- Product Details

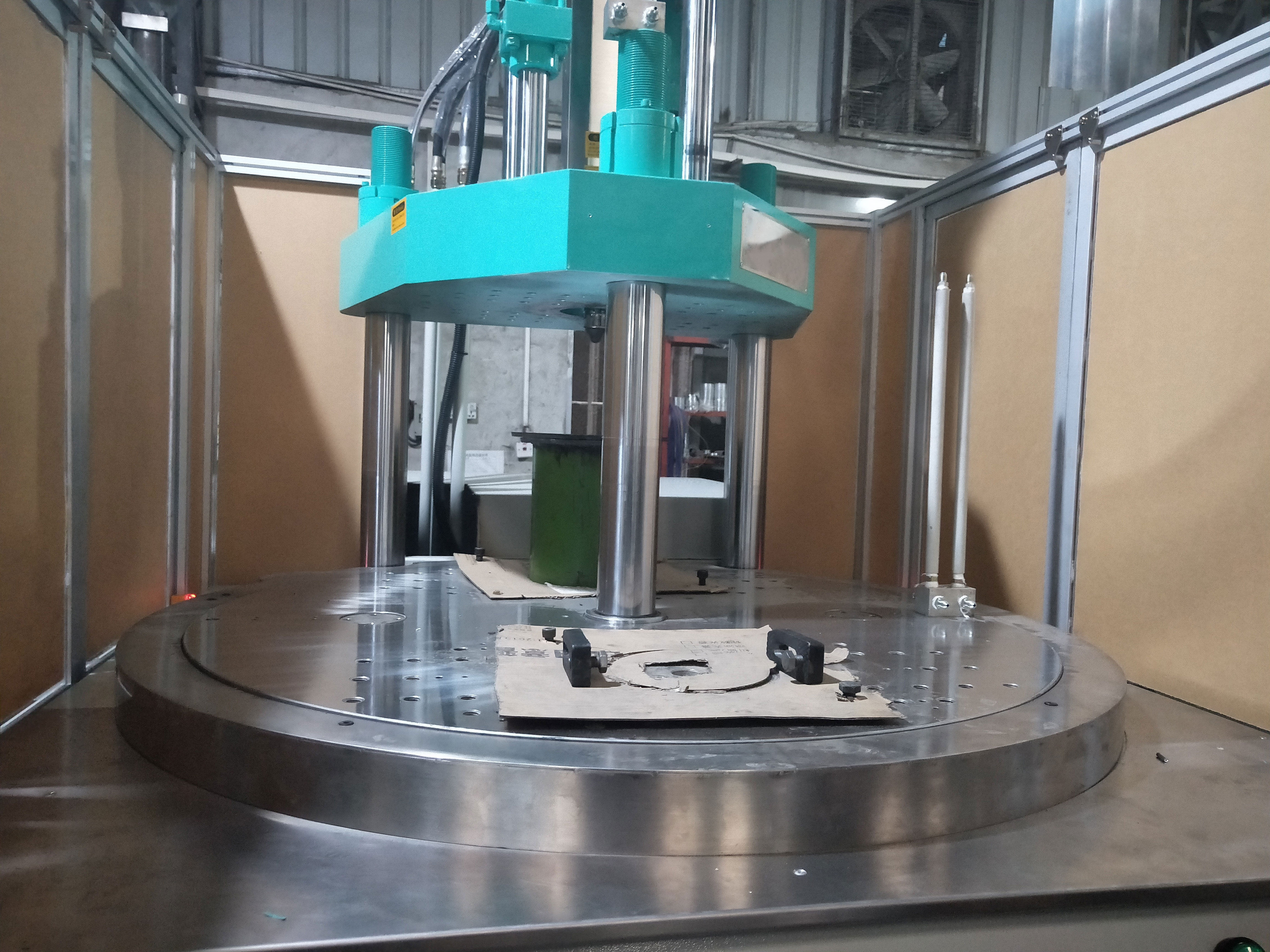

- {{item.text}}

Quick Details

-

Ejector Force(kN):

-

17.6 kN

-

Theoretical Shot Volume(cm³):

-

110 cm³

-

Injection Rate (g/s):

-

95 g/s

-

Injection Weight (g):

-

106 g

-

Screw Speed (rpm):

-

1 - 205 rpm

-

Screw diameter (mm):

-

35 mm

-

Screw L/D Ratio:

-

23

-

Distance between Tie Bars:

-

410*250mm

-

Weight (KG):

-

2400

-

Place of Origin:

-

Guangdong, China

-

Open Stroke(mm):

-

200 mm

-

Model Number:

-

CY-350ST-R-PP

-

Brand Name:

-

CanYang

-

Power (kW):

-

5.5 kW

-

Plastic Type:

-

Thermoplastic

-

Opening Stroke:

-

200mm

-

Injection Weight:

-

106g

-

Pump motor power:

-

5.5kw/7.5HP

-

Automatic:

-

Yes

-

Min. mold height:

-

500/200mm

-

Ejector force:

-

1.76Tons

-

Injection Rate:

-

115mm

-

Power(W):

-

9KW

-

Certification:

-

ce

Quick Details

-

Plasticizing Capacity(g/s):

-

69

-

Mold Height(mm):

-

200 - 600 mm

-

Ejector Stroke(mm):

-

35 mm

-

Ejector Force(kN):

-

17.6 kN

-

Theoretical Shot Volume(cm³):

-

110 cm³

-

Injection Rate (g/s):

-

95 g/s

-

Injection Weight (g):

-

106 g

-

Screw Speed (rpm):

-

1 - 205 rpm

-

Screw diameter (mm):

-

35 mm

-

Screw L/D Ratio:

-

23

-

Distance between Tie Bars:

-

410*250mm

-

Weight (KG):

-

2400

-

Place of Origin:

-

Guangdong, China

-

Open Stroke(mm):

-

200 mm

-

Model Number:

-

CY-350ST-R-PP

-

Brand Name:

-

CanYang

-

Power (kW):

-

5.5 kW

-

Plastic Type:

-

Thermoplastic

-

Opening Stroke:

-

200mm

-

Injection Weight:

-

106g

-

Pump motor power:

-

5.5kw/7.5HP

-

Automatic:

-

Yes

-

Min. mold height:

-

500/200mm

-

Ejector force:

-

1.76Tons

-

Injection Rate:

-

115mm

-

Power(W):

-

9KW

-

Certification:

-

ce

Product Description

Main Features

1) Simple structure in linear type, easy in installation and maintenance.

2) Adopting advanced world famous brand components in pneumatic parts, electric parts, and operation parts.

3) High-pressure double crank to control the die opening and closing.

4) Running in a high automatization and intellectualization, no pollution

5) Apply a linker to connect with the air conveyor, which can directly in line with filling machine.

Detailed Images

Product Image

Hot Searches