●1)2-5 Axis Fully English Type CNC lathe controller

●2) 800x600 8.4 inch real color LCD displayer

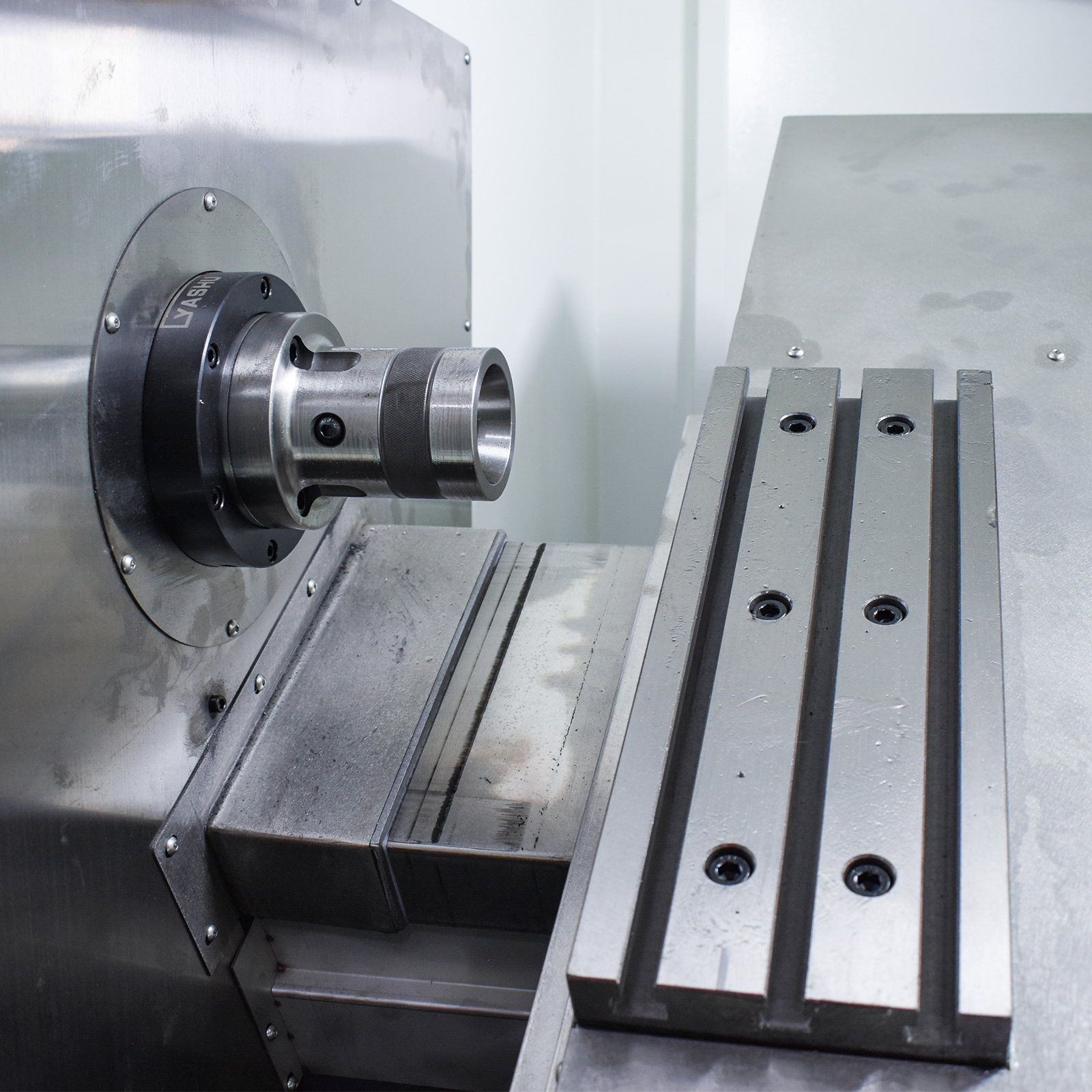

●3) Electric Turret & Binary code turret,Max: 99 pcs tools

●4) Support ATC , Macro function and PLC function

●5) Max speed is 60m/min, feeding speed is 24m/min

●6) Adapted servo spindle can realize spindle continous position,rigid tapping,rigid

screw processing

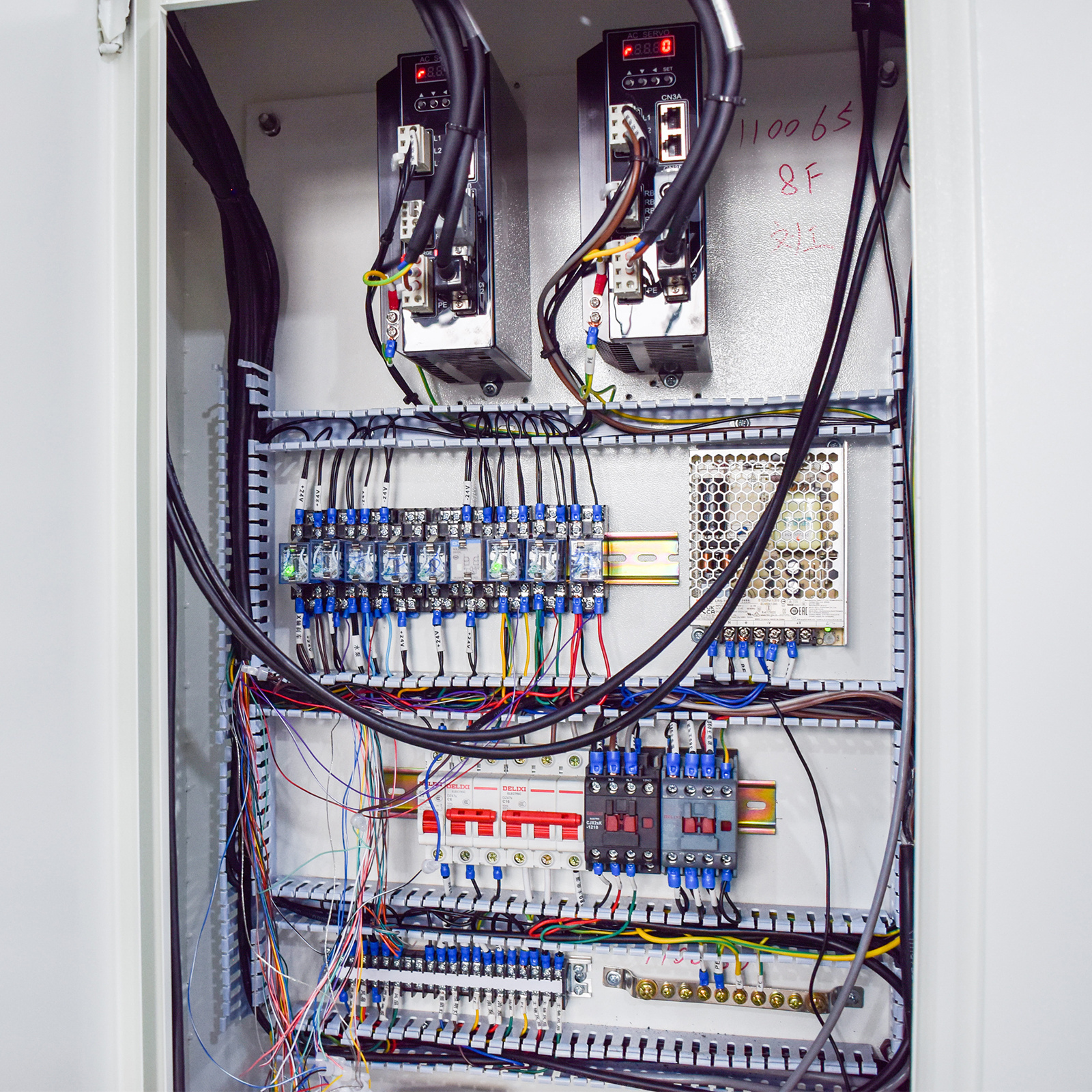

●7) High anti-jamming switch power( 100V-240VAC 50Hz/60Hz -> 24VDC)

●8)64MB Memory,56Mb user store room

●9) With USB interface,it supports file operation in flash disk,system configuration and

software upgrade

●10)Position Control Mode:Pulse+Direction/AB Phase,Dual Analog voltage output of

0~10V

●11)32 bits ARM microprocessor+FPGA Technology. .

●12)Basic I/O: 36X36 , can be edited freely

●13)cutter offset : C

●14)Installing dimension, electric interfaces, instruction system and operating windows

being compatible with those of GSK 980TDb Turning CNC System