- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Huan Machinery

-

Year:

-

Customized

-

Voltage:

-

220V/380V/Customized

-

Dimension(L*W*H):

-

11.5*9*6.9m

-

Hollow part volume:

-

200L

-

Screw L/D Ratio:

-

30

-

Screw diameter (mm):

-

120 mm

-

Screw Heating Power(kW):

-

47 kW

-

Extruder Motor Power(kW):

-

132 kW

-

Mold Platen Size(Width)(mm):

-

950 mm

-

Mold Platen Size(Height)(mm):

-

1600 mm

-

Air Pressure(MPa):

-

1 MPa

-

Air Comsumption(m³/min):

-

1.8 m³/min

-

Die Head Heating Power(kW):

-

38 kW

-

Accumulator Capacity(L):

-

20 L

-

Power (kW):

-

307

-

Weight (T):

-

35

-

Product name:

-

chemical drum making machine

-

Blow Moulding Type:

-

Extrusion Blow Moulding

-

Automatic:

-

Yes

-

Product possible:

-

water tank, container,drum, barrel, pallet, etc.

-

Material:

-

HDPE, PE, PP, etc

-

Machine type:

-

chemical barrel making machine

-

Key words:

-

plastic chemical drum making machine

Quick Details

-

Clamping Force (kN):

-

1500

-

Output (kg/h):

-

380 kg/h

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Huan Machinery

-

Year:

-

Customized

-

Voltage:

-

220V/380V/Customized

-

Dimension(L*W*H):

-

11.5*9*6.9m

-

Hollow part volume:

-

200L

-

Screw L/D Ratio:

-

30

-

Screw diameter (mm):

-

120 mm

-

Screw Heating Power(kW):

-

47 kW

-

Extruder Motor Power(kW):

-

132 kW

-

Mold Platen Size(Width)(mm):

-

950 mm

-

Mold Platen Size(Height)(mm):

-

1600 mm

-

Air Pressure(MPa):

-

1 MPa

-

Air Comsumption(m³/min):

-

1.8 m³/min

-

Die Head Heating Power(kW):

-

38 kW

-

Accumulator Capacity(L):

-

20 L

-

Power (kW):

-

307

-

Weight (T):

-

35

-

Product name:

-

chemical drum making machine

-

Blow Moulding Type:

-

Extrusion Blow Moulding

-

Automatic:

-

Yes

-

Product possible:

-

water tank, container,drum, barrel, pallet, etc.

-

Material:

-

HDPE, PE, PP, etc

-

Machine type:

-

chemical barrel making machine

-

Key words:

-

plastic chemical drum making machine

Product Overview

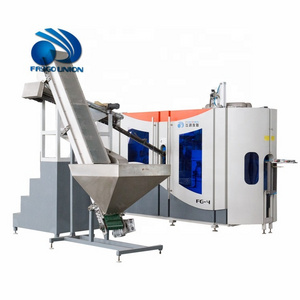

High speed plastic blue 200l flanged drum machine line 55 gallon drums blow molding machine

It is accumulating machine for producing HDPE, HMWHDPE chemical, food, liquid plastic products, like 30L, 60L, 120L, 200L,220l jerrycan, plastic container, oil drum, barrel... Besides, it also could produce some different shapes plastic products like toys, road barrier, human body model or others...

|

Name

|

Supplier

|

|

|

|

Hydraulic Servo Motor

|

PHASE/ Italy

|

|

|

|

Oil Pump

|

SUMITOMO / JAPAN

|

|

|

|

Hydraulic Valve

|

YUKEN/ JAPAN

|

|

|

|

Servo Valve

|

ATOS/ Italy

|

|

|

|

Parison control system

|

MOOG/JAPAN

|

|

|

Product Details

Mould

Blow molding molds are key components used in shaping molten plastic into hollow products. They consist of cavity and core halves that define the product's shape. Proper mold selection and maintenance are crucial for quality production. Understanding blow molding molds is essential for successful plastic manufacturing.

Die head

This type of die head is commonly used in blow molding processes to ensure a continuous and uniform flow of molten plastic. It features a storage cylinder that stores a certain amount of material before it is pushed into the mold cavity. This design allows for efficient material distribution and control, resulting in consistent product quality and improved production efficiency.

Extrusion System

The key component in blow molding, the extrusion system melts and shapes plastic material. It includes an extruder and a screw or ram to push molten plastic through the die head. It accommodates single-layer, double-layer, or triple-layer extrusion for product versatility. Different layers can be made from diverse materials, enhancing strength, barrier properties, or aesthetics. Choose the appropriate extrusion system based on specific product needs.

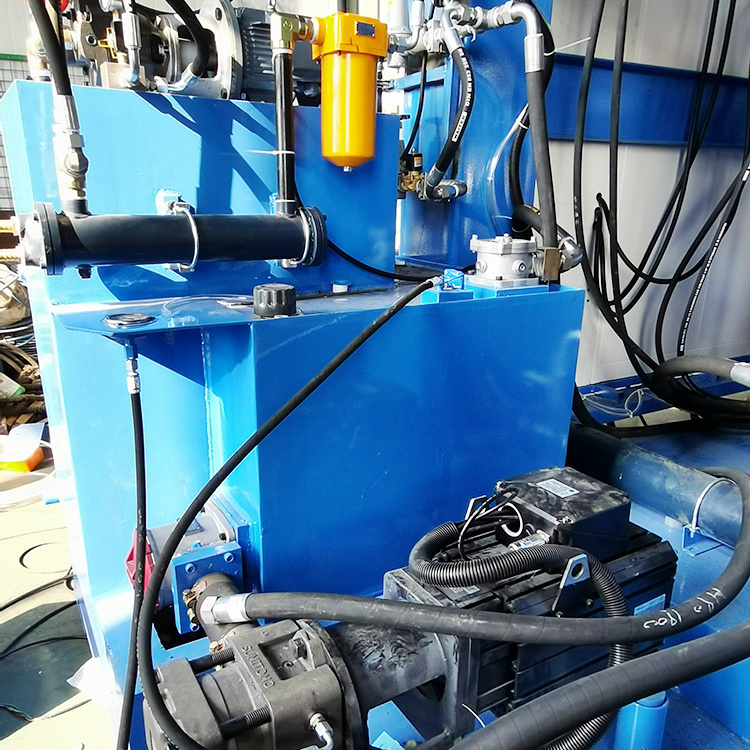

Hydraulic System

Reliable and Efficient: Our blow molding machines feature a high-performance hydraulic system with top-quality components, including YUKEN valves and pumps, SIMENS BEDE motors, valve blocks, oil coolers, and cylinders. This advanced system controls all machine actions, ensuring precise movements and optimal performance. Trust in our hydraulic system for reliable and efficient operation of your blow molding processes.

Electrical System

Powerful and Dependable: Our blow molding machines are equipped with a robust electrical system that guarantees smooth and reliable operation. The electrical system includes high-quality components, such as advanced control panels, top-rated circuit breakers, and premium wiring. With a focus on safety and efficiency, our electrical system ensures precise control over all machine functions, providing you with consistent and high-quality results. Rely on our cutting-edge electrical system to power your blow molding production with confidence.

Clamping structure

Robust Clamping: Our blow molding machines feature a sturdy clamping structure that ensures secure and stable operations. Engineered with precision and built to last, our clamping system delivers uniform force distribution for reliable production. With top-quality materials and reliable mechanical components, our clamping structure guarantees consistent performance and durability. Experience the confidence of producing high-quality blow molded products with our advanced clamping technology.

How to Produce 200L Wide Neck Blue Drum?

If you want to know more details about hdpe drum production line, please feel free to contact us by Alibaba.

Hot Searches