- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

hong jin

-

Year:

-

2023

-

Weight (T):

-

0.2 T

-

Motor Power (kw):

-

5.5 kw

-

Product name:

-

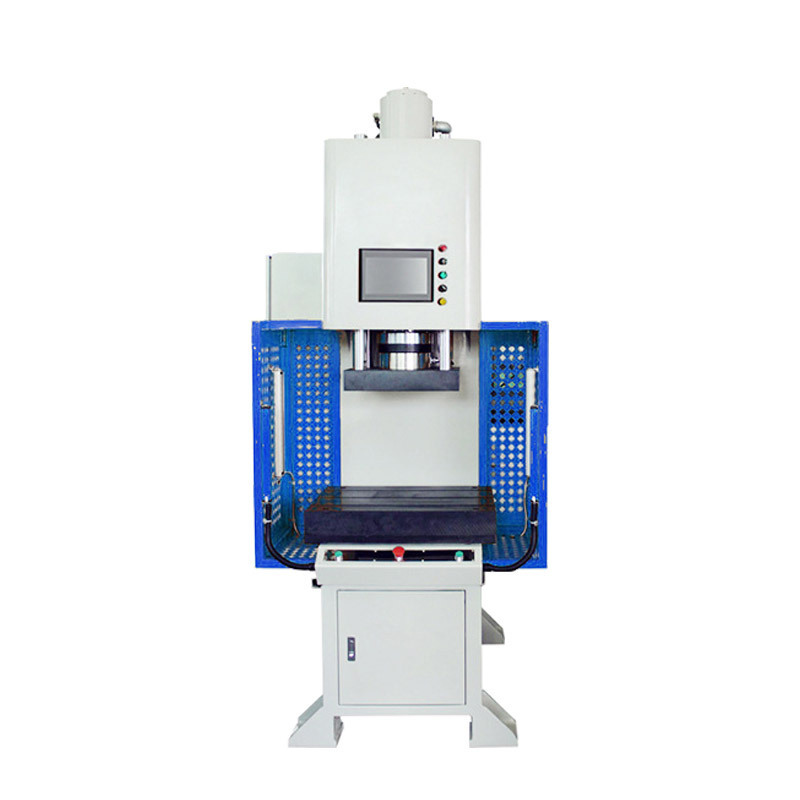

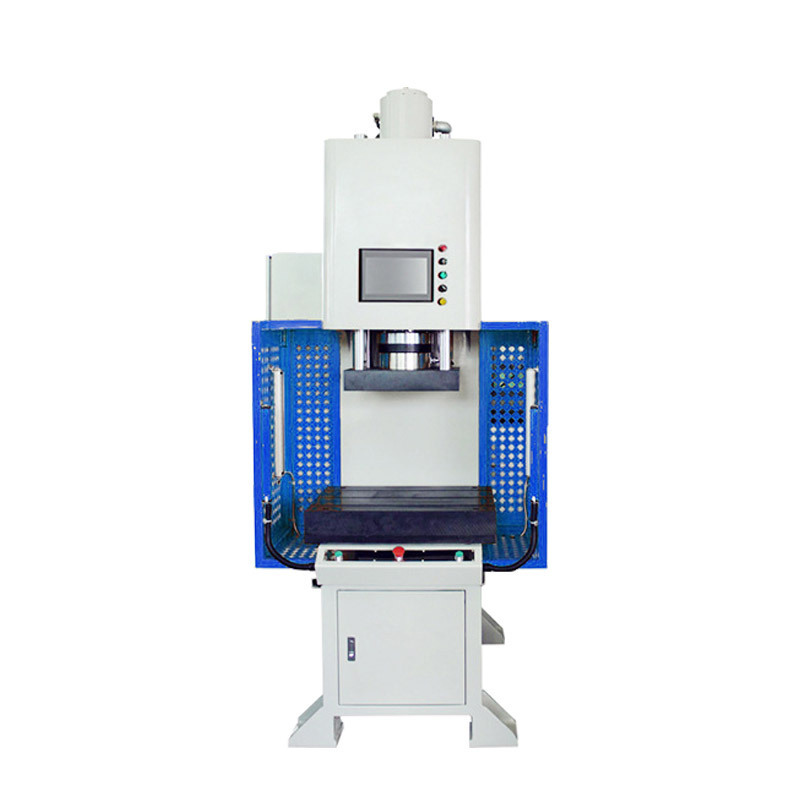

Automobile bearing servo press machine

-

Application:

-

Widely

-

Color:

-

Customer Required

-

Power supply:

-

220V 50Hz

-

Model:

-

Coustomization

-

MOQ:

-

1 Set

-

Brand:

-

Hong Jin

-

Port:

-

Shen Zhen

-

Delivery time:

-

7-15days

Quick Details

-

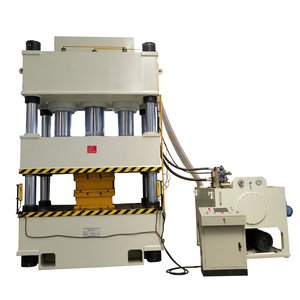

Machine Type:

-

Four-column Two-beam Hydraulic Press

-

Slide Stroke (mm):

-

300

-

Return Force (kN):

-

10 kN

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

hong jin

-

Year:

-

2023

-

Weight (T):

-

0.2 T

-

Motor Power (kw):

-

5.5 kw

-

Product name:

-

Automobile bearing servo press machine

-

Application:

-

Widely

-

Color:

-

Customer Required

-

Power supply:

-

220V 50Hz

-

Model:

-

Coustomization

-

MOQ:

-

1 Set

-

Brand:

-

Hong Jin

-

Port:

-

Shen Zhen

-

Delivery time:

-

7-15days

Product Paramenters

Product Introduction

Special servo press assembly testing machine for automobile bearings Widely used, while focusing on the automotive industry, we also provide automatic assembly equipment for the electric machine industry, white goods industry, wind power new energy industry, electronic and and other industries. Bearing press assembly is a scene which is widely used in servo press, especially in automobile and motor industry which require high quality assembly operation.

Performance characteristics:

1. Compared with the traditional pneumatic and hydraulic presses, the energy-saving effect is more

than 80%, and it is more environmentally friendly and safe, which can meet the requirements of equipment use in the dust-free workshop;

than 80%, and it is more environmentally friendly and safe, which can meet the requirements of equipment use in the dust-free workshop;

2. The whole process curve of pressing force and displacement can be displayed on the LCD touch screen; The whole

process control can automatically determine whether the product is qualified at any stage in the process of operation, 100% real-time removal of defective products, so as to achieve online quality management:

process control can automatically determine whether the product is qualified at any stage in the process of operation, 100% real-time removal of defective products, so as to achieve online quality management:

3. Pressing force, pressing depth, pressure speed, pressure holding time and other values can be entered on the operation panel with friendly interface and simple operation

4. Can customize, store, call pressure installation program 100 sets; Seven kinds of pressing modes are available to meet your different process needs;

4. Can customize, store, call pressure installation program 100 sets; Seven kinds of pressing modes are available to meet your different process needs;

5. Through the external port connected to the computer, the press data can be stored in the computer, to ensure the traceability of product processing data, convenient production quality control management;

6, because the machine itself has the correct pressure and displacement control function, so there is no need to add a hard limit on the tooling, processing different specifications of products only need to call different press assembly procedures, so it can easily achieve a multi-purpose machine and flexible line

Products Description

Hot Searches