- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Yutong

-

Voltage:

-

380V/220V/customizable

-

Power:

-

22kw

-

Dimension(L*W*H):

-

2300*2540*2700mm

-

Weight:

-

6100

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Color:

-

Customized

-

Model:

-

Z28-650

-

Thread Pitch:

-

1-12mm

-

Hydraulic Power:

-

7.5kw

-

Package:

-

Plywood Case

-

Inside diameter of rolling die:

-

100mm

-

Outside diameter of rolling die:

-

290mm

-

Work piece diameter:

-

30-120mm

-

Cooling power:

-

125w

Quick Details

-

Place of Origin:

-

Hebei, China

-

Application:

-

contrustion

-

Production Capacity:

-

100%

-

Brand Name:

-

Yutong

-

Voltage:

-

380V/220V/customizable

-

Power:

-

22kw

-

Dimension(L*W*H):

-

2300*2540*2700mm

-

Weight:

-

6100

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Color:

-

Customized

-

Model:

-

Z28-650

-

Thread Pitch:

-

1-12mm

-

Hydraulic Power:

-

7.5kw

-

Package:

-

Plywood Case

-

Inside diameter of rolling die:

-

100mm

-

Outside diameter of rolling die:

-

290mm

-

Work piece diameter:

-

30-120mm

-

Cooling power:

-

125w

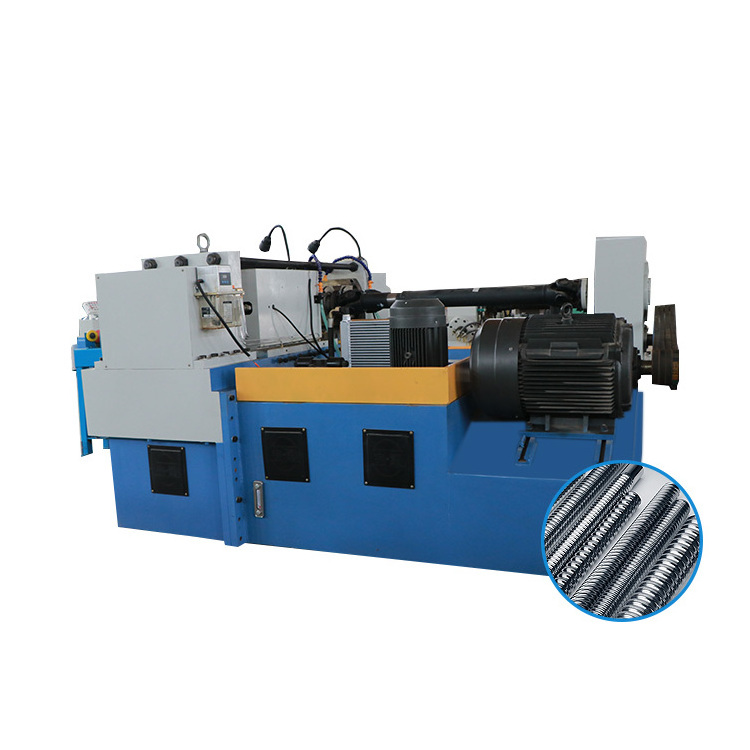

Product features: The machine is structurally strong, well-made, and powerful. It is mainly used for rolling various large trapezoidal threads, modular threads and high-strength standard parts. Suitable for rolling materials; various carbon steels with an elongation of more than 10% and a tensile strength of less than 100 N/mm2. Alloy steels and non-ferrous metals.

|

Max rolling pressure |

65 0KN |

Length |

Unlimited |

|

|

Rolling material diameter range |

Radial feed |

Φ 120 mm |

Spindle speed |

16, 26 , 38 , 55 , 90 (r/min) |

|

|

Axial feed |

Φ 120 mm |

|

|

|

Thread roller |

Outer roller diameter |

Φ 290 mm |

Active power |

22 kw |

|

|

Inner roller diameter |

Φ 100 mm |

Hydraulic power |

7.5 kw |

|

|

Max thickness of roller |

200 mm |

Cooling power |

0.125 w |

|

Axis tilt angle |

± 8 ° |

Weight |

6100 kg±50kg |

|

|

Spindle center distance |

300-410 mm |

Dimensions |

2500 × 2700 × 1500 mm |

|

|

Electrical cabinet size

|

800 × 500 × 1250mm |

|

||

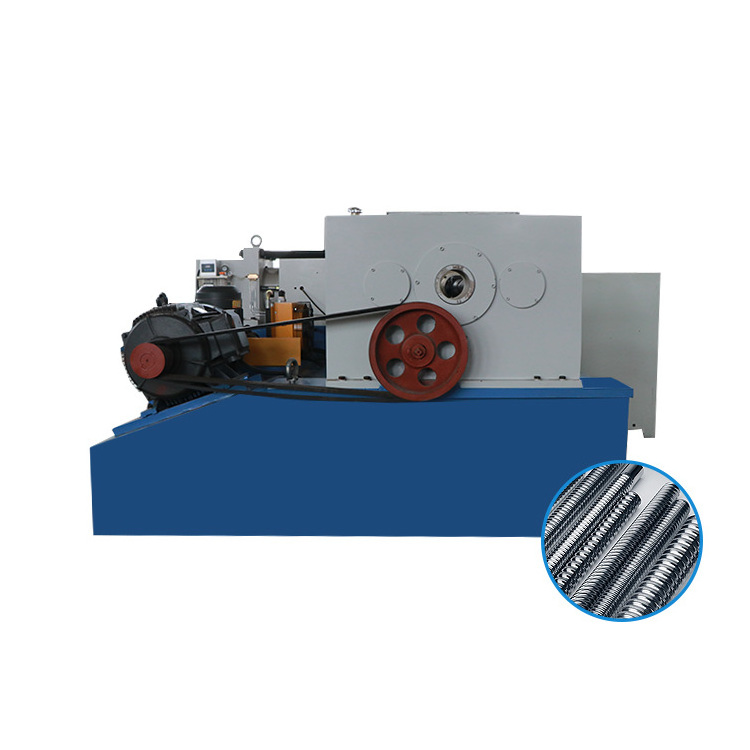

automatic rebar thread rolling machines is mainly used in the construction of ribbed steel bar straight screw thread processing, is to achieve reinforced straight thread connection process of key equipment.

automatic rebar thread rolling machines consists of frame, clamp, guide, slide, reducer, stripping rib rolling head, feeding mechanism, automatic opening and closing mechanism, stroke limit structure, cooling system, electrical control box and control system.

automatic rebar thread rolling machines is mainly used in the construction of ribbed steel bar straight screw thread processing, is to achieve reinforced straight thread connection process of key equipment.

automatic rebar thread rolling machines consists of frame, clamp, guide, slide, reducer, stripping rib rolling head, feeding mechanism, automatic opening and closing mechanism, stroke limit structure, cooling system, electrical control box and control system.

We have Many models thread rolling machine, Z28-40B, Z28-150, Z28-200, Z28-215, Z28-250, Z28-500,Z28-650 and so on.

All the diameter we can thread rolling, pls provice us the diameter and the type of your raw material, then i will recommed you the best model fit for you.

1.Q:Where are we located in?

A:We are in Xingwan Industrial Zone Xingtai city Hebei province,China.

2.Q:How is your factory?

A: We are factory specializing in the manufacture and export of machines for more than 20 years, all of the production we sale are at a very best price and high quality.

3.Q: What is your terms of packing?

A: Generally, we pack our goods in plywood cases.

4.Q:What is your terms of payment?

A: T/T 30% as deposit, and 70% balance against BL copy.

5.Q: Warrantee and After-sale service ?

A: 12 months warrantly, man-made destory will be exception.

B: After the warrantee time, we can supply materials or teach support to you for reducing the cost of you.

6.Q:Delivery time ?

A: 15-20 days for OEM, 5-7days for ready goods.

7.Q. Can you produce according to the samples?

A: Yes, we can produce by your samples or technical drawings. We can build the molds and fixtures.

8. Q. How do you make our business long-term and good relationship?

A:1. We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.