maintenance of the system

resistance

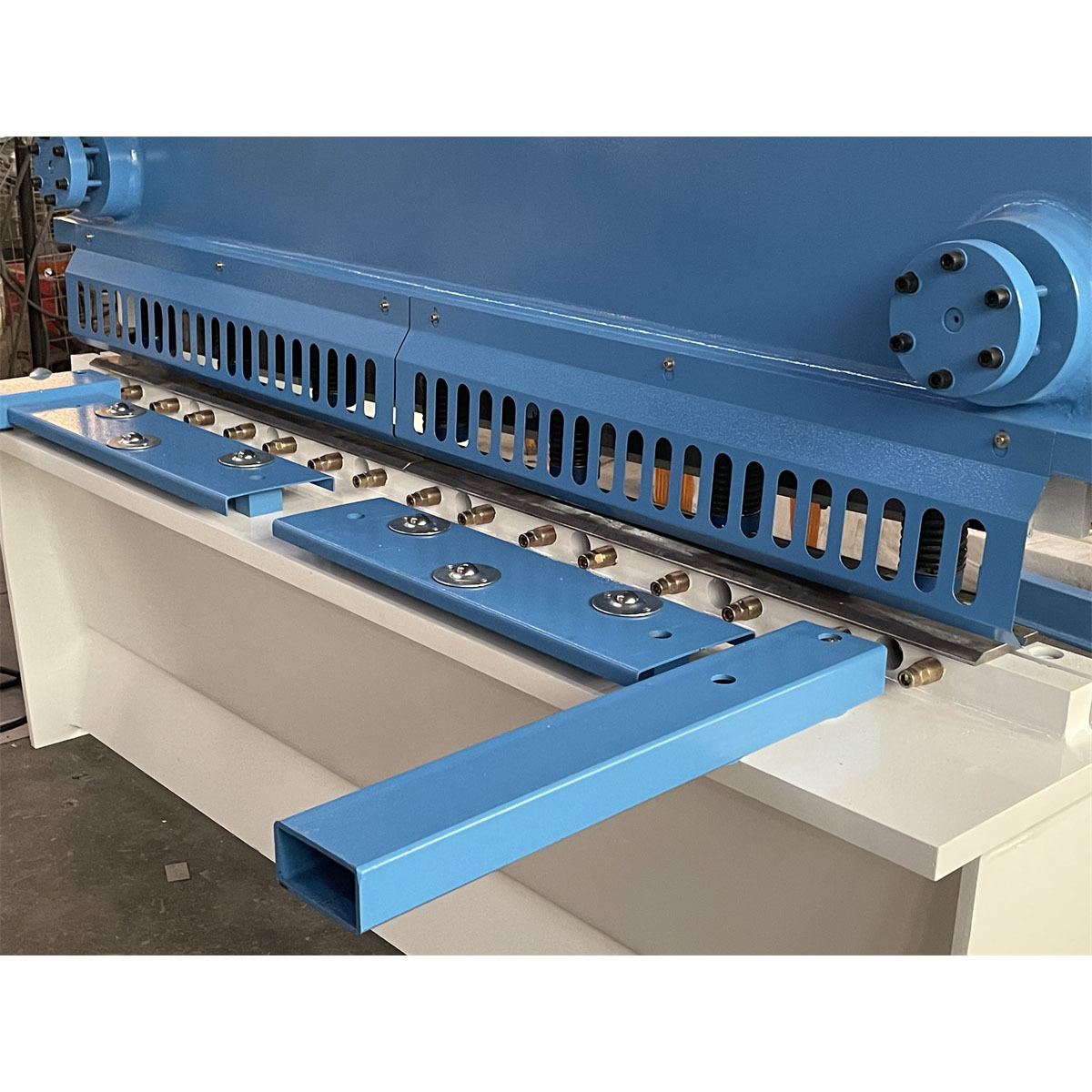

High quality guillotine steel cutting machine CNC hydraulic swing beam shears

Equipment:

1. Rapid and precise blade clearance adjustment by single handle on the side frame

2. Multi Edge Blades for cutting Aluminium, Mild Steel and Stainless Steel

3. Cutting Line Illumination and wire for shadow line cutting

4. Counter of Strokes, Cutting Length Adjustment

5. Hydraulic and Electrical overload protection

6. Squaring Arm and Front Support Arms

7. Estun E21S Controller

8. Germany Bosch-Rexroth Hydraulic

9. Telemecanique/SchneiderElectrics

10. Hydraulic and Electrical overload protection

11. Delta inverter with ball screw and polished rod with 0,05 mm accuracy.

12. Side guard is standard meeting CE regulations.

Better Cuttings:

1.Backgauge adjustment according to blade gap.

2.Backgauge retraction feature.

3.Sub-program and programming loop.

4.Sequence repeat function.

5.Auto cutting

6. Automatic clearance calculation depending on the material

|

Main Configuration

|

|

|

|

Main motor

|

Siemens,Germany

|

|

|

Electrics

|

Schneider, France

|

|

|

Hydraulic Valve

|

Rexroth,Germany

|

|

|

Oil pump

|

Sunny, USA

|

|

|

Tootswitch

|

Karcon, South Korea

|

|

|

Controller

|

Estun E21S

|

|

Pre-sales.

* Project design, performance introduction, technical agreement, contract signing, packaging

* Inquiry and consulting support.

* Sample testing support.

In-sales.

* We will provide you with the latest progress in the product assembly, packaging and transportation.

After-sale.

* We will provide free accessories for the damage to non - human parts.

* Training how to install the machine, training how to use the machine with video and so on

* And our technical staff can go abroad to provide technical guidance.

1. Are you the manufacture?Can we visit your factory?

We are manufacturer and we are located in Anhui,China.And we have our own design team for products design.

And welcome you visit our factory and check our machine qualtiy on spot,any question will be solved on spot at first time.

2.What's your main product and what is your main foreign market?

Our main products are press brake,shears machine,press,cutting machine,locking machine ,auto duct line and related products.

Our main foreign market are Asia, North America, Europe, Africa.

3. what are the advantages of your machines?And how can i believe the quality of your product?

The main configuration is to import quality products, and Professional product quality inspection team ensure machine in top-quality, precision and life.

For example,Germany Bosch-Rexroth Valve group,Germany Siemens Main Motor,Schneider Electrics system and so on.

Once tested as qualified .our machine would be sent out.So The quality of our product is stable and reliable.

4. And are you able to update the production process Information in time after placing our order?

After confirming your order ,we would keep you updated of production details of emails and photos.

5. Can we be your agent?

Yes,we are looking for Global agent we will help agent improve the market ,and supply all the service like machine technical problem or other after-sales problem, meanwhile ,you can get big discount and commission.

6. Payment terms?

T/T, L/C, Western Union, Paypal, Alibaba Secure Payment ect.

7.Are you provide product metal parts and provide us technical guidance?

Wearing parts,Disassembly tool(free) are what we could provide.And we can give you technical guidance.Our technical staff can go abroad to provide you with technical guidance.

8. How long is your warranty?

13 months free warranty, life-long maintenance.

9.Do you accept customer Logo and customized ?

we accept kinds of customized ,including logo and machine

.