- Product Details

- {{item.text}}

Quick Details

-

Grinding Length(mm):

-

1000

-

Max. Weight of Workpiece(kg):

-

100

-

Wheel Size(mm):

-

500*50*203

-

Roundness(mm):

-

0.5

-

Place of Origin:

-

Shandong, China

-

Voltage:

-

Customization

-

Dimension(L*W*H):

-

460*250*220

-

Weight (KG):

-

6700

-

Product name:

-

CNC Cylindrical Grinder Machine

-

MOQ:

-

1Set

-

Payment:

-

L/C,T/T

-

Center taper:

-

4MT

-

Certificate:

-

CE / ISO

-

After warranty servide:

-

Online and video support

Quick Details

-

Grinding Diameter(Outer)(mm):

-

320

-

Grinding Diameter(Inner)(mm):

-

320

-

Surface Roughness(μm):

-

0.04

-

Grinding Length(mm):

-

1000

-

Max. Weight of Workpiece(kg):

-

100

-

Wheel Size(mm):

-

500*50*203

-

Roundness(mm):

-

0.5

-

Place of Origin:

-

Shandong, China

-

Voltage:

-

Customization

-

Dimension(L*W*H):

-

460*250*220

-

Weight (KG):

-

6700

-

Product name:

-

CNC Cylindrical Grinder Machine

-

MOQ:

-

1Set

-

Payment:

-

L/C,T/T

-

Center taper:

-

4MT

-

Certificate:

-

CE / ISO

-

After warranty servide:

-

Online and video support

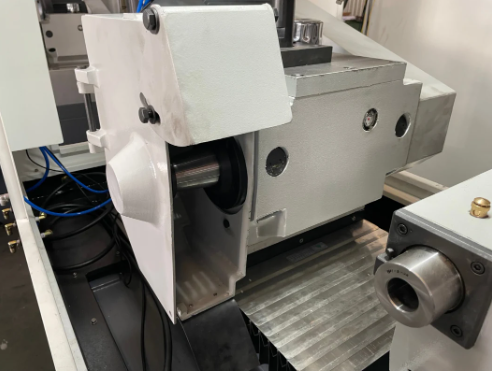

Product Display

|

Product name

|

MGK High Precision CNC Cylindrical Grinder

|

|

MOQ

|

1set

|

|

Payment

|

L/C,T/T

|

High Precision

The table(Z-axis) guide adopts open unloading Hydro-static guide structure, and the transverse feed(X-axis) adopts Swiss N/O linear guide strcture. It adopts high precision roller screw drive, zero clearance, low speed and no creep.

High Rigidity

The spindle of the grinding wheel adopts large taper, four oil wedge, automatic adjustable Hydro-dynamic pressure bearing, the workhead adopts Hydro-static spindle center-fixed grinding structure, the tailstock adopts dense bead sleeve or linear bearing structure, the whole machine has strong ridigity and high precision.

High Stability

The macine bed adopts double-layer structure(finite element analysis), the casting with special ratio is cast in one piece, and the combined surface is manually precision scraped, thus the thermal deforemation is stable and the accuracy is stable for a long time. Amony them, MGK1320 adopts mineral bed structure, no deformation, and the accuracy is more durable and stable.

M13 Series Grinding Feed In Type

M16 Series Grinding Wheel Oblique Feed

Specification

|

Description

|

Unit

|

MGK1320B

|

MGK1332

|

MGK1620

|

MGK1632

|

|

General Capacity

|

|

|

|

|

|

|

Distance between centers

|

mm

|

500,750

|

1000,1500

|

500,750

|

1000,1500

|

|

Center height

|

mm

|

135

|

180

|

135

|

180

|

|

Dia. Ground(O.D)

|

mm

|

8~200

|

8~320

|

8~200

|

8~320

|

|

Max. weight of workpiece

|

KG

|

50

|

100

|

50

|

100

|

|

Workhead

|

|

|

|

|

|

|

Center taper(MT)

|

MT

|

4

|

5

|

4

|

5

|

|

Spindle speed

|

r/min

|

50HZ:60~600

|

50HZ:35~350

|

50HZ:60~600

|

50HZ:35~350

|

|

Table: Max.swiveling angle of table

|

°

|

|

|

|

|

|

Clockwise

|

°

|

5 °(500)

3 °(750)

|

3°

|

5 °(500)

3 °(750)

|

3°

|

|

Anticlockwise

|

°

|

9 °(500)

6 °(750)

|

7°(1000)

6 °(1500)

|

9 °(500)

6 °(750)

|

7°(1000)

6°(1500)

|

|

Wheelhead

|

|

|

|

|

|

|

Max. dimension of wheel

|

mm

|

400*50*203

|

500*50*203

|

500*75*203

|

500*75*203

|

|

Wheel peripheral velocity

|

m/s

|

35

|

45

|

45

|

45

|

|

Min set unit

|

mm

|

0.0001

|

0.0001

|

0.0001

|

0.0001

|

|

Tailstock

|

|

|

|

|

|

|

Center taper

|

MT

|

4

|

4

|

4

|

4

|

|

Quill travel

|

mm

|

30

|

30

|

30

|

30

|

|

Electric system

|

|

|

|

|

|

|

CNC system

|

|

HNC-808DG, Siemens 808D, Fanuc01 MF

|

HNC-808DG, Siemens 808D, Fanuc01 MF

|

HNC-808DG, Siemens 808D, Fanuc01 MF

|

HNC-808DG, Siemens 808D, Fanuc01 MF

|

|

Wheelhead motor power

|

KW

|

5.5

|

7.5

|

7.5

|

7.5

|

|

Workhead motor power

|

KW

|

1.1

|

1.5

|

1.1

|

1.5

|

|

Machining accuracy

|

|

|

|

|

|

|

Roundness

|

µm

|

0.5

|

0.5

|

0.5

|

0.5

|

|

Cylindricity

|

µm

|

2(500), 3(750)

|

3

|

2(500), 3(750)

|

3

|

|

Roughness

|

µm

|

Ra0.04

|

Ra 0.04

|

Ra0.04

|

Ra0.04

|

|

Machine

|

|

|

|

|

|

|

Gross weight

|

KG

|

5.5(500) 6(750)

|

6.7(1000)

7.7(1500)

|

5.5(500)

6(750)

|

6.7(1000)

7.7(1500)

|

|

Packing dimension

|

cm

|

340*240*220(500)

400*240*220(750)

|

460*250*220(1000)

560*250*220(1500)

|

340*240*220(500)

400*240*220(750)

|

460*250*220(1000)

560*250*220(1500)

|

Corresponding to a variety of workpiece selection device

Related Product

Hot Searches