- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

baiseke

-

Model Number:

-

M1~M12 2-56~1/4-20

-

Equivalent standard:

-

ISO METRIC/Unit

-

Thread Type:

-

UNC, UNF

-

Quality control:

-

Range Inspection, Test report

-

Customized support:

-

OEM ODM OBM

-

Advantage:

-

One-stop Customized Service

-

MOQ:

-

Depends on the size

-

Lead Time:

-

2-5 days for standard parts

-

Certificate:

-

ISO, ROHS, REACH

Quick Details

-

Finish:

-

Plain

-

Measurement system:

-

Metric, Imperial (Inch)

-

Application:

-

Heavy Industry, Mining, Water Treatment, Healthcare, Retail Industry, Food & Beverage, General Industry, Oil & Gas, Automotive Industry

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

baiseke

-

Model Number:

-

M1~M12 2-56~1/4-20

-

Equivalent standard:

-

ISO METRIC/Unit

-

Thread Type:

-

UNC, UNF

-

Quality control:

-

Range Inspection, Test report

-

Customized support:

-

OEM ODM OBM

-

Advantage:

-

One-stop Customized Service

-

MOQ:

-

Depends on the size

-

Lead Time:

-

2-5 days for standard parts

-

Certificate:

-

ISO, ROHS, REACH

Products Description

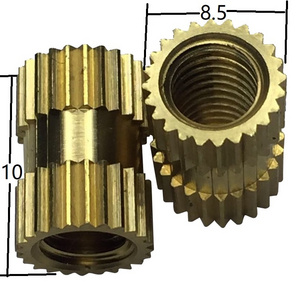

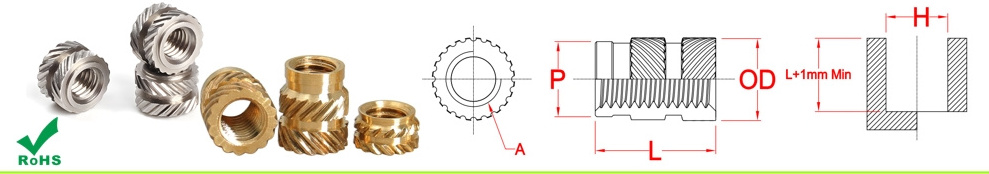

Heat-ultrasonic inserts for plastic

Install these inserts into plastic parts to create a secure base for fasteners. Also known as Chevron and headed inserts, they areoften used to strengthen mounting holes on brittle plastics, such as on 3D printed parts. Unlike plastic threads, which wear downwith repeated use, these threads hold their shape over a long life. Press inserts into straight holes that have been drilled,printed, or molded into plastic parts, then heat them with a soldering tip to melt the surrounding plastic. As the plastic cools,it fuses to the sharp, diagonal ridges around the inserts, which withstand torque and prevent the inserts from being pulled out.The interior is fully threaded, so you can access the threads from both sides of a through-hole.

Features

>Opposite helical knurl bands provide balanced high-torque and high pull-out performance

>

Ultrasonic / Heat staking threaded inserts

>

Designed for thermoplastic plastics (PPS

、

ABS、PP etc.)

Features

>Straight knurl and groove provides high tensile and

torsional

>Simple and easy to make for the structure

>Through hole/thread or blind hole / thread for choosing

|

◎Brass

inserts are stronger than aluminum and other brass alloys but not as strong as stainless steel inserts. They havegoodcorrosion resistance.

◎

Aluminum

inserts are 70% lighter than brass and stainless steel inserts, have good corrosion resistance, and are lead-free.Sincethey’re lead-free, they can be safely recycled.

◎Stainless steel

inserts are stronger than brass and aluminum inserts, have excellent corrosion resistance, and are

lead-free.Since they’re lead-free, they can be safely recycled. |

|

|

|

|

||||

SIMILAR PRODUCTS

Product packaging

bulk in cartons (25kg Max.)+ export Pallet or according to customer's requirement

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging serviceswill be provided.

Manufacturing Technique

We specialized in the manufacturing of kinds of fasteners, including bolts, screws, nuts, washers and other related parts, the specification covers GB standard, DIN standard, ANSI standard and JIS standard. Besides, Machining of non-standard items is also approved.

•Threaded and custom machined fasteners to your drawing specifications.

•Factory rapid prototyping and mass production.

•Quality assurance and testing to all specifications.

For major projects and large quantity or custom fastener requirements, we can set delivery schedules from blanket orders, managing the inventory in our warehouse space.

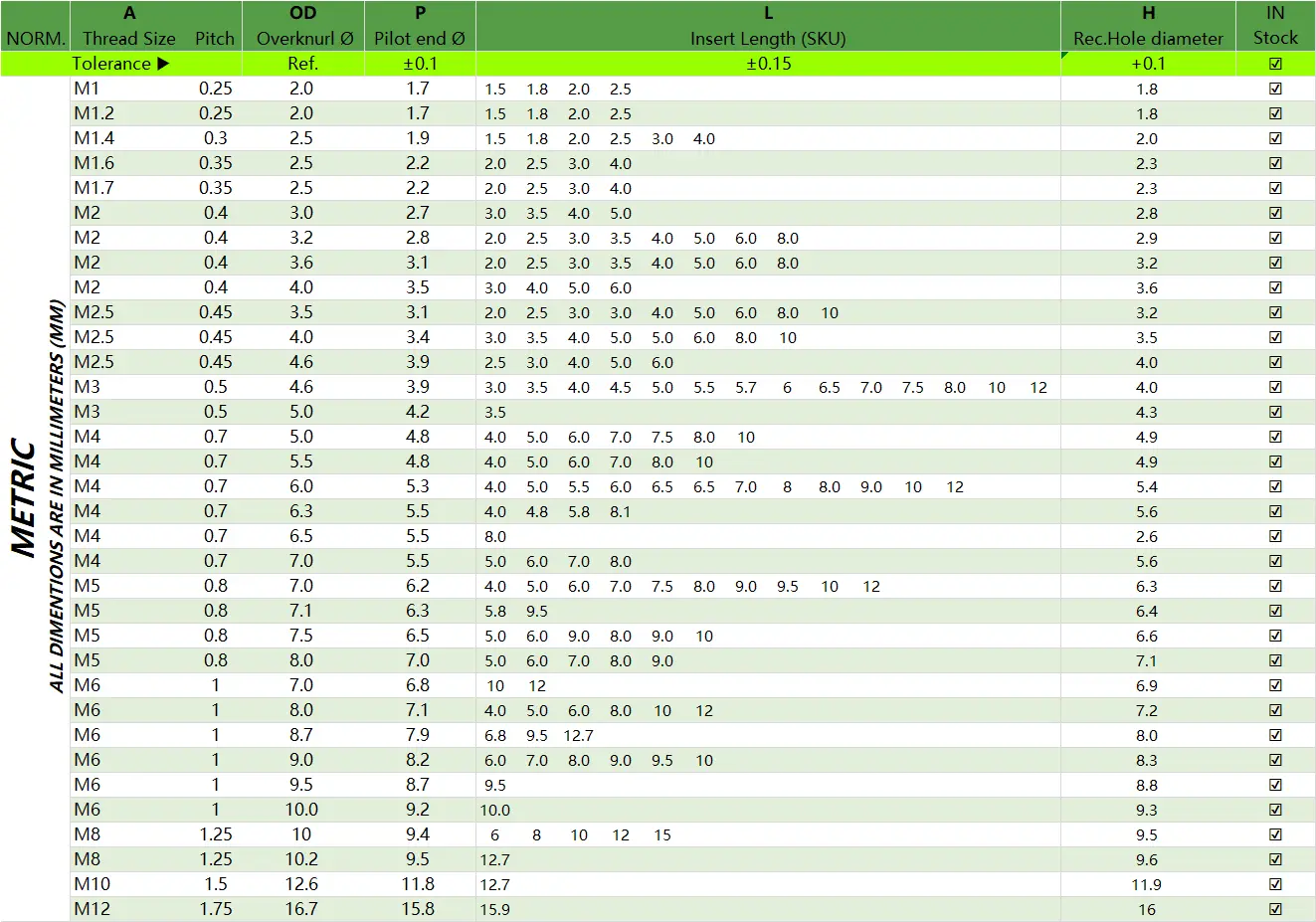

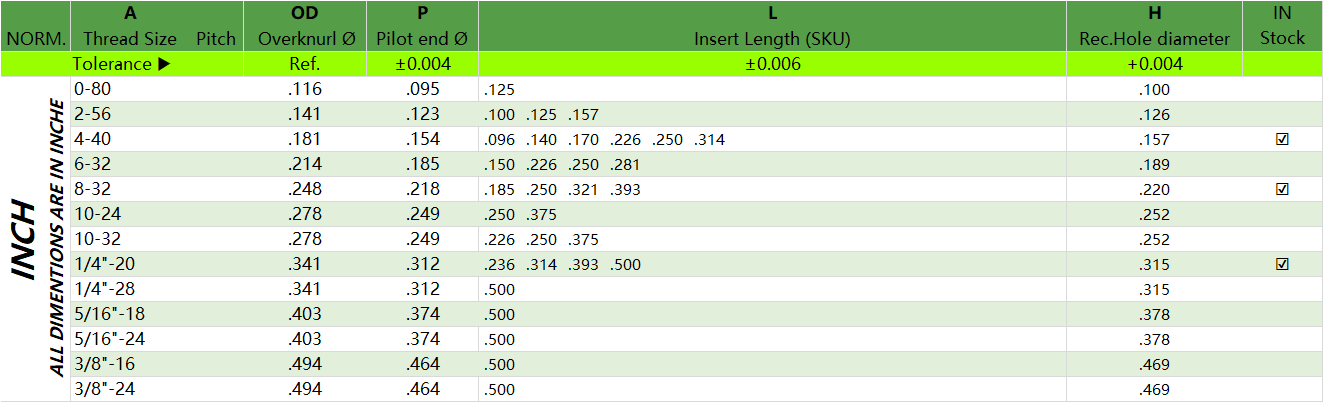

Specification

Why Choose Us

Focusing on creating value for customers

Our strategy is to benefit our customers first. Consistent pricing at a discount to competitors is applied across all our fastenerproduct lines. Our pricing structure is among the lowest in the fastener industry, and we deliver high levels of service. Thelatest technological fastening systems contribute to minimizing cost for our customers from quoting through delivery.

Certifications

We believe that only a perfect control process is an effective means to ensure quality

FAQ

Q :Can I get a sample?

A :Yes, we can provide free samples for stock items.

Q : How long for production?

A : We have many sizes of stock, we can ship out in 2-3 days for stock items.

Q: Other question please send to : info at baiseke com

A :Yes, we can provide free samples for stock items.

Q : How long for production?

A : We have many sizes of stock, we can ship out in 2-3 days for stock items.

Q: Other question please send to : info at baiseke com

Hot Searches