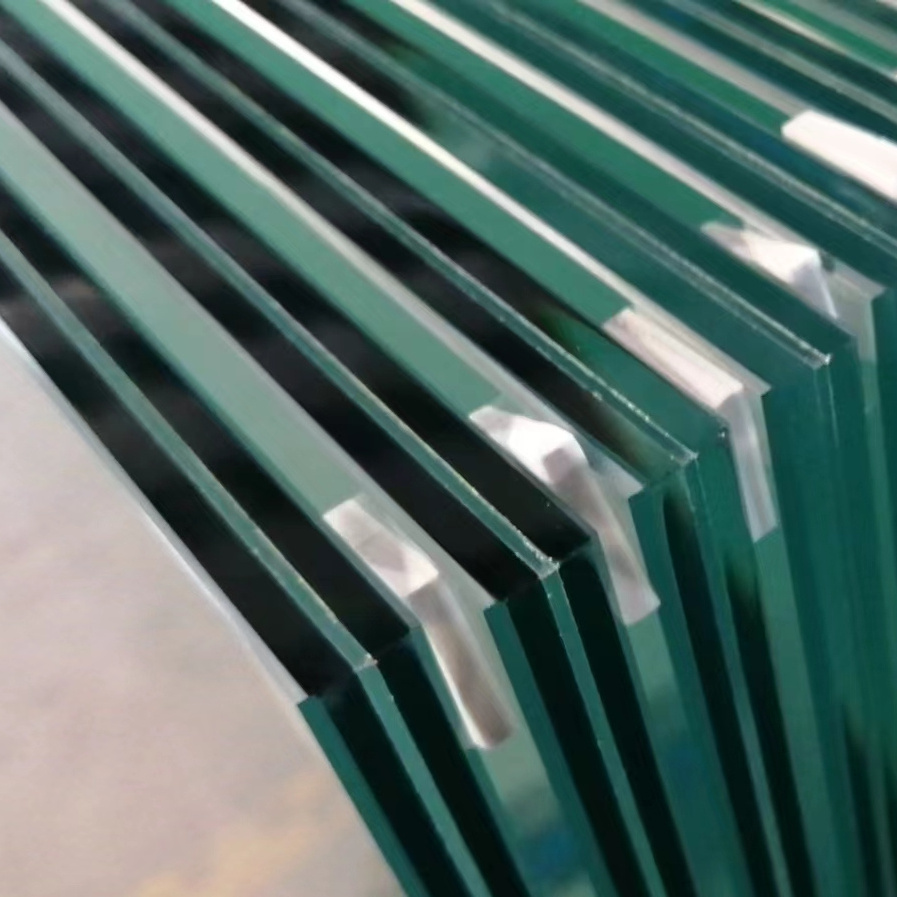

5+1.52PVB+5 , 6+1.52PVB+6, 5+1.14PVB+5, 6+1.52PVB+6.

8+1.52PVB/SGP+8, 10+1.52PVB/SGP+10

Our standard parking method:

Non-fumigation wooden crates+ plastic film + desiccant.

For Quality Standard, our company passed CE ( EN 14449:2005+AC:2005), and Australia Standard AS/NZS 2208:1996, and China Nation stardard for building glass.

Every batch products will be inspected by our QC team, visual inspection & performance test,

such as Dimensions,Physical Defect, D rop Ball Test, Impact Test, Waving Test,Pendulum Impact Test,

Surface Compression Test, Fragmentation Test.. ect, to guarantee every batch products' quality.