- Product Details

- {{item.text}}

Quick Details

-

Brick size:

-

400*100*200 mm, 400*120*200 mm, 200*100*60 mm, 300*150*100 mm, 400*150*200 mm, 240*115*90 mm, 200*200*60 mm, 150*150*100 mm, Other, 400*200*200 mm, 230*220*115 mm

-

Place of Origin:

-

Guangxi, China

-

Brand Name:

-

HONGFA

-

Voltage:

-

380v/415v/440v as client requirement

-

Dimension(L*W*H):

-

5900*2200*2400 mm

-

Weight (KG):

-

7400 kg

-

Product Name:

-

HFB570A Block Making Machine

-

Exciting Force:

-

50 kn

-

Molding Form:

-

vibrating and pressure

-

Molding Cycle:

-

15-20 s

-

Total Power:

-

21.75 KW

-

Cotrol Method:

-

Full automatic PLC control

-

Pallet Size:

-

900*550 mm

-

Molding Method:

-

Automatic chargong,vibrating and pressing

-

Vibration frequency:

-

2800-5100 r/min

-

Rated pressure:

-

16MPa

Quick Details

-

Type:

-

Hollow Block Making Machine, Paving Block Making Machine, Interlock Block Making Machine, Curbstone Block Machine, Other, Autoclaved aerated concrete block (AAC)

-

Brick Raw Material:

-

concrete,cement,sand,crushed stone,fly ash,

-

Production Capacity (Pieces/8 hours):

-

4480 pcs/8hours, 2500 pcs/8hours, 3400 pcs/8hours, 1920 pcs/8hours, 5760 pcs/8hours, 1500 pcs/8hours, 1280 pcs/8hours, 3000 pcs/8hours, 12000 pcs/8hours, 3200 pcs/8hours, 2560 pcs/8hours, 1000 pcs/8hours

-

Brick size:

-

400*100*200 mm, 400*120*200 mm, 200*100*60 mm, 300*150*100 mm, 400*150*200 mm, 240*115*90 mm, 200*200*60 mm, 150*150*100 mm, Other, 400*200*200 mm, 230*220*115 mm

-

Place of Origin:

-

Guangxi, China

-

Brand Name:

-

HONGFA

-

Voltage:

-

380v/415v/440v as client requirement

-

Dimension(L*W*H):

-

5900*2200*2400 mm

-

Weight (KG):

-

7400 kg

-

Product Name:

-

HFB570A Block Making Machine

-

Exciting Force:

-

50 kn

-

Molding Form:

-

vibrating and pressure

-

Molding Cycle:

-

15-20 s

-

Total Power:

-

21.75 KW

-

Cotrol Method:

-

Full automatic PLC control

-

Pallet Size:

-

900*550 mm

-

Molding Method:

-

Automatic chargong,vibrating and pressing

-

Vibration frequency:

-

2800-5100 r/min

-

Rated pressure:

-

16MPa

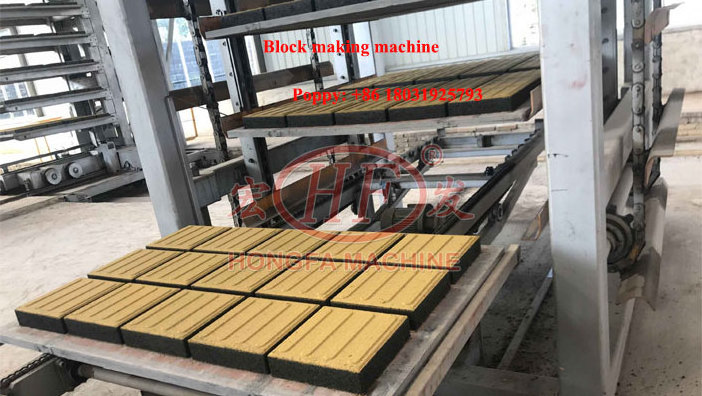

Automatic Concrete Cement Brick Machine Brick Making Machinery Block Making Machines For Small Businesses Brick Stacker

HFB570A Block Making Machine

Brief introduction:

1. Low frequency in feeding material, high frequency vibration. Platform vibrating works together with mould, So that the concrete can be fully fluidified and exhausted in two or three seconds to reach the high density.

2.The advanced technique of hydraulic-controlled proportion can handle the oil press and amount of the system freely,therefore ,different materials can be able to produce the high quality products.

3.All the procedures are operated by PLC and equipment with out and in date device to realize person-machine conversation. Control system also including the advanced safe logical system and fault diagnosis system.

The Advantages

The advantage of Molding Machine:

1- With Siemens PLC control system and Touch-operating Panel, Double Delta frequency converters, use less labor. Saving 25% energy compared to the same industry in the market.

2Hydraulic transmission,mechanical vibration, hydraulic pressing and forming are adopted

3- Adopting the advanced forced material-feeding & distributing device, More durable.

4- The computer is of fault diagnosis system . Warning signal is propitious to eliminate the fault.

The control system:

PLC intelligent control. Man-machine interface, control system equipped with complete logic control, production program, malfunction diagnosis system and remote control function. So it doesn't need a professional person but only need a simple trained one to the operator.

Concrete block interlocking paver brick machine concrete brick block moulding machine hollow block making machine price

The main Production Specification and Theoretical Productivity of HFB570A

| The main Production Specification and Theoretical Productivity | |||

| Item | Specification size (mm) | Quantity Per Mold | Molding Cycle |

| Hollow brick | 390*190*190 | 4pcs/mold | 15-20 s |

| Premeable brick | 200*100*60 | 14pcs/mold | 15-23 s |

| Standard brick | 240*115*53 | 24pcs/mold | 15-17 s |

Technical parameters of the model brick making machine

| Technical parameters of the model brick making machine | |

| Type | HFB570A |

| Exciting Force(KN) | 50 |

| Vibration Frequency (HZ) | 50 |

| Total Power(KW) | 21.75 |

| Moding Method | Automatic chargong, vibrating and pressing |

| Control Mode | Full Automatic PLC control |

| Moding Cycle(S) | 15-20 |

| Frame Dimension(mm) | 5900*2200*2400mm |

| Net Weight of Host Machine(T) | 5ton |

| Wood Pallet(mm) | 900*5500mm |

| Vibration Frequency | 2800-5100 r/min |

The Raw Materials of Block

|

Raw Materials : |

Crushed stone, sand, cement, dust and coal fly ash, cinder, slag, gangue, gravel, perlite and other industrial wastes. |

| Each country and region has different resources, we can customize the raw material mix according to the local resources of customers. | |

Product Application

Remarks: Different moulds produce different bricks. If there is no brick type you need in the drawing, please contact us and we can provide customized

Get the best price. Contact us now! Poppy: +8618031925793

We provide brick sample testing service for free, contact us now!

We provide pallet sample for free, contact us now!

Packing: Naked packing or stretch film packing or according to customers' requirements

Delivery time: Within 30 days after receipt of deposit and moulds confirmation from buyer

Lightweight Panel Production Line, AAC Block Production Line, Full Automatic Concrete Block Production Line, Artificial Quartz Plate Production Line, Concrete Pipe Machine, Concrete Tile Machine, Concrete pipe machine, Bidirectional Hydraulic Brick Maker, Mining Machinery, Concrete Batching plant, Stereo Parking Equipment, etc.

Pre-sales Service

(1) Professional suggestions (raw material matching, machine selection, the condition of building factory, feasibility analysis for panel machine production line).

(2) Device model choice (recommend the best machine according to the raw material, capacity and the size of panel).

(3) Welcome to visit our factory and production line anytime.

(4) Introduce the company file, product categories and production process.

After-sales Service

(1) Training how to install the machine, training how to use the machine.

(2) Engineers available to service machinery overseas.

(3) Recall clients regularly, get feedback in time, keep well communication with each other.

From the day our products sold, we will promise to do as follows:

(1) Provide corresponding technical solutions and site layout;

(2) Provide guidance equipment installation and operation for users.

(3) For each equipment ,we will train mainly operating personnel 5-10.

(4) 12 months guarantee, and provide lifelong technical support.

(5) Feedback within 24 hours after consulting.

(6) Build customers using and maintaining files as soon as dispatch machines;

(7) After finish debugging of equipment, users inspect and sign the acceptance certificate according to the situation of site service.