The machine adopts hydraulic driver,is the latest products in our country. It can shearand cut punch a hole and cut moulds for square steel, steel strip channel, "工" shapesteel and angle steel and equip with empress anticipate.

- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V&380V

-

Dimension(L*W*H):

-

1640*730*1770

-

Motor Power (kW):

-

4kw

-

Weight (T):

-

1660

-

Machine Type:

-

Hydraulic Ironworker

-

Machinery Test Report:

-

Provided

-

Video outgoing-inspection:

-

Provided

-

Warranty of core components:

-

2 Years

-

Core Components:

-

pump

-

Color:

-

Customizable

-

Material:

-

Q235

-

Frame:

-

Frame Guide

-

Precision:

-

0.01mm

-

Control:

-

Hydrulic

Quick Details

-

Nominal Force (kN):

-

650

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

SXZG

-

Voltage:

-

220V&380V

-

Dimension(L*W*H):

-

1640*730*1770

-

Motor Power (kW):

-

4kw

-

Weight (T):

-

1660

-

Machine Type:

-

Hydraulic Ironworker

-

Machinery Test Report:

-

Provided

-

Video outgoing-inspection:

-

Provided

-

Warranty of core components:

-

2 Years

-

Core Components:

-

pump

-

Color:

-

Customizable

-

Material:

-

Q235

-

Frame:

-

Frame Guide

-

Precision:

-

0.01mm

-

Control:

-

Hydrulic

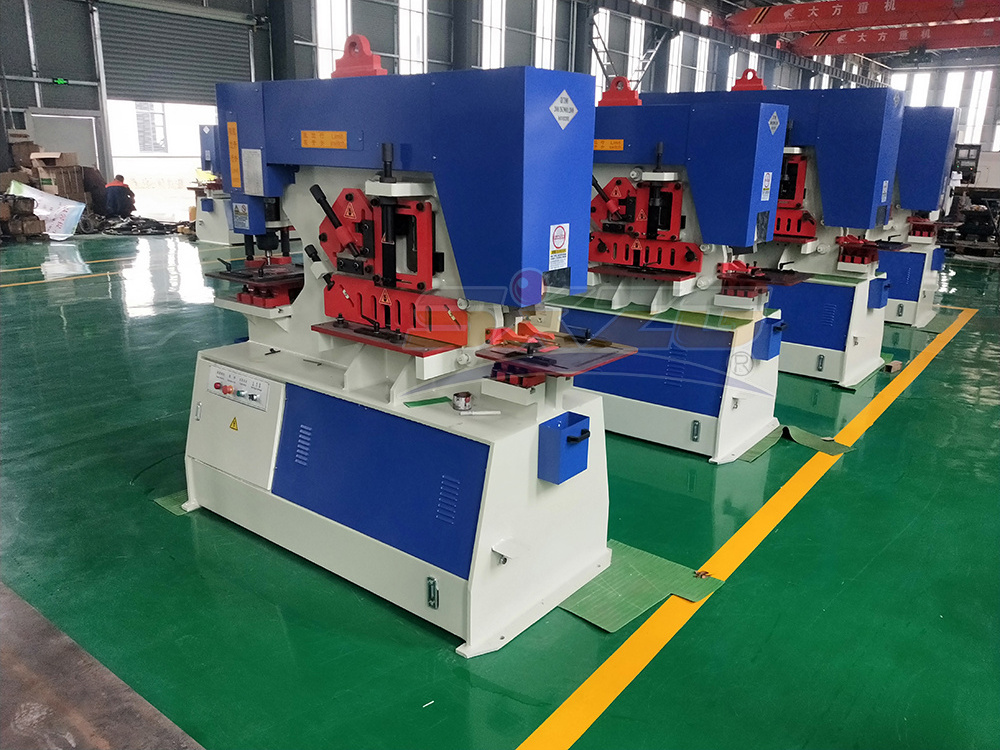

65 ton 45 ton q35y-40 q35-16 single cylinder cnc hydraulic ironworker machine

Ironworker Machine

Product Overview

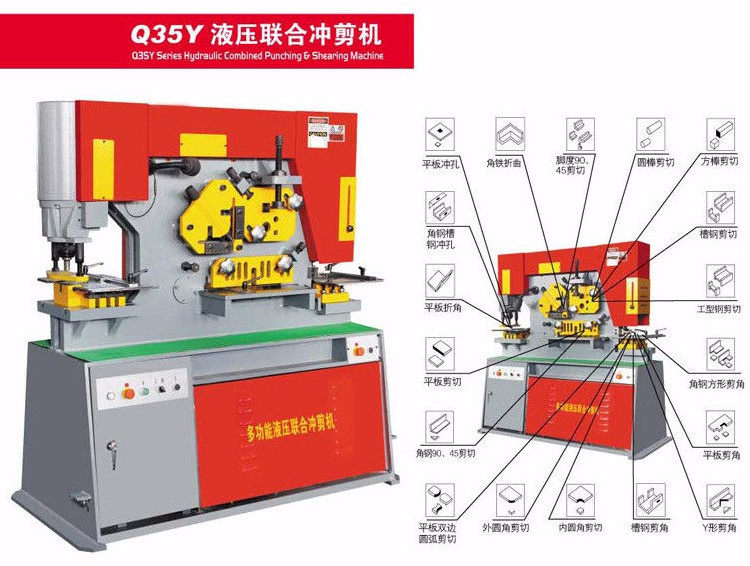

Q35Y hydraulic ironworker machine

industrial-grade combined punching and shearing machine featuring multiple functions, including: round hole, square hole, oblong hole punching; steel plate, flat bar, angle steel, C-channel, H-beam punching; steel plate bending; angle steel shearing, notching and bending; flat, round, square bar, C-channel, I-beam, T-bar shearing/cutting; angle bending and pipe notching.

FEATURES AT A GLANCE

The machine adopts hydraulic driver,is the latest products in our country. It can shearand cut punch a hole and cut moulds for square steel, steel strip channel, "工" shapesteel and angle steel and equip with empress anticipate.

Cutting bar/plate

Bender sheet(Optional)

Workpieces

PRODUCT SPECIFICATIONS

|

Type

|

Unit

|

Q35Y-16

|

Q35Y-20

|

Q35Y-25

|

Q35Y-30

|

Q35Y-40

|

Q35Y-50

|

|

Punching pressure

|

T

|

55

|

75

|

115

|

140

|

200

|

250

|

|

Max.cutting thickness

|

mm

|

16

|

20

|

25

|

30

|

40

|

50

|

|

Plate strength

|

N/mm2

|

W450

|

W450

|

W450

|

W450

|

W450

|

W450

|

|

Cutting angel

|

°

|

7°

|

8°

|

8°

|

8°

|

8°

|

8°

|

|

Slipper stroke

|

mm

|

80

|

80

|

80

|

80

|

100

|

100

|

|

Travel times

|

times/min

|

8

|

8

|

8

|

8

|

8

|

8

|

|

Throat depth

|

mm

|

300

|

355

|

400

|

600

|

700

|

800

|

|

Punching thickness

|

mm

|

16

|

20

|

25

|

26

|

35

|

35

|

|

Max.punching diameter

|

mm

|

25

|

30

|

35

|

38

|

40

|

45

|

|

Main motor Power

|

Kw

|

4

|

5.5

|

7.5

|

11

|

15

|

18.5

|

|

Dimension

(LxWxH)

|

mm

|

1640x730x1770

|

1860x800x1900

|

2350x960x2090

|

2680x1040x2300

|

2800x1100x2500

|

3000x1150x2600

|

|

Weight machine

|

kg

|

1600

|

2000

|

4800

|

6800

|

8600

|

12000

|

Product Design

PUNCHING IN IRONWORKER MACHINE

The machine punches from 30 mm diameters (8 mm thickness) to 57 mm diameters (22 mm thickness) very efficiently. Punches and dies are easily changeable. We provide special punches at short notice.

STEEL ROUND SQUARE BAR SHEARING

IN HYDRAULIC IRONWORKER

With this part of machine, squares from 25 mm to 55 mm and rounds from 30 mm diameters to 65 mm diameters can be cut very fast. By changing the blades you can also U-I or T sections. We provide special blades.

ANGLE SHEAR IN IRONWORKER

Here with the help of special blades you can cut several types of 90° – 45° angle sections efficiently.

NOTCHING

IN CNC HYDRAULIC IRONWORKER MACHINE

The machine comes with a rectangular notching tool which you can use for your notching works. We provide special notching tools for you notching works.

A MULTIFACETED TOOL

IN CNC HYDRAULIC IRONWORKER

These universal machines are supplied with standard tooling including X,Y gauging support tables at punch,shear, and notch stations. There are easily adjusted hold downs at all five work stations. Each work station is also equipped with specially designed hold downs to ensure safety while providing precision alignment and ease of use.

SIMILAR PRODUCTS

Hot Searches