- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Huayin

-

Voltage:

-

380v/50hz

-

Power:

-

12-24KW

-

Dimension(L*W*H):

-

2800*6000mm

-

Weight:

-

30 Tons

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Online support

-

Function:

-

mini oil refinery plant

-

Name:

-

waste oil recycling machine

-

Raw material:

-

waste oil , engine oil , motor oil , car oil , crude oil

-

End product:

-

clean diesel oil with yellow color

-

Heating method:

-

Directly Heating

-

Thickness:

-

16/18mm

-

oil yield:

-

90%

-

Landing area:

-

300-400 square meter

-

warranty:

-

1 year

-

Certification:

-

CE ISO

Quick Details

-

Applicable Industries:

-

Waste Recycling

-

Flow:

-

Day

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Huayin

-

Voltage:

-

380v/50hz

-

Power:

-

12-24KW

-

Dimension(L*W*H):

-

2800*6000mm

-

Weight:

-

30 Tons

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Online support

-

Function:

-

mini oil refinery plant

-

Name:

-

waste oil recycling machine

-

Raw material:

-

waste oil , engine oil , motor oil , car oil , crude oil

-

End product:

-

clean diesel oil with yellow color

-

Heating method:

-

Directly Heating

-

Thickness:

-

16/18mm

-

oil yield:

-

90%

-

Landing area:

-

300-400 square meter

-

warranty:

-

1 year

-

Certification:

-

CE ISO

Xinxiang huayin mini oil refinery equipment for sale with good price

1. DESCRIPTION OF MINI OIL REFINERY EQUIPMENT FOR SALE

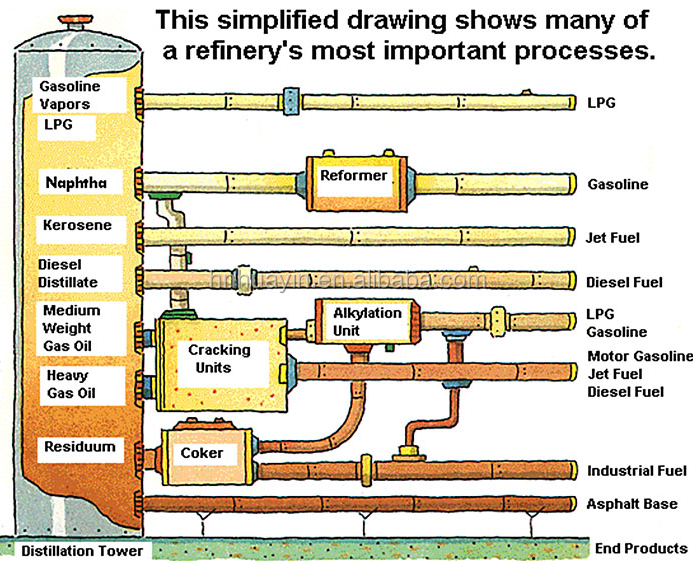

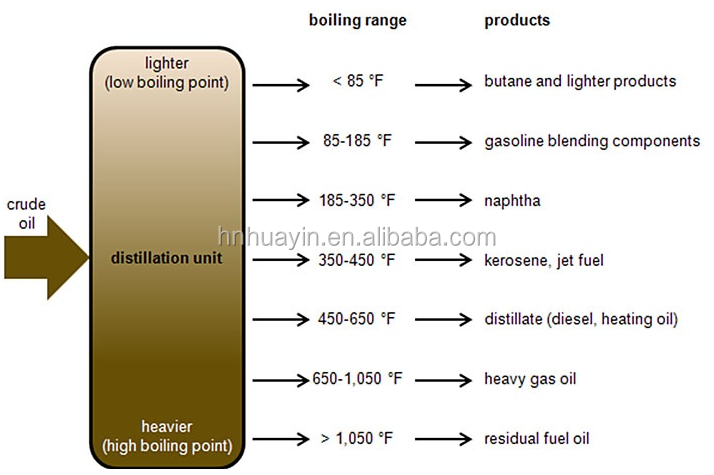

Distillation is the chemical engineering processes and other facilities used in oil refineries to distills the incoming crude oil, pyrolysis oil and waste oil into useful products such as diesel oil and fuel oils, gasoline or petrol, jet fuel, etc.

The distillation plant is used for recycling the tyre pyrolysis oil , plastic pyrolysis oil , engine oil , motor oil ,crude oil to diesel oil with yellow color.

Refining of crude oils or petroleum essentially consist of primary separation process and secondary conversion processes.The petroleum refining process is the separation of the different hydrocarbons present in the crude oil into useful fractions and the conversion of some of the hydrocarbons into products having higher quality performance. Atmospheric and vacuum distillation of crude oils is the main primary separation processes producing various straight run products, e,g., gasoline to lube oils/vacuum gas oils(VGO). These products, particularly the light and middle distillates, i.e, gasoline , kerosene and diesel are more in demand than their direct availability from crude oils, all over the world.

2. PROCESS DESCRIPTION FOR MINI OIL REFINERY FOR SALE

The whole process are consist of two process, VDU and ATMOSPHERIC COLUMN

1) ATMOSPHERIC COLUMN

Preheating of Desalted crude

Preflash

Distillation

Stabilization of Naphtha

PRODUCT OF ADU : Major product from atmospheric column are light gases and LPG, light naphtha, medium naptha, heavy naphtha, kerosene, gas Oil (diesel), atmospheric residue.

2) VACUUM DISTILLATION COLUMN(VDU)

The bottom product also called reduced crude oil, from the atmospheric column is fractionated in the vacuum column. Reduced crdue oil is very heavy compared to crude oil distillating under pressure requires high temperature. Distillation under vacuum permits fractionation at lower temperature which avoid cracking of the reduced crude oil and cokng of the furnace tube. Vacuum is maintained using three stage steam ejector.

PRODUCTS FROM VDU: various products from VDU are light gasoil, heavy gas oil, light lube distillate , medium lube distillate, heavy lube distillate and vacuum column residue.

| Item | Contents | |

| Input-Raw Materials | Waste engine/motor oil/Plastic pyrolysis oil/Tire pyrolysis oil/Lubrication oil/CRUDE OIL | |

| Average out-put oil rate | 85%-90% | |

| End products | Diesel oil, waste gas, slag | |

| Structure form | Horizontal | |

| Operating pressure | Constant pressure | |

| Heating material | Coal, charcoal, fuel gas, fuel oil | |

| Model(Diameter*Length)(mm) | Reactor size | Capacity |

| D1500*L3000 | 3 Ton/Day | |

| D2000*L5000 | 5 Ton/Day | |

| D2800*L6000 | 10 Ton/Day | |

| Material of reactor | Q245R&Q345R boiler plate | |

| Thickness of reactor | 16mm, 18mm | |

| Mode of cooling | Circulating water cooling | |

| Space needed | Length: 30m, Width :10 m at most | |

| Power consumption | Average 15 KW/h | |

3. MAIN PARTS FOR MINI OIL REFINERY EQUIPMENT

a. distillation reactor

b. condensers

c. heat exchanger

d. dedusting device

e. saftey device

f. distillation column

g. oil tanks oil pumps

h. vcuume pump

4. MAIN FEATURES FOR MINI OIL REFINERY EQUIPMENT

1> Unique horizontal design with high oil yield reach to 90%.

High effective and high profit.

Mobile design for the condensing parts and dedusting parts, has advantage of fast installation.

2> Safety

a:Adopting automatic submerged-arc welding technology

b:All of the welding place will be detected by the ultrasonic nondestructive testing method to ensure the welding quality and the welding shape.

c:Adopt manufacture process controlling system on the quality, every manufacture process, manufacture date, etc.

d:Equipped with anti explosion device, safety valves, emergency valves, pressure and temperature meters, as well as the alarming system.

3>Environmental-friendly

a: Emission Standard: Adopting special gas scrubbers to remove acid gas and dust from smoke

b: Smell during operation: Fully enclosed during the operation,there is no bad smell out.

c: Water pollution: No pollution at all.

4>Energy conservation and low cost on operation

Special covers of the reactors and chambers can keep hot during the heating in good efficiency as well as the direct heating system to save energy and cost

5. OUR ADVANTAGE

1. Low cost, cost is 30$ for refine one tons used oil.

2. Easy to operate,low operation cost, only 2 workers can control the machine.

3. The machine can recycle pyrolysis oil , crude oil ,used motor oil , all kinds of engine oil, and other lubricant oil to clean diesel oil.

4. Environmental friendly. This machine is full enclosed, there is no any harmful smell come out form the machine

6. OUTPUT PRODUCT SHOW

The diesel oil produced by the distillation machine can be used for diesel engines like trucks ,t ractors , ships , power generators etc.

7. OUR SERVICE

1>Pre-Sales Service

1.24 hours online .Your inquiry will be quick reply by email .

2. Sample testing support.

3. View our Factory.

4. Professionally and patiently introduction,details pictures and working video to show machine

2>After-Sales Service

1. 1 year warranty, engineers available to service at any time

2. Periodical call visit, to make sure there is no problems of the equipment

3. Design specific maintinance program according to different situation of your plant

8.ABOUT US

Xinxiang Huayin Renewable Energy Equipment Co., Ltd has been specializing in manufacturing waste management equipments for 20 years. our machine has been exported to over 50 countries including Romania, Hungary, Russia, Turkey, Slovakia,Ecuador, Guatemala, Haiti, Mexico, Peru,Canada and USA,Jordan, UAE, Lebanon, Kuwait etc.

Our Main products have used plastic recycling machine to oil , plastic pyrolysis plant production line , waste scrap tyres pyrolysis machine , pyrolysis oil distillation equipment /plant , engine oil recycling machine to diesel machinery.

HUAYIN has formal production lines with clear division of work, technical laboratory with the ability to test various parameters of oil products,We treat security as the first principle in the production, meanwhile make efforts on quality, environmental protection, automation, energy conservation and high oil yield.

We have certificates of ISO9001, ISO14001, CE, and patents for our equipment.

iF YOU ARE INTERESTED IN THIS WASTE OIL RECYCLING / OIL REFINING MACHINE , PLEASE SEND US INQUIRY SOON !