- Product Details

- {{item.text}}

Quick Details

-

Thickness:

-

0.3 mm - 3.0 mm

-

Length:

-

2000mm, 2438mm, 3048mm,

-

Width:

-

1000mm, 1219mm, 1500mm

-

SS Grade:

-

304,316, 201,430 etc

-

Surface Treatment:

-

2B, No.1, BA,, No.4, PVD

-

MOQ:

-

1TON

-

Application:

-

aerospace, automotive, manufacturing, oil and gas,

-

Packing way:

-

PVC+ waterproof paper + strong sea-worthy wooden package

-

Keyword:

-

stainless steel

Quick Details

-

Surface Finish:

-

2B

-

Place of Origin:

-

China

-

Products Name:

-

Stainless steel Coil

-

Thickness:

-

0.3 mm - 3.0 mm

-

Length:

-

2000mm, 2438mm, 3048mm,

-

Width:

-

1000mm, 1219mm, 1500mm

-

SS Grade:

-

304,316, 201,430 etc

-

Surface Treatment:

-

2B, No.1, BA,, No.4, PVD

-

MOQ:

-

1TON

-

Application:

-

aerospace, automotive, manufacturing, oil and gas,

-

Packing way:

-

PVC+ waterproof paper + strong sea-worthy wooden package

-

Keyword:

-

stainless steel

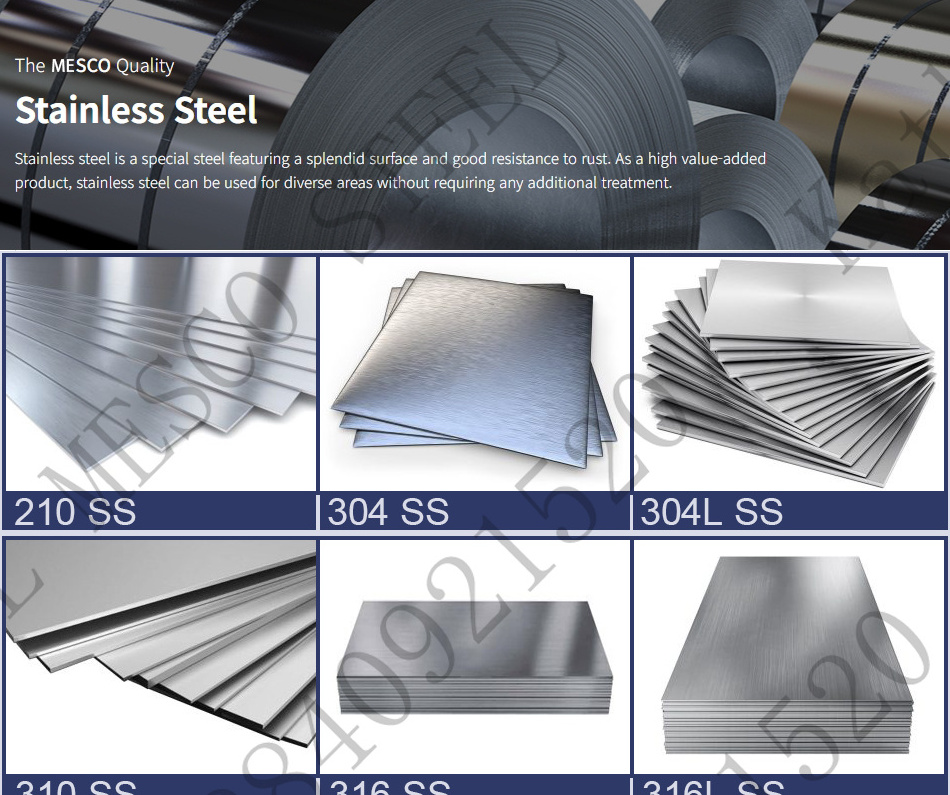

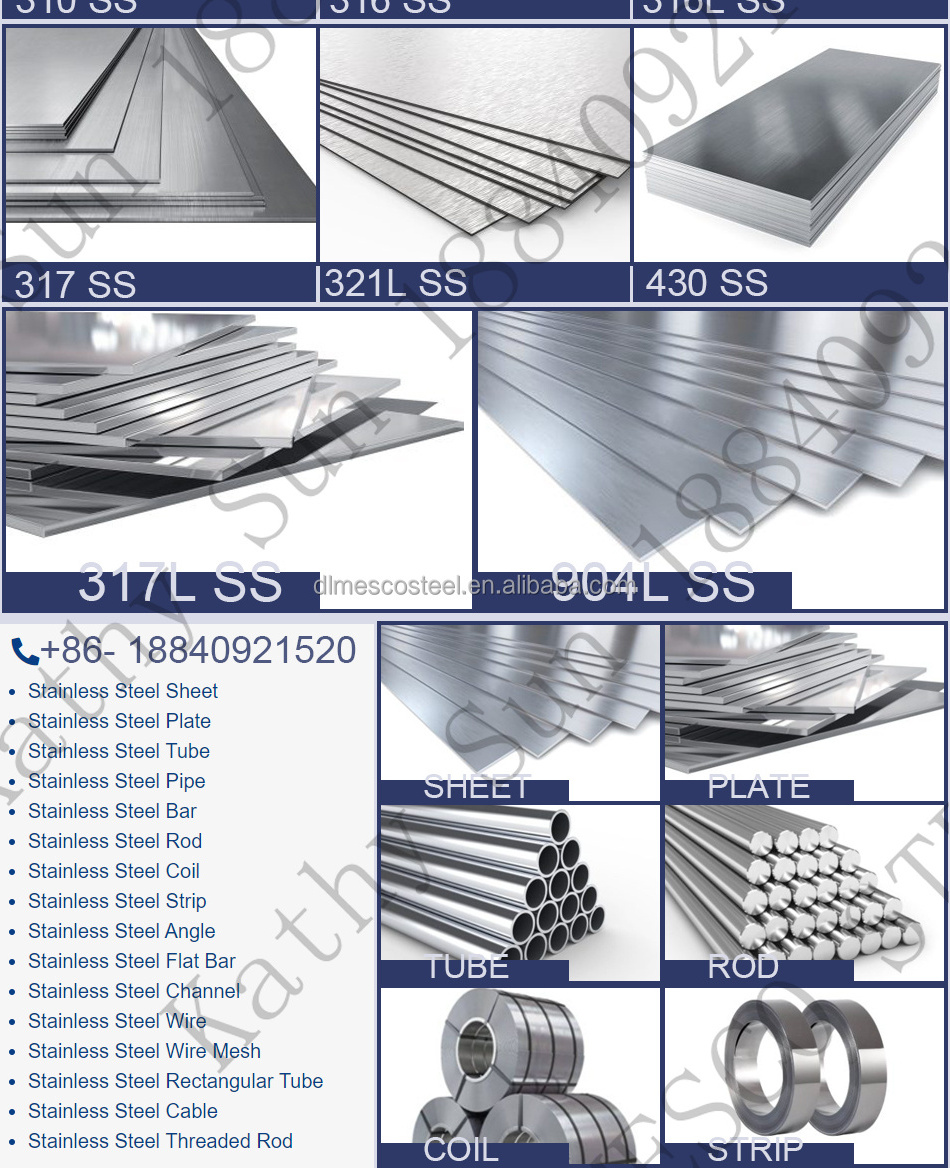

Product Overview

Stainless Steel

Stainless steel is a steel alloy that must contain a minimum of 10.5% chromium and contains levels of nickel, molybdenum, and niobium.

Compared to regular steel, stainless steel does not easily corrode, stain, or oxidize/rust. Stainless steel is available from

Continental Steel in an extensive range of forms, grades, finishes, gauges, widths, and lengths.

Many different industries rely on stainless steel for a wide range of applications including aerospace, automotive, manufacturing, oil and gas, and many more. If you cannot find the exact type of stainless steel you are looking for, please call or contact us.

Continental Steel in an extensive range of forms, grades, finishes, gauges, widths, and lengths.

Many different industries rely on stainless steel for a wide range of applications including aerospace, automotive, manufacturing, oil and gas, and many more. If you cannot find the exact type of stainless steel you are looking for, please call or contact us.

AISI、ASTM

SS Grade:

301,S30100 304,S30400 304L,S30403 305 321,S32100 316,S31600 316N,S31651 316L,S31603 317,S31700 317L,S31703 347,S34700 310s,S31008

201, 202, 301, 302, 303, 304, 304L, 304H, 310S, 316, 316L, 317L, 321,310S 309S, 410, 410S,420, 430, 431, 440A,904L Stainless Steel Coil

Нержавеющая сталь

Нержавеющая сталь - это сплав стали, который должен содержать не менее 10,5% хрома, а также никель, молибден и ниобий.

По сравнению с обычной сталью, нержавеющая сталь не подвержена легкой коррозии, пятнам или окислению/ржавчине. Нержавеющая сталь доступна от Continental Steel в широком ассортименте форм, марок, отделок, толщин, ширин и длин.

Многие различные отрасли промышленности полагаются на нержавеющую сталь для широкого спектра применений, включая аэрокосмическую, автомобильную, производственную, нефтегазовую и многие другие. Если вы не можете найти именно тот тип нержавеющей стали, который вам нужен, позвоните или свяжитесь с нами.

AISI, ASTM SS Grade: 301, S30100 304, S30400 304L, S30403 305 321, S32100 316, S31600 316N, S31651 316L, S31603 317, S31700 317L, S31703 347, S34700 310s, S31008

201, 202, 301, 302, 303, 304, 304L, 304H, 310S, 316, 316L, 317L, 321,310S 309S, 410, 410S,420, 430, 431, 440A,904L Stainless Steel Coil

Austenitic Series(300 Series)

This stainless steel is the most widely used of all its kinds. It contains chrome and nickel and features good formability,

weldability and anti-corrosion. The most common austenitic stainless steel is Type 304. There are also other notable austenitic

stainless steels-Types 316L, 321 and 304J1 to name a few-produced by adding different alloy elements such as Mo, Ti and Cu. Main

applications of austenitic stainless steel include kitchen utensils, construction and chemical instruments.

Related Industries

EV Battery Pack Exhaust System Interior and Exterior Ship Plant & Storage Kitchen Appliances

weldability and anti-corrosion. The most common austenitic stainless steel is Type 304. There are also other notable austenitic

stainless steels-Types 316L, 321 and 304J1 to name a few-produced by adding different alloy elements such as Mo, Ti and Cu. Main

applications of austenitic stainless steel include kitchen utensils, construction and chemical instruments.

301/301L

The main chemical composition of Type 301 is 17Cr - 7Ni and Type 301L is 17Cr - 7Ni - LC. This stainless steel contains less Cr and Ni than Type 304 and can have higher strength through hot rolling.

Applications

304

Applications

Its common applications include springs and rolling stock.

304

The main chemical composition of Type 304 is 18Cr - 8Ni. The most extensively used stainless steel featuring good resistance to corrosion and heat among other mechanical properties.

Applications

Applications

Major applications include home appliances, construction and kitchen appliances.

304L

The main chemical composition is 18Cr - 9Ni - LC. This stainless steel contains less carbon than 304 and has good resistance to intergranular corrosion.

Applications

Applications

Its common applications include industrial machines, chemical facilities and LNG tanks.

304J1

The main chemical composition is 17Cr - 8Ni - 2Cu. This stainless steel has good formability as it contains Cu.

Applications

Applications

Its common applications include kitchen sinks, vacuum flasks and deep drawing.

316

The main chemical composition is 18Cr - 12Ni - 2Mo.This stainless steel contains Mo and increased Ni to have good resistance to corrosion. It can also withstand high temperatures

Applications

Applications

Its common applications include water pipes, chemical plants and coastal facilities.

316L

The main chemical composition is 18Cr - 12Ni - 2Mo - LC. This stainless steel contains less carbon than 316 and, therefore, has good resistance to intergranular corrosion.

Applications

Applications

It is extensively used for applications exposed to sources of corrosion, such as salt and toxic gas.

316L

N

The main chemical composition is 18Cr - 11Ni - 2Mo - 0.13N (thick plates). This stainless steel is made by adding nitrogen to316L steel.

Applications

Its common applications include chemical plants and storage tanks.

321

The main chemical composition is 18Cr - 9Ni - 0.3Ti. This stainless steel is made by adding Ti to 304 steel for better

resistance to intergranular corrosion.

Applications

resistance to intergranular corrosion.

Applications

Its common applications include heat exchangers and boiler covers.

XM15J1

The main chemical composition is 19Cr - 13Ni - 3.5Si (cold rolled). This stainless steel contains Si for better resistance

to high-temperature salt corrosion and oxidation.

Applications

to high-temperature salt corrosion and oxidation.

Applications

Its common applications include car exhaust systems, heaters and incinerator components.

310S

The main chemical composition is 22Cr - 20Ni.This stainless steel contains increased Cr and Ni for good resistance to high-temperature oxidation and higher strength at high temperatures.

Applications

Applications

It is extensively used in applications requiring good resistance to heat including exhaust systems and heat

exchangers.

exchangers.

Ferritic Series(400 Series)

For ferritic steel, chrome is one of its alloy components. This gives the steel low thermal expansion and a good resistance to corrosion. The most common austenitic stainless steel is Type 430. There are also other notable austenitic stainless steels-Types

409L, 430J1L and 444 to name a few-produced by adding different alloy elements such as Ti, Nb and Mo. Its main applications include exhaust systems and home appliances.

Related Industries

Hydrogen Fuel Cell Exhaust System Interior and Exterior Kitchen Appliances

430

The main chemical composition is 16Cr - 0.05C. The most commonly used ferritic stainless steel featuring good formability and resistance to oxidation

Applications

Applications

Its typical applications include kitchen appliances, utensils and architectural materials.

409L

The main chemical composition is 11Cr - 02Ti - LCN. This stainless steel contains Ti for better weldability and machinability.

Applications

Applications

Its common applications include car exhaust systems, heat exchangers and heat resisting wares.

410L

The main chemical composition is 12Cr - LCN. This stainless steel is basically 410 steel, but with a reduced carbon content for better weldability, toughness and machinability.

Applications

Its typical uses include containers and architectural materials.

429EM

The main chemical composition is 14Cr - 1Si - 0.2Ti - LC. This product contains newly added Si, Ti, Mn, Cu and others and reduced C and N for better strength at high temperatures, better resistance to oxidation and improved formability.

Applications

Applications

Its typical applications include car exhaust systems and heat resisting wares.

430J1LThe main chemical composition is 19Cr - 0.5Cu - 0.4Nb - LCN. This product is made by adding Cu and Nb to 430 steel for better resistance to corrosion, better formability and weldability as well as improved properties at high temperatures.

Applications

Applications

Its common uses include washing tubs, kitchen appliances, home appliances and heat resisting wares.

436L

The main chemical composition is 18Cr - 1Mo - 0.3Ti - LCN. Addition of Mo, Ti and Nb assures good resistance to corrosion, machinability and weldability.

Applications

Applications

Its typical uses include car exhaust systems, heat resisting ware and hot water wares.

439

The main chemical composition is 18Cr - 0.4Ti - LCN. This stainless steel contains Ti that can improve resistance to corrosion, machinability and weldability.

Applications

Applications

Its typical applications include car exhaust systems and architectural materials.

444

The main chemical composition is 19Cr - 2Mo - 0.3Nb - LCN. This product contains high Cr and Mo that can improve resistance to intergranular corrosion and stress corrosion cracking.

Applications

Applications

Its common uses include water tanks and water heating systems.

445NF

The main chemical composition is 21Cr - 0.3Ti - 0.4Cu - Si,Nb. This high Cr content stainless steel has good resistance to

corrosion and good formability.

Applications

corrosion and good formability.

Applications

It is used for wide applications including elevators, utensils and architectural materials.

446M

The main chemical composition is 26Cr - 2Mo - 0.3 (Ti, Nb) - LCN (cold rolling). This product contains high Cr and Mo that can improve resistance to corrosion.

Applications

Applications

Its common uses include exterior walls and roofs on coastal areas.

Martensitic Series

Martensitic steel contains 12 percent of chrome. Its higher content of carbon compared to other types of steel can give it greater hardness through quenched heat treatment. Its main applications include cutlery and disc brakes.

Related Industries

Related Industries

Machine Structure Kitchen Appliances

Duplex Series

Duplex steel combines austenitic and ferritic steels to provide higher strength and better resistance to corrosion. It is

extensively used for industrial purposes including water tanks and desalination installations.

Related Industries

extensively used for industrial purposes including water tanks and desalination installations.

Related Industries

Plant & Storage

SALES AND SERVICE NETWORK

Successful Project

Hot Searches