- Product Details

- {{item.text}}

Quick Details

-

Core Components:

-

MACHINE

-

Type:

-

manual chalk moulding machine

-

Capacity:

-

4000-8000 pcs/ h

-

Mold size:

-

800 pieces/per mold

-

Chalk size:

-

10 mm*8 mm* 75mm

-

Package size:

-

660*480*360(L*W*H)

-

Weight:

-

65kg

-

Operation method:

-

manual mixing

-

Number of mold:

-

1

-

Chalk shape:

-

Round

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Disen

-

Weight (KG):

-

35

-

Core Components:

-

MACHINE

-

Type:

-

manual chalk moulding machine

-

Capacity:

-

4000-8000 pcs/ h

-

Mold size:

-

800 pieces/per mold

-

Chalk size:

-

10 mm*8 mm* 75mm

-

Package size:

-

660*480*360(L*W*H)

-

Weight:

-

65kg

-

Operation method:

-

manual mixing

-

Number of mold:

-

1

-

Chalk shape:

-

Round

|

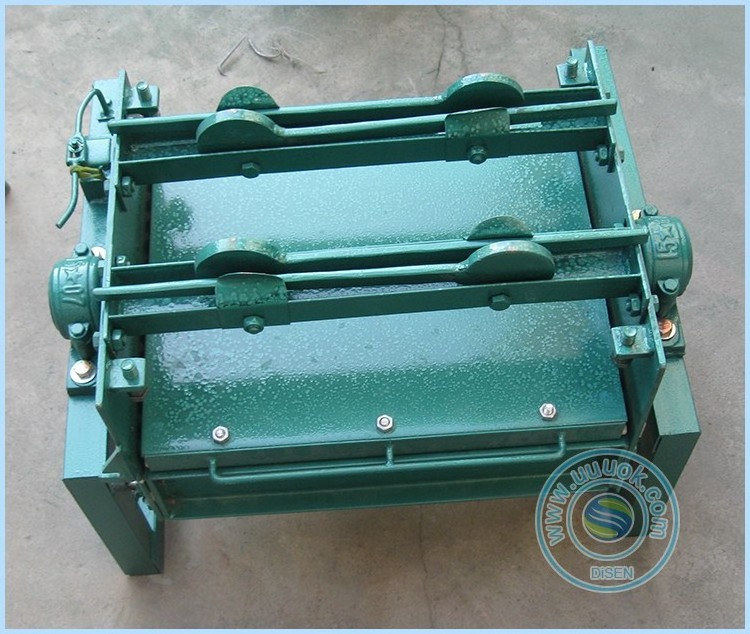

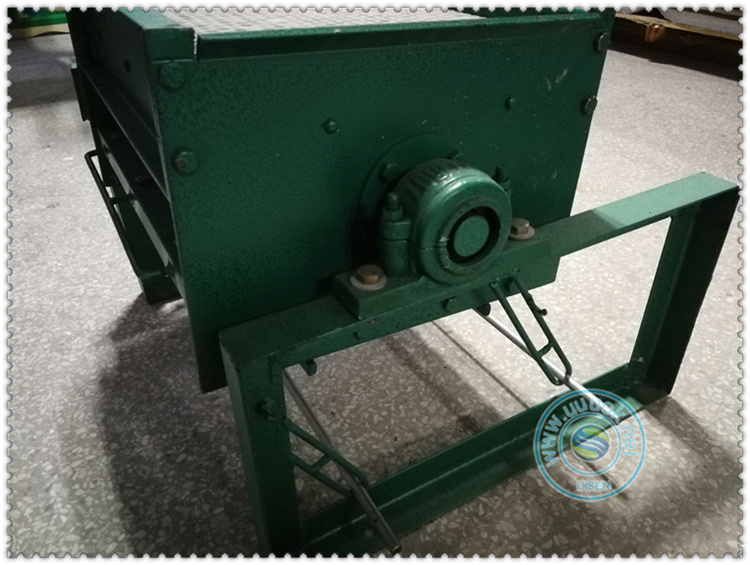

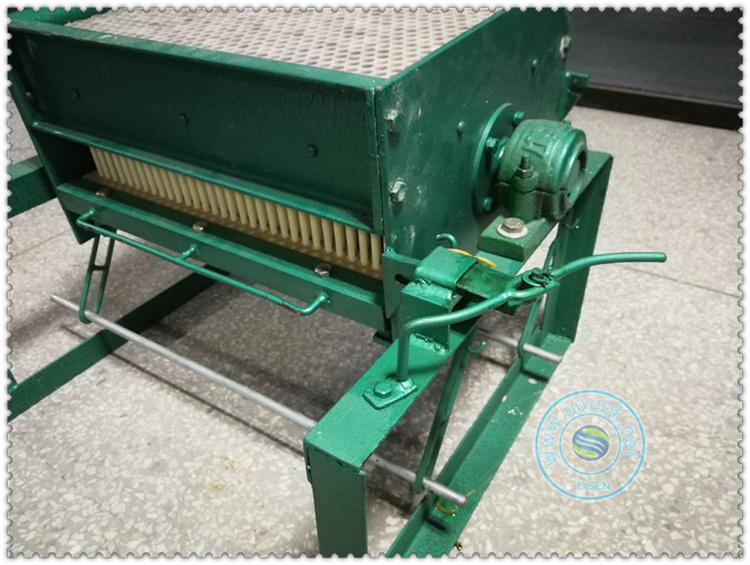

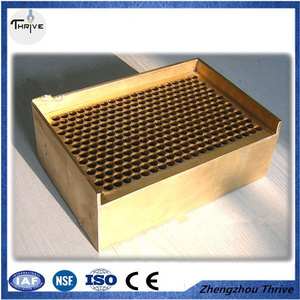

Specifications:

Durable dustless chalk machine

The FM-800 series chalk machine is the most advanced manufacturing production equipment of high quality at home.

Chalk production process 1. Mold evenly brush oil, brush back and forth with a wide brush, brush the new mold should be more oil. 2. The mold plate moving up and down a few times, the screw top and the bottom plate comes into contact. 3. Turn on the water, turn on the water with a movable foot switch pedal to pedal in the end, until the water in the water last. (First mold first feed, add water) 4. Addition, the quantitative good gypsum powder into the mixing bucket. 5. Mixing, stirring for 10-20 seconds to start the motor. 6. Put the pulp, put a good brush oil stirred to die bottom of the barrel, hit the switch to open the pulp slurry was stirred well into the mold until the stream last. 7. Calibrating with a plastic scraper to scrape the pulp mold hole, scrape out the remaining pulp mold mouth gelling. 8. A mold, a new mold die not too late. Chalk can feel a little hard to top 2-5 mm, 1 to 2 minutes over again ejection.

chalk making machine

|