- Product Details

- {{item.text}}

Quick Details

-

CERTIFICATE:

-

TEST REPORT/ISO9001

-

SAMPLE:

-

AVAILABLE

-

OEM:

-

AVAILABLE

-

Insulator fittings:

-

Ball, Socket, Tongue, Clevis, Eye,Pin, Tie,Flange etc.

-

Usage:

-

Station

-

Advantage:

-

Anti-pollution corrosion resistance,high mechanical strength

-

Rod diameter:

-

4mm-220mm Insulator epoxy resin rod

-

Dimension:

-

Customized

-

Product name:

-

Electrical transmission line polymer composite suspension insulator

-

Standard:

-

IEC62231

Quick Details

-

Brand Name:

-

TID POWER

-

Place of Origin:

-

Shaanxi, China

-

Model Number:

-

FZSW110

-

CERTIFICATE:

-

TEST REPORT/ISO9001

-

SAMPLE:

-

AVAILABLE

-

OEM:

-

AVAILABLE

-

Insulator fittings:

-

Ball, Socket, Tongue, Clevis, Eye,Pin, Tie,Flange etc.

-

Usage:

-

Station

-

Advantage:

-

Anti-pollution corrosion resistance,high mechanical strength

-

Rod diameter:

-

4mm-220mm Insulator epoxy resin rod

-

Dimension:

-

Customized

-

Product name:

-

Electrical transmission line polymer composite suspension insulator

-

Standard:

-

IEC62231

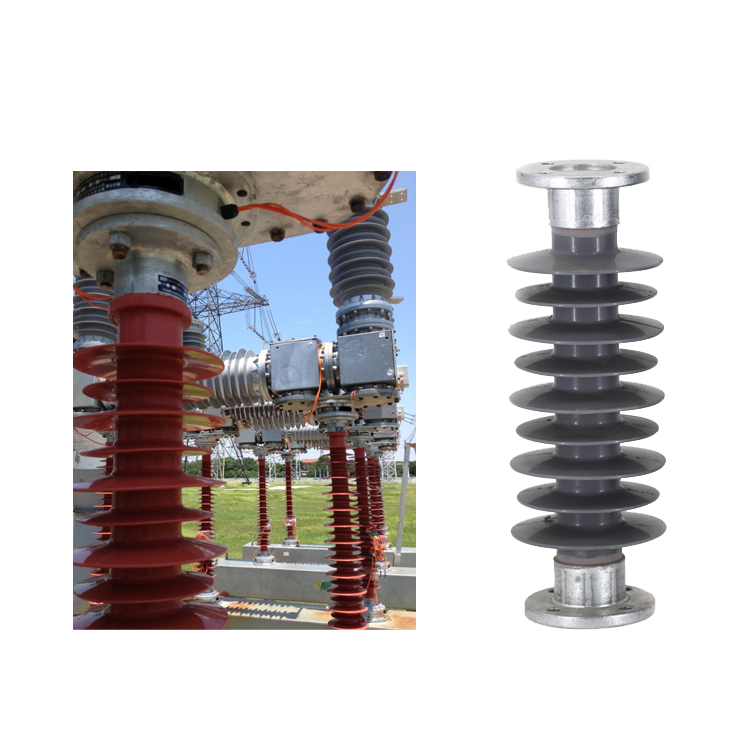

Composite station post insulators (110 - 800kV)

Composite station post insulators can directly replace porcelain insulators. Composite insulators with silicone rubber insulation possess unique properties and are installed all over the world.

We offer a wide range of insulators, and together with our flexible production method

can deliver composite insulators that will meet your requirements.

Why TID power products?

- More than 25 years of experience in manufacturing composite insulators

- Explosion-proof for maximum safety

- Non-brittle material with reduced risk of damage during handling

- Leakage current control through hydrophobicity

- Excellent insulation for reduced creepage

- Flashover resistance

- Outstanding seismic performance for safety and reliability

- Low weight for cost savings

- Maintenance-free and outstanding pollution performance

- UV stability

- For high-voltage applications and substations

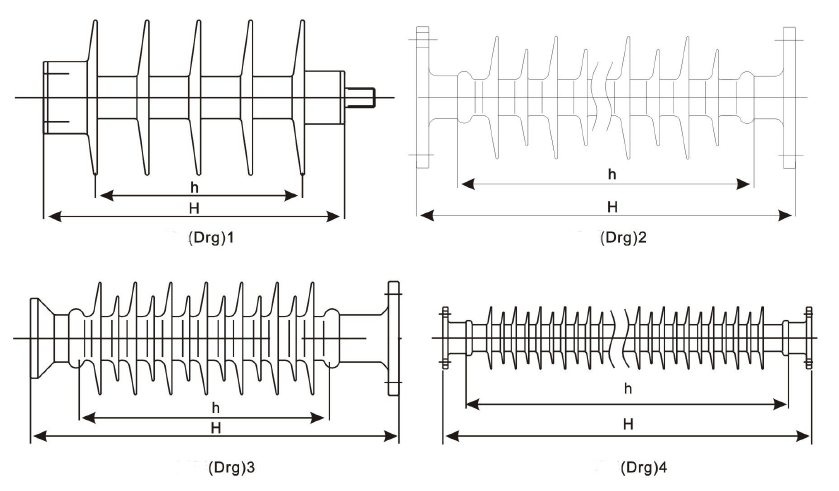

|

Specified Voltage (KV) |

SBL (KN) |

Section Length H(mm) |

Min Arcing Distance h(mm) |

Min Nominal Creepage Distance L(mm) |

Lightning Impulse Withstand Voltage (kV) |

Power Frequency withstand voltage (kV) |

P.F.withstand voltagemin wet(kV) |

|

|

FZSW-110/8.0 |

110 |

8 |

1220±5 |

1060 |

3200 |

550 |

320 |

230 |

|

FZSW-132/10 |

132 |

10 |

1750±5 |

1630 |

8000 |

890 |

510 |

400 |

|

FZSW-132/12 |

132 |

12 |

1300±5 |

1070 |

5800 |

650 |

420 |

320 |

|

FZSW-132/12 |

132 |

12 |

1700±5 |

1340 |

5800 |

700 |

450 |

340 |

|

FZSW-220/6.0 |

220 |

10 |

2300±5 |

2174 |

9500 |

1250 |

710 |

550 |

Double Seal End Part Design Good Hydrophobicity Performance