Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Product name:

-

Stainless Spring Steel Standing Seam Metal Roof Clips

-

Material Capabilities:

-

304SS,301SS,316SS,201SS,1.4310,etc.

-

Finish:

-

Zinc Coating,Nickel,Chrome Plated,Color powder Coated

-

Tolerance:

-

0.02~0.1mm

-

Equipment:

-

Stamping Machine,Stamping Mould

-

Process:

-

Metal Stamping,Punching

-

Type:

-

Cold Stamping

-

Service:

-

Customize ODM OEM

-

Package:

-

Poly Bag + Carton

-

Samples:

-

Free samples after making mold

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

HC86

-

Model Number:

-

CN20230855

-

Product name:

-

Stainless Spring Steel Standing Seam Metal Roof Clips

-

Material Capabilities:

-

304SS,301SS,316SS,201SS,1.4310,etc.

-

Finish:

-

Zinc Coating,Nickel,Chrome Plated,Color powder Coated

-

Tolerance:

-

0.02~0.1mm

-

Equipment:

-

Stamping Machine,Stamping Mould

-

Process:

-

Metal Stamping,Punching

-

Type:

-

Cold Stamping

-

Service:

-

Customize ODM OEM

-

Package:

-

Poly Bag + Carton

-

Samples:

-

Free samples after making mold

Product Description

|

Products Item

|

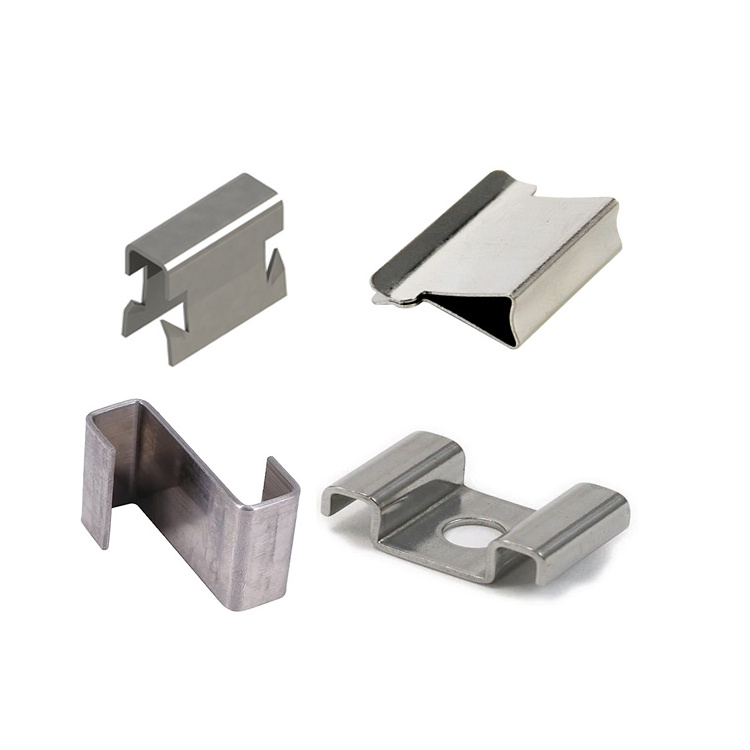

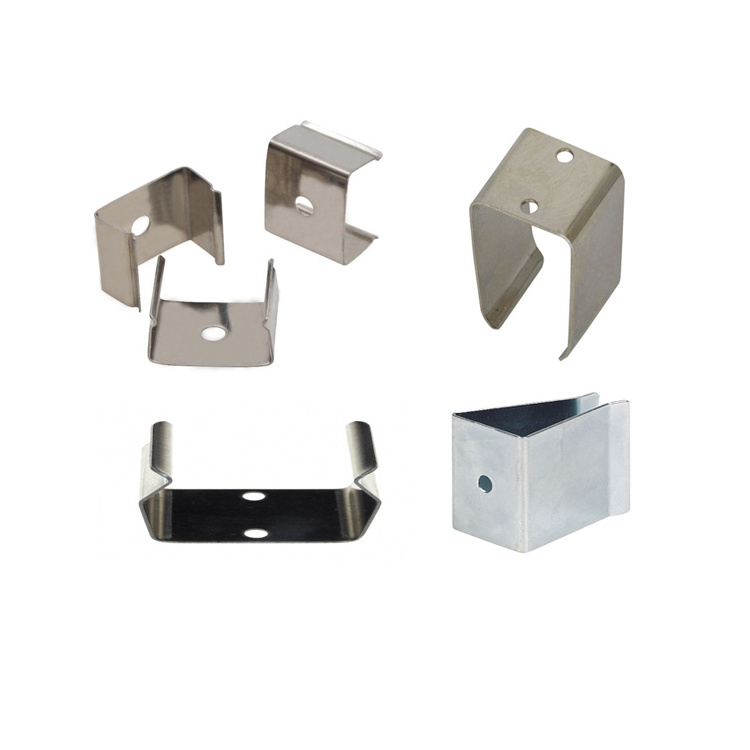

Custom Spring Fixed Clips Metal Stamping Bending Stainless Spring Steel Standing Seam Metal Roof Clips

|

|

Material Option

|

304ss,301ss,316ss,1.4310,stainless steel,Copper,Bass,etc.

|

|

Finish

|

Zin/nickel/gold/chorme/ silver/brass plated,Anodizing,Powder coated,electrophoresis,Painting,etc

|

|

Production time

|

10-15 working days

|

|

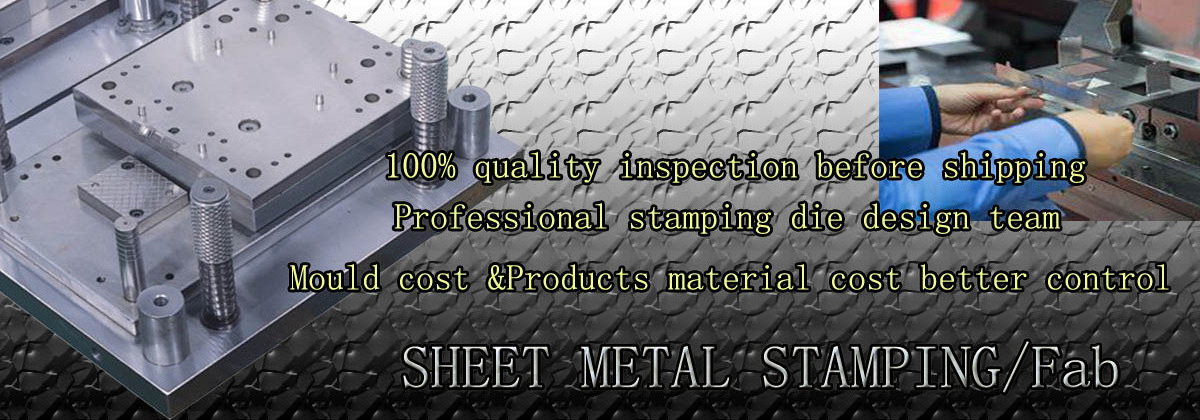

Quality Control

|

100% inspection before shipping,We have a professional team to control the quality. Experienced engineers, precision machines, CMM

and closed-loop QC system |

|

Samples

|

Free samples after making mould

|

Stamping process:

The stamping process of the material from deformation to separation can be divided into three steps:

1. Elastic deformation stage: Under the pressure of the punch, the material is deformed by elastic compression, bending and deep drawing.

2. Deformation stage: After the elastic deformation stage, the punch continues to press down, and the stress in the material reaches the yield strength, resulting in deformation.

3. Fracture (separation) stage: When the stress near the punch reaches the material failure stress, the material breaks.

Why Choose Us

One-Stop Service

Products Design

We can make the drawings according to your samples,To ptimized structural design and and combine multiple production processing to cost effective with high quality &fast delivery to meet your requirement

Cnc Machining

Custom made precision cnc machining milling/turning aluminum/stainless stee/steel/brass/pom/acrylic,etc

Sheet Metal Stamping

Sheet metal staamping parts,Sheet metal clips,Spring steel clips,Metal bracket,Battery contact,electrical

contact,Stamped wrenches,Metal strips,Washeres,Metal plate,Metal angle/conner,etc.

Sheet Metal Fabrication

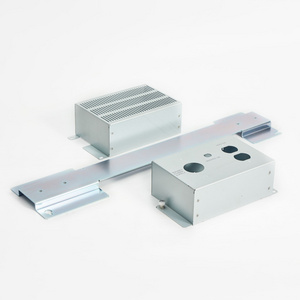

Custom made sheet metal fabrication stainless steel/aluminum/brass brackets&Plates,Metal angle,Cornner,Chassis shell,etc.

FAQ

Q:How long is your delivery time?

A:Samples:7-10working days;bulk production:10-15 working days.

Q:Do you provide samples, is it free or extra?

A:Yes,We’d like to provide samples before the bulk production,for the custom metal stamping samples,it can be free after making mold;

Q: What is your terms of payment ?

A: Payment<=5000 USD, 100% in advance. Payment>=5000 USD, 50% T/T in advance, 100% balance before shipment.

Q: Do you provide ODM/OEM service?

A: Yes,OEM / ODM is welcome, Please feel free to send us your drawing or samples

Q: If you make poor quality goods,will you refund our fund?

A: As a matter of fact,we wont take a chance to do poor quality products. Meanwhile,we manufacture goods quality products until your satisfaction.

Quality Control

100% inspection before shipping,

We have a professional team to control the quality. Experienced engineers, precision machines, CMM

and closed-loop QC system

and closed-loop QC system

Packing & Delivery

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

Hot Searches