- Product Details

- {{item.text}}

Quick Details

-

Application:

-

Outdoor

-

Design Style:

-

Industrial

-

Place of Origin:

-

China

-

Brand Name:

-

TD

-

Model Number:

-

geomembrane

-

Product Name:

-

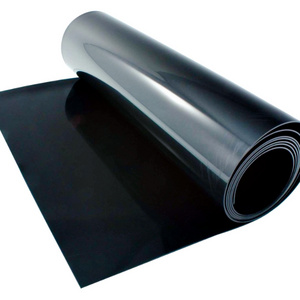

Pond Liner HDPE Geomembrane

-

Color:

-

Black White

-

Thickness:

-

0.1mm-4mm

-

Length:

-

50-200m

-

Width:

-

1m~8m

-

Certification:

-

ISO9001

-

Surface:

-

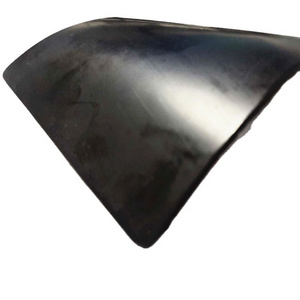

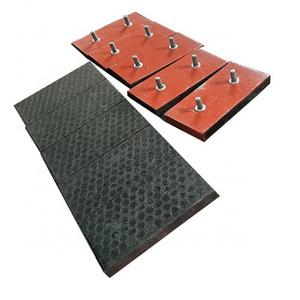

Smooth/Textured

-

Function:

-

Fish Pond Liner

-

OEM:

-

Yes

Quick Details

-

Warranty:

-

1 Year

-

After-sale Service:

-

Online technical support, Onsite Inspection

-

Project Solution Capability:

-

total solution for projects

-

Application:

-

Outdoor

-

Design Style:

-

Industrial

-

Place of Origin:

-

China

-

Brand Name:

-

TD

-

Model Number:

-

geomembrane

-

Product Name:

-

Pond Liner HDPE Geomembrane

-

Color:

-

Black White

-

Thickness:

-

0.1mm-4mm

-

Length:

-

50-200m

-

Width:

-

1m~8m

-

Certification:

-

ISO9001

-

Surface:

-

Smooth/Textured

-

Function:

-

Fish Pond Liner

-

OEM:

-

Yes

HDPE Geomembranes Ponds Dam liner

Product Description

HDPE Geomembrane pond liner

is a kind of smooth, high quality waterproof liner, which is made of specially formulated original polyethylene resin. This raw material is specially designed for flexible geomembrane applications.

The pond liner plastic sheeting contains about 97.5% polyethylene, 2.5% carbon black and traces of antioxidants and heat stabilizers. It does not use other additives, fillers or extenders.

Specification

|

NO

|

Test item

|

Technical data

|

|

|

|

|

|

|

|

|||||||

|

|

Thickness(mm)

|

0.50

|

0.75

|

1.00

|

1.25

|

1.50

|

2.00

|

2.50

|

3.00

|

|||||||

|

1

|

Density g/m2

|

≥0.94

|

≥0.94

|

≥0.94

|

≥0.94

|

≥0.94

|

≥0.94

|

≥0.94

|

≥0.94

|

|||||||

|

2

|

2 Tensile Yield Strength (MD&TD) (N/mm)

|

≥8

|

≥11

|

≥15

|

≥18

|

≥22

|

≥29

|

≥37

|

≥44

|

|||||||

|

3

|

Tensile Breaking Strength (MD&TD) (N/mm)

|

≥13

|

≥20

|

≥27

|

≥33

|

≥40

|

≥53

|

≥67

|

≥80

|

|||||||

|

4

|

Elongation at yield (MD&TD) (%)

|

≥12

|

≥12

|

≥12

|

≥12

|

≥12

|

≥12

|

≥12

|

≥12

|

|||||||

|

5

|

Elongation at break(MD&TD) (%)

|

≥700

|

≥700

|

≥700

|

≥700

|

≥700

|

≥700

|

≥700

|

≥700

|

|||||||

|

6

|

Tear Resistance (MD&TD) (N)

|

≥58

|

≥93

|

≥125

|

≥160

|

≥190

|

≥250

|

≥315

|

≥375

|

|||||||

|

7

|

Puncture Strength (N)

|

≥160

|

≥240

|

≥320

|

≥400

|

≥480

|

≥640

|

≥800

|

≥960

|

|||||||

|

8

|

Tensile load stress cracking (Constant load tensile method of incision) h

|

≥300

|

≥300

|

≥300

|

≥300

|

≥300

|

≥300

|

≥300

|

≥300

|

|||||||

|

9

|

Carbon Black Content (%)

|

2.0-3.0

|

2.0-3.0

|

2.0-3.0

|

2.0-3.0

|

2.0-3.0

|

2.0-3.0

|

2.0-3.0

|

2.0-3.0

|

|||||||

|

10

|

85°C heat aging (Atmospheric OIT retention after 90d) (%)

|

≥55

|

≥55

|

≥55

|

≥55

|

≥55

|

≥55

|

≥55

|

≥55

|

|||||||

|

11

|

UV protection (OIT retention rate after 1600 h uviolizing)

|

≥50

|

≥50

|

≥50

|

≥50

|

≥50

|

≥50

|

≥50

|

≥50

|

|||||||

|

12

|

Carbon black dispersion

|

In 10 datas, Grade 3≤1, Grade 4,5 are not allowed

|

|

|

|

|

|

|

|

|||||||

|

13

|

Oxidative Induction Time (min)

|

Atmospheric oxidative induction time≧ 100

|

|

|

|

|

|

|

|

|||||||

|

|

|

High pressure oxidative induction time≧ 400

|

|

|

|

|

|

|

|

|||||||

Production Process

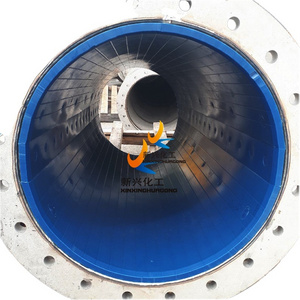

Project Case

Customer Reviews

Packing & Delivery

Hot Searches