- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

ORJ

-

Dimension(L*W*H):

-

3500*2300*2000mm

-

Weight (KG):

-

2500

-

Name:

-

Beverage can filling machine

-

Filling volume:

-

custom made for volume

-

Control:

-

PLC+ Touch Screen

-

Production capacity:

-

1000CPH to 36000CPH

-

Product:

-

soft drink/tea/juice/energy drink

-

Function:

-

Filling seaming

-

Processing:

-

Monobloc Machine

-

Bottle type:

-

Aluminum can/tin can

-

Advantage:

-

Running steady, easy operation, beautiful outlook

-

Filling Material:

-

POWER

Quick Details

-

Production Capacity:

-

2000

-

Voltage:

-

380V/410V/220V custom made

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

ORJ

-

Dimension(L*W*H):

-

3500*2300*2000mm

-

Weight (KG):

-

2500

-

Name:

-

Beverage can filling machine

-

Filling volume:

-

custom made for volume

-

Control:

-

PLC+ Touch Screen

-

Production capacity:

-

1000CPH to 36000CPH

-

Product:

-

soft drink/tea/juice/energy drink

-

Function:

-

Filling seaming

-

Processing:

-

Monobloc Machine

-

Bottle type:

-

Aluminum can/tin can

-

Advantage:

-

Running steady, easy operation, beautiful outlook

-

Filling Material:

-

POWER

Product Description

The canning machine is advanced filling and capping equipment, it’s designed on the basis of absorbing domestic and foreign advanced technology. It is mainly used in filling and capping carbonated beverages like soft drinks, cola, sparkling wine, juice hot filling etc. It has such advantages as advanced construction, stable working, convenient operation, and repair & maintenance, transducer control as well as high production efficiency. It is the ideal equipment for mid-scale & small-scale beverage factory.

Specification

Orange Beverage Machinery:

Bottle type: Aluminum Can/ Tin Can

Cap type: Lid

Production capacity: 1000 to 32000 cans per hour

Filling liquid: carbonated drink/soda water/ soft drink/ flavor drink /juice/ tea hot filling/ liquid with food

Bottle type: Aluminum Can/ Tin Can

Cap type: Lid

Production capacity: 1000 to 32000 cans per hour

Filling liquid: carbonated drink/soda water/ soft drink/ flavor drink /juice/ tea hot filling/ liquid with food

FULL PRODUCTION LINE OF CARBONATED DRINK FILLING LINE

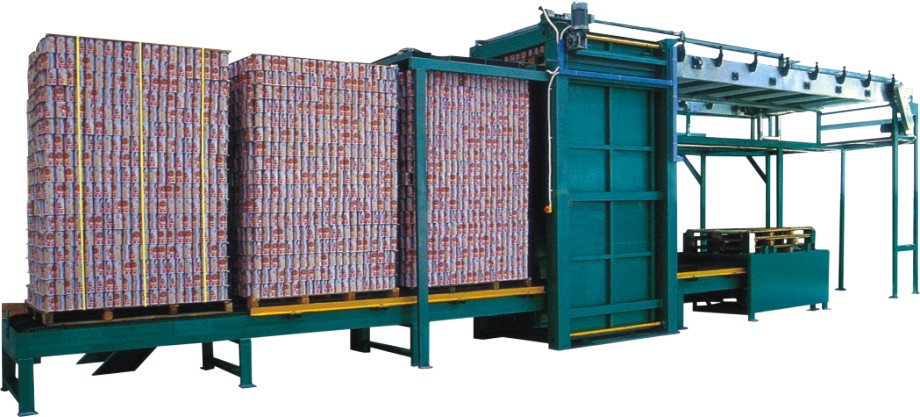

Depalletizer

Stacked cans after lifting pallets on a layer by layer push on the conveyor, and then by the

multi-column conveyor transport to Chute tank washing machine

multi-column conveyor transport to Chute tank washing machine

Can washer

Machine will turn over the empty cans, and directly spray rinsing inside of the can, then blower the

empty cans to clean

empty cans to clean

Can filling and sealing

Machine filling and sealing in one machine monoblock

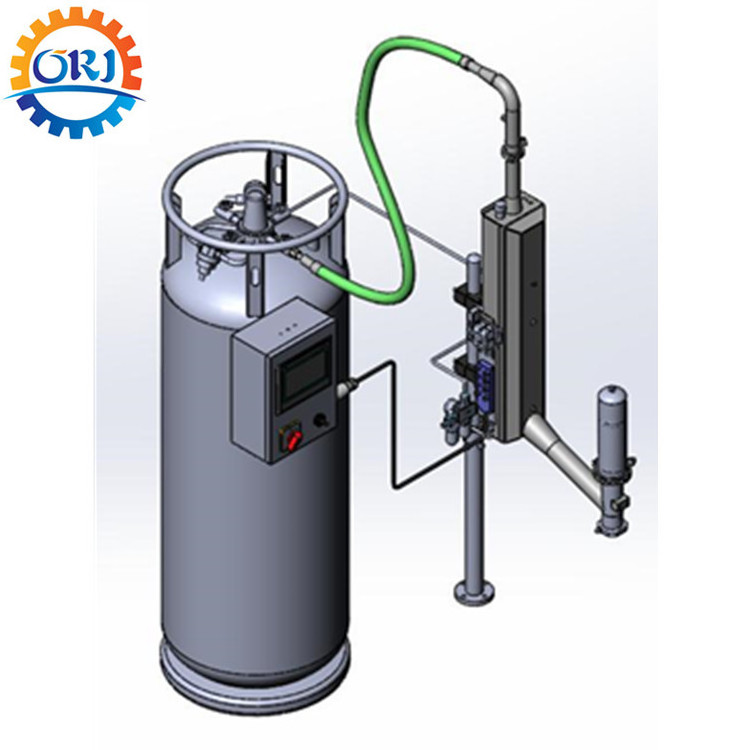

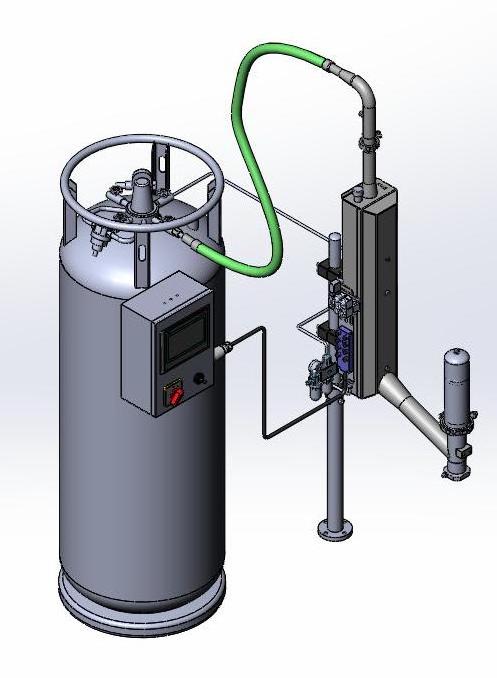

Nitrogen Doser

Liquid gas separator ensures that the liquid nitrogen is in a supercooled state and improves the purity of liquid phase, making the injection more precise and stable.

Date printer

Injet code printer

Laser Printer

Can packaging machine

Packaging the filler can

Shrink wrapping machine

Carton Packing Machine

ORANGE COULD DO FULL PRODUCTION LINE

1 Raw water tank + Raw water pump

2 Silica sand filter + Active carbon filter + Sodium ion exchanger + Precision filter + Security filter

3 Reverse Osmosis (one level)

4 UV sterilizer

5 Finished water tank + Pure water pump

2 Silica sand filter + Active carbon filter + Sodium ion exchanger + Precision filter + Security filter

3 Reverse Osmosis (one level)

4 UV sterilizer

5 Finished water tank + Pure water pump

BEVERAGE MIXING STATION

1 High-shear emulsifying tank + Plate heat exchanger

2 Mixing tank

3 UHT sterilizer + homogenizer machine + Buffer tank

4 Hot water system + Hot water tank

5 CIP cleaning system

2 Mixing tank

3 UHT sterilizer + homogenizer machine + Buffer tank

4 Hot water system + Hot water tank

5 CIP cleaning system

3) BEVERAGE FILLING AND PACKING STATION

WASHING FILLING CAPPING MACHINE -----LABELING MACHINE -----PACKAGING MACHINE

Packing & Delivery

* After complete the production, we will debug the production line, take photos, videos and send them to customers via mail orinstant tools

* After the commissioning, we will package the equipment by standard export package for shipment.

* We will contact with the forwarder company, in charge of booking vessel/airplane/train/ truck, arrange containers, buy

insurance, do all the DOCUMENTS, confirm the local customs clearance fee, and cooperate with the customer to clear the customs until the product arrive at the warehouse safely.

* After the commissioning, we will package the equipment by standard export package for shipment.

* We will contact with the forwarder company, in charge of booking vessel/airplane/train/ truck, arrange containers, buy

insurance, do all the DOCUMENTS, confirm the local customs clearance fee, and cooperate with the customer to clear the customs until the product arrive at the warehouse safely.

Company Profie

Zhangjiagang Orange Machinery Co., Ltd. located in Zhangjiagang City, Jiangsu Provice China, which is

near by Shanghai, is a professional manufacturer and after-service of beverage machinery including development, research, design, manufacturing, technical services and marketing.

Orange company has an existing factory of 5,000 square meters, and has more than 10 development and design engineers. Our main technical sources come from Italy, France, Germany, Switzerland, Russia and Southeast Asia. We learn from these technologies and incorporate our own design philosophy; we have produced high-starting, advanced technology, high - level automatic liquid filling equipment.

Orange company provides a variety of technical services to help users design with the layout of the equipment, answer the user process consultation, and provide the user personnel technical training and operation training etc.

Orange company can provide 3000-36000 bottles(PET or glass bottles) per hour of pure water, mineral water filling production line, 3000-36000 bottles(PET bottles) per hour carbonated beverage filling production line, 3000-36000 bottles(PET or glass bottles) per hour hot filling production line, 3000-18000 cans per hour cans production line , 3000-24000 bottles(PET or glass bottles) per hour wine, wine, liquor filling production line, 5000-40000 bottles(glass bottles) per hour beer filling production line, viscous body filling production line, 120-2000 barrels per hour 3-5 gallons bottled drinking water production line and Various ancillary products and equipment. We undertake all the turnkey projects.

Our main products: water treatment system, mixing tank, UHT sterilization system, CIP cleaning system, QHS beverage mixing system, XGF non-gas beverage filling equipment, DXGF pressure filling machine, RXGF hot filling machine, multi-function linear Liquid filling machine, LP Unscramble bottle machine, pasteurizer, warm bottle machines, blow molding machines, automatic packing machines, labeling machines etc

near by Shanghai, is a professional manufacturer and after-service of beverage machinery including development, research, design, manufacturing, technical services and marketing.

Orange company has an existing factory of 5,000 square meters, and has more than 10 development and design engineers. Our main technical sources come from Italy, France, Germany, Switzerland, Russia and Southeast Asia. We learn from these technologies and incorporate our own design philosophy; we have produced high-starting, advanced technology, high - level automatic liquid filling equipment.

Orange company provides a variety of technical services to help users design with the layout of the equipment, answer the user process consultation, and provide the user personnel technical training and operation training etc.

Orange company can provide 3000-36000 bottles(PET or glass bottles) per hour of pure water, mineral water filling production line, 3000-36000 bottles(PET bottles) per hour carbonated beverage filling production line, 3000-36000 bottles(PET or glass bottles) per hour hot filling production line, 3000-18000 cans per hour cans production line , 3000-24000 bottles(PET or glass bottles) per hour wine, wine, liquor filling production line, 5000-40000 bottles(glass bottles) per hour beer filling production line, viscous body filling production line, 120-2000 barrels per hour 3-5 gallons bottled drinking water production line and Various ancillary products and equipment. We undertake all the turnkey projects.

Our main products: water treatment system, mixing tank, UHT sterilization system, CIP cleaning system, QHS beverage mixing system, XGF non-gas beverage filling equipment, DXGF pressure filling machine, RXGF hot filling machine, multi-function linear Liquid filling machine, LP Unscramble bottle machine, pasteurizer, warm bottle machines, blow molding machines, automatic packing machines, labeling machines etc

FAQ

HOW TO FIND US?

* Search Alibaba, Google, Youtube and find suppliers and manufactrue and not traders

* Send Orange Machinery an request and tell your basic inquiry

* Orange Machine sales will reply you in short time and add instant chatting tool

WELCOME TO OUR FACTORY AT ANY TIME.

* If we can fullfill your request and you are interested in our products, you may pay a visit to Orange Machine.

* The meaning of visiting supplier, because seeing is believing, Orange Machinery with own manufacture and developed& research team, we can send you engineers and make sure your after sales service.

HOW TO GUARANTEE YOUR FUNDS TO BE SAFE AND DELIVERY TO BE ON TIME?

* Through Alibaba letter guarantee service, it will ensure the on time delivery and the quality of the equipment you want to

buy.

* By letter of credit, you can lock the delivery time easily.

* After the factory visit, You can ensure the facticity of our bank account. HOW TO ENSURE THE QUALITY.

* Before assembly, each component needs strictly control by inspecting personnel.

* Each assembly is in charged by a master who has working experience for more than 5 years.

* After all the equipment are completed, we will connect all the machines and run the full production line for at least 12 hours to ensure the stable running in customers' factory

AFTER-SALE SERVICE OF ORANGE MACHINERY.

* After complete the production, we will debug the production line, take photos, videos and send them to customers via mail or instant tools

* After the commissioning, we will package the equipment by standard export package for shipment.

* According to the customer's request, we can arrange our engineers to customers' factory to do the installation and training.

* Engineers, sales managers and after-sales service manager will form a after-sales team, online and off line, to follow the

customers' project.

* Search Alibaba, Google, Youtube and find suppliers and manufactrue and not traders

* Send Orange Machinery an request and tell your basic inquiry

* Orange Machine sales will reply you in short time and add instant chatting tool

WELCOME TO OUR FACTORY AT ANY TIME.

* If we can fullfill your request and you are interested in our products, you may pay a visit to Orange Machine.

* The meaning of visiting supplier, because seeing is believing, Orange Machinery with own manufacture and developed& research team, we can send you engineers and make sure your after sales service.

HOW TO GUARANTEE YOUR FUNDS TO BE SAFE AND DELIVERY TO BE ON TIME?

* Through Alibaba letter guarantee service, it will ensure the on time delivery and the quality of the equipment you want to

buy.

* By letter of credit, you can lock the delivery time easily.

* After the factory visit, You can ensure the facticity of our bank account. HOW TO ENSURE THE QUALITY.

* Before assembly, each component needs strictly control by inspecting personnel.

* Each assembly is in charged by a master who has working experience for more than 5 years.

* After all the equipment are completed, we will connect all the machines and run the full production line for at least 12 hours to ensure the stable running in customers' factory

AFTER-SALE SERVICE OF ORANGE MACHINERY.

* After complete the production, we will debug the production line, take photos, videos and send them to customers via mail or instant tools

* After the commissioning, we will package the equipment by standard export package for shipment.

* According to the customer's request, we can arrange our engineers to customers' factory to do the installation and training.

* Engineers, sales managers and after-sales service manager will form a after-sales team, online and off line, to follow the

customers' project.

Recommend Products

Hot Searches