- Product Details

- {{item.text}}

Quick Details

-

Max. Loading Capacity:

-

4000, 4000L

-

Weight (KG):

-

200 KG

-

Place of Origin:

-

Henan, China

-

Voltage:

-

220V 380V

-

Dimension(L*W*H):

-

1200*500*950, 1200*500*950

-

Power (kW):

-

1.5 kW

-

Product name:

-

Trough type blender

Quick Details

-

Barrel Volume (L):

-

50L-5000L

-

Max. Loading Volume (L):

-

4000 L

-

Range of Spindle Speed(r.p.m):

-

0 - 25 r.p.m, 0 - 24 r.p.m

-

Max. Loading Capacity:

-

4000, 4000L

-

Weight (KG):

-

200 KG

-

Place of Origin:

-

Henan, China

-

Voltage:

-

220V 380V

-

Dimension(L*W*H):

-

1200*500*950, 1200*500*950

-

Power (kW):

-

1.5 kW

-

Product name:

-

Trough type blender

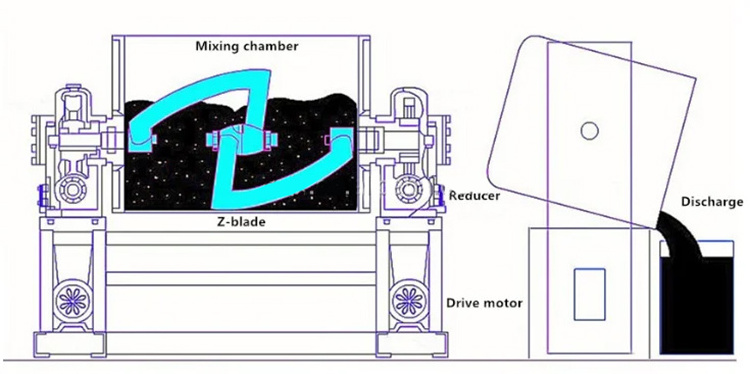

Z blade mixer is widely used for mixing wet powders, pastes and slurries with low and medium viscosity in food, chemical for small to medium scale production.It consists of trough-shaped mixing bowl, single or double sigma blade, drive motor, tilt motor and support frame. Materials are gravity fed into the mixing bowl. The rotary Z blades completely stir and blend the materials to achieve uniform mixing. After mixing, tilt the mixing bowl for discharging. Heavy duty Double sigma/Z blade mixer is also available for mixing dough and other pasty products with medium to high viscosity.

Working Principle

(1) Z arm type paddle is rotated, through mechanical driving, which pushes the material turn repeatedly and mix uniformly.

(2) Operated with electrical control, we can set mixing time to realize automatic stop and electric drive to discharge, thus improving the mix quality of each batch of material and realizing the high homogeneous mixing.

Main Technology Parameters:

|

Model

|

VBT-50

|

VBT-100

|

VBT-200

|

VBT-300

|

VBT-400

|

VBT-500

|

|||||

|

Total volume(L)

|

50

|

100

|

200

|

300

|

400

|

500

|

|||||

|

Mixing rotate speed(r/min)

|

24

|

|

|

|

|

|

|||||

|

Through rotation angle

|

<105°

|

|

|

|

|

|

|||||

|

Mixing motor power(kw)

|

1.5

|

2.2

|

4

|

5.5

|

5.5

|

7.5

|

|||||

|

Pouring motor power(kw)

|

0.37

|

0.55

|

0.75

|

1.1

|

1.1

|

1.5

|

|||||

Technical advantages :

1. Robust, simple and compact design requires minimum maintenace ;

2. Made by SUS304 or SUS 316 and mirror polished to meet GMP pharmaceutic sanitary standards ;

3. Special drive shaft sealing design can 100% make sure contamination free of product ;

4. The gap between sigma blade and mixing vessel inner wall is less than 3mm ;

5. High efficient mixing without dead corner ;

6. Heating jacket can be equipped for steam, hot water or hot oil.

Henan vibrate Machinery is a production of food, chemical equipment enterprises, located in Henan Xinxiang City. We design custom solutions for the production, washing, cutting, meat processing, packaging and filling of vegetables, spices, meat, liquids, powders and pellets in many industries such as food, pharmaceutical, plastics, chemical, etc. Our main products include: packaging machines, filling machines, cleaning machines, cutting machines, meat processing machines and related products. the company has passed iso9001 quality management system certification and SGS certification, and all products have passed CE certification.

At present, the products have been exported to 96 countries and regions.

We also have in-depth cooperation with local agents in key markets such as Indonesia, Malaysia, Singapore, Thailand, India, Vietnam, Brazil, Australia, France, United Kingdom, Hungary, etc., to provide localized after-sales service and technical support.

Our Certification

Q: 1. Are you a manufacturer, trading company or third party?

A: We are a manufacturer, located in the high-tech zone of Xinxiang City, Henan Province, China. You are warmly welcome to visit our company.

Q:2. What is your minimum order quantity and can you send me samples?

A: Our MOQ is 1 set, because our products are mechanical equipments, so it is difficult to send you samples, if you have any questions about the products, please feel free to contact us for more details, we will be happy to provide you with more information, such as specifications, videos and so on.

Q:3. How does your factory perform quality control?

A:

(1) All raw materials we use are environmentally friendly.

(2) Skilled workers pay attention to every detail during production and packaging.

(3) The quality control department specializes in the quality of each process.36 Over the years, we continue to introduce advanced technology and provide high quality products, and our products are also widely exported to many countries, such as Russia, Middle East, Africa, Southeast Asia, and the European Union, and we have won a high reputation among our customers.

Q: 4. What is the delivery time of your machines?

A: Generally speaking, the delivery period of our machines is about 30 days, and the customized machines will be delivered according to the negotiation with customers.

Q: 5. How about after-sales service?

A:(1) TM is online 24 hours a day, also can be contacted by email, skype, MSN, whatsapp etc.

(2) Problem solving by video/picture.

(3) One year warranty for spare parts replacement. If you encounter any other problems, please feel free to contact us.

If you meet any other questions, please feel free to contact us.

click here.

Hot Searches