- Product Details

- {{item.text}}

Quick Details

-

Size:

-

4200mm 2550mm 1550mm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Tong Yang

-

Power:

-

1.1kw

-

Name:

-

laundry hotel sheets ironing machine

-

Heat:

-

Steam, electric

-

Ironing scope:

-

1.5m to 3.3m

-

Pressure:

-

0.4-0.6Mpa

-

Controller:

-

Automatic

-

Service:

-

Good

-

Manual book:

-

Provided

-

Installation:

-

Free-standing

-

Operation:

-

Easy

-

Used for:

-

Sheet ironing

Quick Details

-

Warranty:

-

1 Year

-

After-sales Service Provided:

-

Free spare parts

-

Weight:

-

1100kg

-

Size:

-

4200mm 2550mm 1550mm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Tong Yang

-

Power:

-

1.1kw

-

Name:

-

laundry hotel sheets ironing machine

-

Heat:

-

Steam, electric

-

Ironing scope:

-

1.5m to 3.3m

-

Pressure:

-

0.4-0.6Mpa

-

Controller:

-

Automatic

-

Service:

-

Good

-

Manual book:

-

Provided

-

Installation:

-

Free-standing

-

Operation:

-

Easy

-

Used for:

-

Sheet ironing

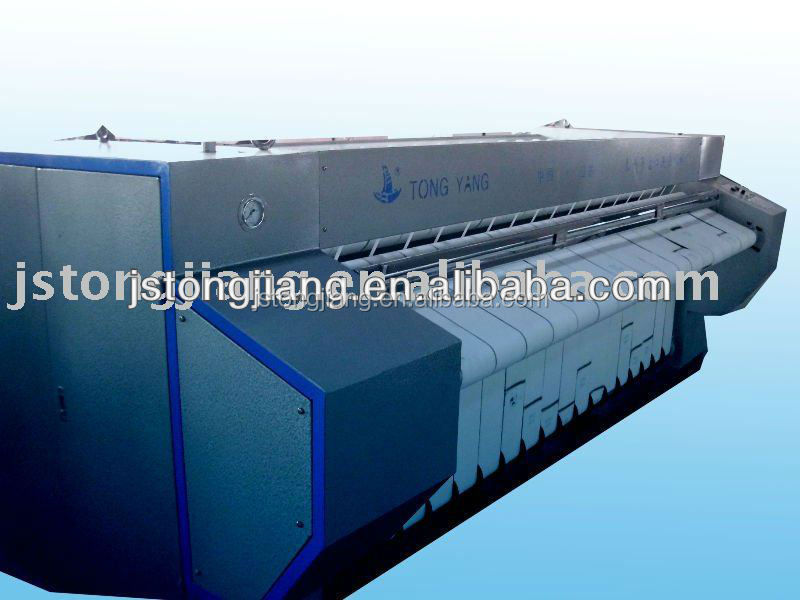

2.8m Double Rollers Professional Manuafacture laundry hotel sheets ironing machine,Tableclothes and Towels Ironing Machines

YPAI-YPAIII ironing machine:

Ironing machine, Industrial ironing machine, Commercial ironing machine, Automatic ironing machine, Laundry ironing machine, Ironing machine for bed sheets, Flatwork ironer, Flatwork ironing machine, Roll ironing machine, Industrial ironing machine for bed sheet, Marine ironing machine, Laundry flatwork ironer, industrial ironer.

Main features:

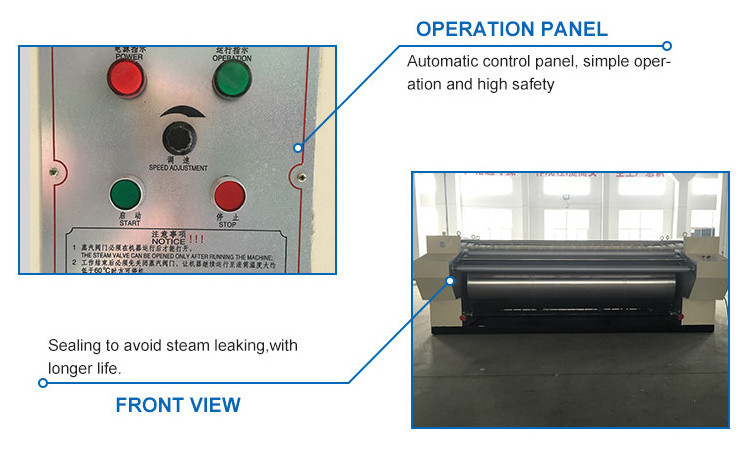

1. Automatic ironing machine,

horizontal

structure, easy to operate and high-quality ironing effect.

2.

Steam

or

electrical heating

.

3. Ironing for various of bed sheets, towel, tablecloth, curtain or liens which are usually used in

hotel,

restaurant, school, hospital, counterpane factory and laundry house, etc.

4. According to the fabric width, the roller length of industrial ironing machine can be 1800mm, 2500mm, 2800mm and 3000mm, also we can make the length less than 1800mm as per your requirements. And the roller can be single, double and three. Surely, the ironing speed of double rollers and three rollers ironing machine is quicker than that of single roller ironing machine

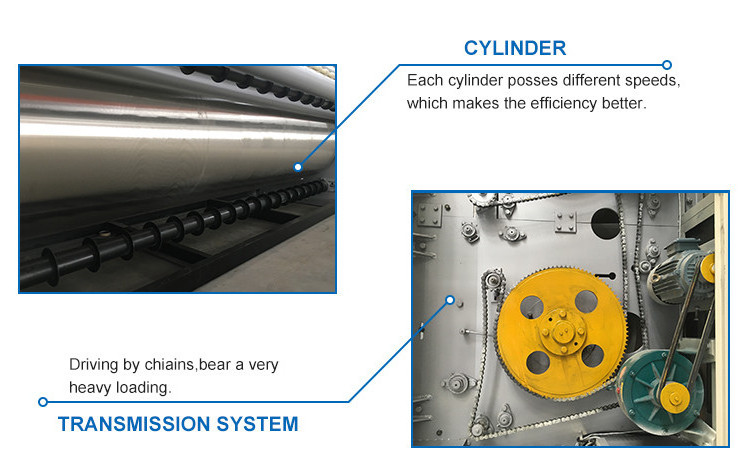

5. The precise structure of double chests, springs and heating proof felt ensure the rollers to keep enough electricity and spring cushion, which creates the surface well-touched. Unique lever balance pressure device and the cylinder pressure adjust system on both sides. Unique whirl steam flow heating system for the connecting plate improves the ironing result.

6.

Reliable and safe operation system

With a finger guard, once operator touches the plate the machine will stop immediately.

Anti-curliness device can prevent the fabrics curling in the chests.

With steam and compressed air control system, once the pressure is too low the system will alarm.

Many emergency stop button fixed on the ironer. Any buttoned pressed, the ironer will stop to run.

The pneumatic system can raise and lock up the rollers to prevent the fabrics and the proof felt damaged when the machine stops running in case of no power.

A big touch screen controller with interactive interface on the machine is easy for operator to program according to different requirements.

7.

High efficiency and Low energy consumption

The chests have a large angle heating surface, which can improve the heating efficiency.

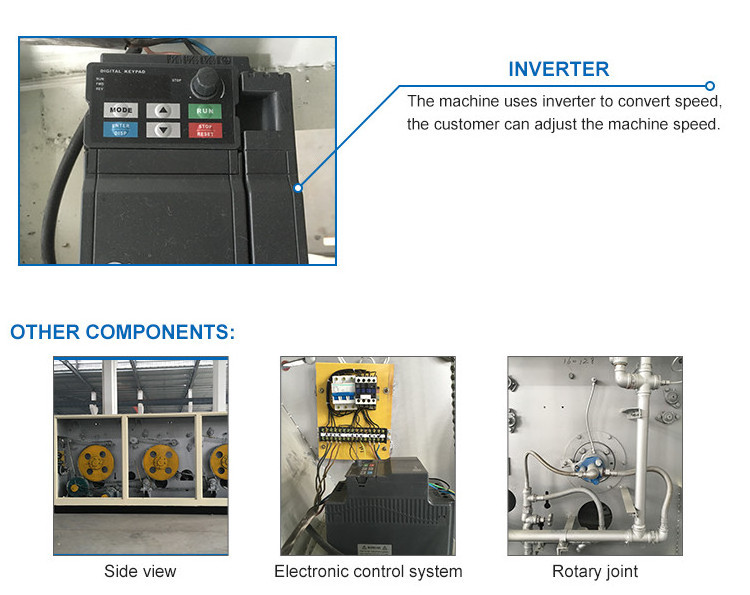

The ironer adopts a single drive motor which can save energy. The frequency converter system can adjust the ironing speed from 8~40 m/min with the change of temperature, type of fabrics, moisture, etc.

The chests adopt a unique heating chamber recycle system with many strips on double sides. Steam can flow in the chamber with high efficiency. In addition, the chests are covered by thermal insulators to reduce heat losses.

8. With

CE

and

ISO9001

certificates.

|

Type |

YPA I-1800 |

YPA I-2500 |

YPA I-2800 |

YPA II-2500 |

YPA II-2800 |

YPA II-3000 |

YPA III-3000 |

|

Tumbler specification(mm) |

Φ 800× 1800 |

Φ 800× 2500 |

Φ 800× 2800 |

Φ 800× 2500 |

Φ 800× 2800 |

Φ 800× 3000 |

Φ 800× 3000 |

|

Admission hole diameter(mm) |

25 |

25 |

25 |

28 |

32 |

40 |

60 |

|

Steam consumption |

50 |

70 |

80 |

110 |

150 |

180 |

300 |

|

Motor Power(Kw) |

0.75 |

0.75 |

0.75 |

1.5 |

1.5 |

1.5 |

2.2 |

|

Overall dimension(mm) |

2800× 1550× 1500 |

3500× 1550× 1500 |

3800× 1550× 1500 |

3550× 2500× 1500 |

3850× 2500× 1500 |

4050× 2500× 1500 |

4050× 3430× 1500 |

|

Drum quantity |

1 |

1 |

1 |

2 |

2 |

2 |

3 |

|

Weight (Kg) |

1011 |

1100 |

1136 |

1950 |

2200 |

2479 |

3460 |

Application show

|

We have advanced production

equipment including the CNC cut- ting machine,hydraulic plate ben- ding machine,and open back inc- linable press and soon on. |

We inspect our machine from the raw materials, the use of high-quality 304, 316 stainless steel. |

We will present the vulnerable parts for customers’ spare. |

|

Used the high quality

motor that special in washing laundry plant. |

We can ensure the monthly production capacity with more than two hundred staff,delivery the cargo to customers on time. |

Completed after-sales service system, if you need, we can arrange the installation team for you. |