- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

350

-

Voltage:

-

380 V

-

Current:

-

19500 A

-

Rated Capacity:

-

50 KVA

-

Rated Duty Cycle:

-

25 %

-

Dimensions:

-

400*800*900 mm

-

Use:

-

seam welding of metal material.

-

Name:

-

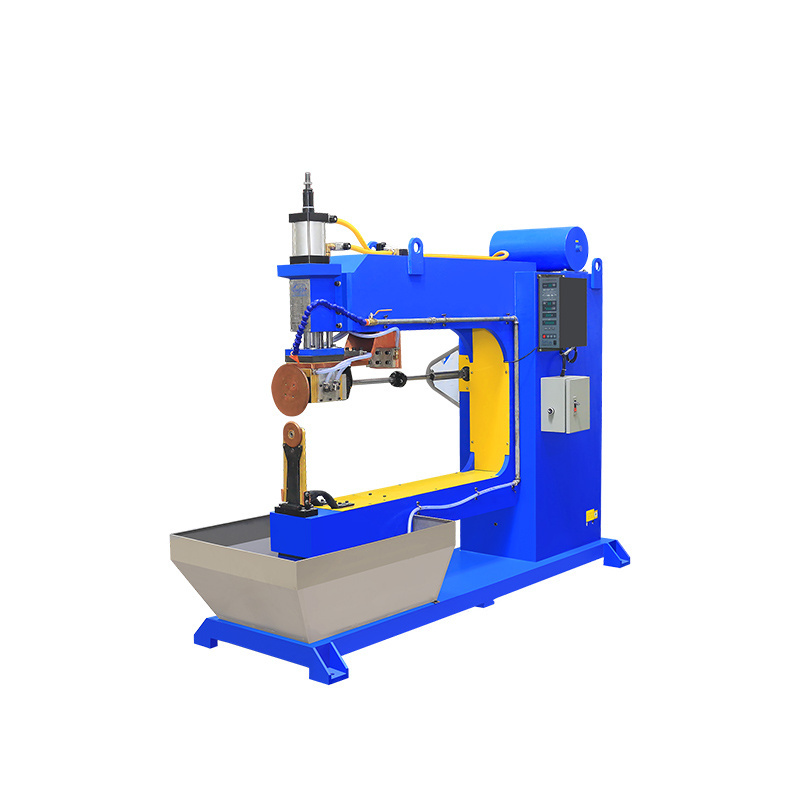

Straight Seam Circle Tube Welding Machine

-

Input Voltage:

-

380 V

-

minimum welding thickness:

-

0.2 mm

-

welding thickness:

-

3.0-8.0 mm

-

workpiece minimum diameter:

-

300 mm

-

Motor:

-

DC servo motor

-

Service life:

-

8-10 years

-

welding gun movement rate:

-

0.5m/sec

-

Forming Time:

-

8 min/pc

-

Package:

-

Wooden Sealed Packing

Quick Details

-

Marketing Type:

-

Hot Product

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

HAWSHI

-

Weight (KG):

-

350

-

Voltage:

-

380 V

-

Current:

-

19500 A

-

Rated Capacity:

-

50 KVA

-

Rated Duty Cycle:

-

25 %

-

Dimensions:

-

400*800*900 mm

-

Use:

-

seam welding of metal material.

-

Name:

-

Straight Seam Circle Tube Welding Machine

-

Input Voltage:

-

380 V

-

minimum welding thickness:

-

0.2 mm

-

welding thickness:

-

3.0-8.0 mm

-

workpiece minimum diameter:

-

300 mm

-

Motor:

-

DC servo motor

-

Service life:

-

8-10 years

-

welding gun movement rate:

-

0.5m/sec

-

Forming Time:

-

8 min/pc

-

Package:

-

Wooden Sealed Packing

Product Description

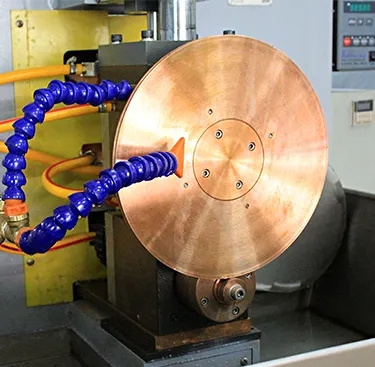

Factory longitudinal seam welding machine

Product Description

1. Double drive design, rotating conductive shaft with silver tile device. The mechanical failure caused by transmission friction can be effectively improved and the welding efficiency can be greatly improved. The equipped grinding wheel can be used to grind the welding wheel automatically, which can ensure the welding consistency. The welding process will not cause the breakdown of the welding piece due to the pause, and the welding speed does not change due to the wear of the welding wheel. The working process of high quality leakage proof circular seam welding machine is automatic, with high degree of automation and productivity. Suitable for high production operation.

2. Seam welding machine is to use the electrode wheel to pressurize the welding parts while the electrification, using the contact resistance between the electrodes to generate the joule heat instant melting metal under the pulse action to achieve the goal of seam welding. No need to add any solder, high efficiency and low cost. Easy to achieve automatic welding.

3. Welding speed does not change due to wear of the welding wheel. The working process of welding machine is automatic, with high degree of automation and productivity.

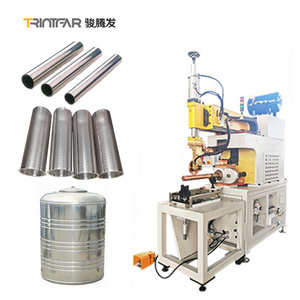

4. It is the most ideal equipment in the field of solar water heater, water tank, oil tank, pipe, gas storage tank, instrument case and so on.

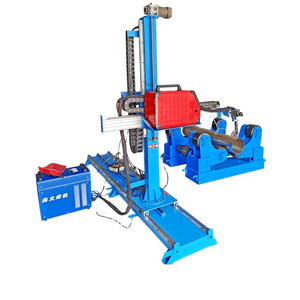

Product Application

Longitudinal rolling seam welding machine for fuel tank is widely used in automobile, damper of motorcycle, detector of temperature controller, nickel strap of battery, oil heater, power capacitor, sieve iron basket, water pump manufacturing, tin making, coopery industry, etc.

Intelligent welding control system

Intelligent Touch Screen Controller

Input and read welding parameters.

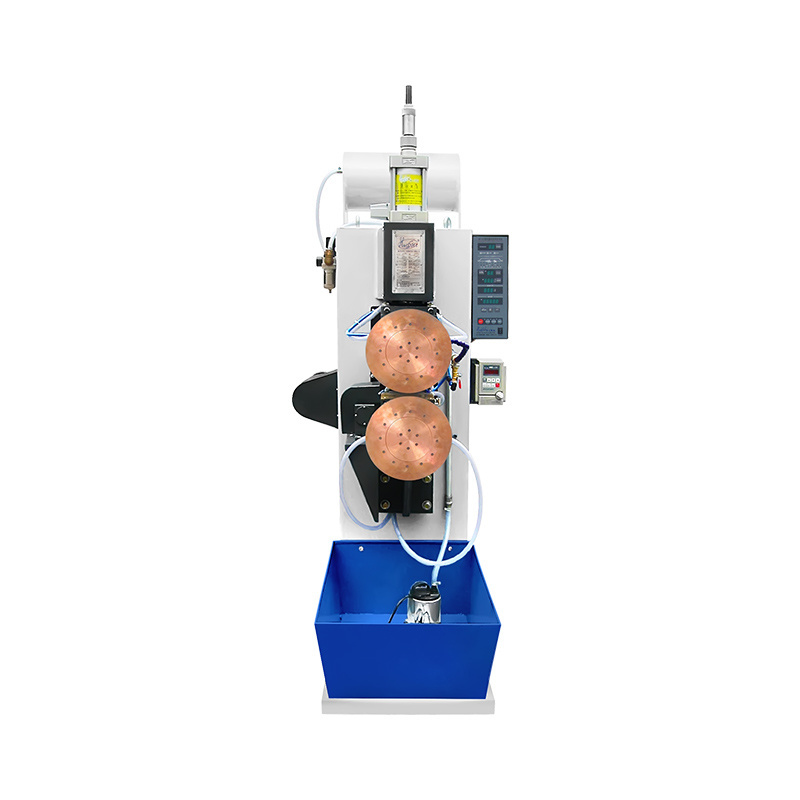

High quality super hard copper alloy welding wheel

Made of excellent material processing, not afraid of high temperature, not afraid of wear and tear, good electrical conductivity.

Shape structure and welding method

Design the right machine shape and mold according tothe welding product and extended welding arms.

Features of longitudinal rolling seam welding machine for fuel tank

1.Intelligent microcomputer controller with digital setting. Online computer programming, LED digital display, stable performance, convenient modification of the program online.

2.Digital circuit control; the components are imported from famous factories in the world to ensure the equipment could operate steadily in the long run.

3.SEMIKRON and IXYS silicon controlled from West Germany, IR silicon controlled from United States.

4.The transmission tile axis adopts the latest silver tile conductive technology from abroad.

5.Welding roll wheel adopts the alloy copper material from Japan.

6.The transformer adopts the high pure silicon steel sheet from Japan, good performance in magnet and electricity conductivity. Low consumption of electricity. Stronger and more stable power.

Specification

|

Model

|

Welding Wheel Manner

|

Input Voltage

|

Output Power

|

Output Current

|

|

WL-FSH-16K

|

Horizontal

|

220/ 380V

|

16KW

|

10000 A

|

|

WL-FSL-25K

|

Circular

|

220/ 380V

|

25 KW

|

12000 A

|

|

WL-FSH-25K

|

Horizontal

|

220/ 380V

|

25 KW

|

12000 A

|

|

WL-FSH-35K

|

Horizontal

|

380V

|

35 KW

|

16000 A

|

|

WL-FSZ-50K

|

Vertical

|

380V

|

50 KW

|

19500 A

|

|

WL-FSZ-75K

|

Vertical

|

380V

|

75 KW

|

24000 A

|

|

WL-FST-50K

|

Special Machine structure

|

380V

|

50 KW

|

19500 A

|

|

WL-FST-150K

|

Special Machine structure

|

380V

|

150 KW

|

40000 A

|

|

WL-FST-200K

|

Special Machine structure

|

380V

|

200 KW

|

50000 A

|

|

WL-FS-100K

|

Vertical

|

380V

|

100 KW

|

30000 A

|

Application and samples

We can provide customized service for you. Our engineers will discuss the specific welding requirement with you and come out withthe suitable technical proposal based on your samples or drawings.

Factory & Certificate

HWASHI

22

years+ experience welding solutions expert

Guangdong Hwashi Technology Inc. which was established in 2001, is located in Huizhou, Guangdong province in China. We are the high-tech enterprise which is specialized in developing, manufacturing, and selling of resistance welding machine, automatic welding machine and industrial robot station. We have total two manufacturing plants covering an area about 60000 square meters.There are about 200 staffs in Hwashi, and among which there are more than 20 mechanical and electrical engineers. Most of our engineers got more than 10 years experience in welding industry. Until now, we got more than 70 patents regarding the welding machine projects. Our machines have been exported to more than 70 counrties in the world. And we have local distributor in Russia, Turkey, Romania, Saudi Arabia, Malaysia, Indonesia, India, and USA, etc. who will provide you professional pre-sales and after-sales service in local.

Certifications

We have passed the international certifications such as

CE

certification,

ISO 9001

quality management system certification, Alibaba enterprise certification and design patents.

After-sales service & Customer visiting

1.spot welding machine

1 years warranty

except consumable parts

2.Plenty of technical support

online

is available

3.Quick Back-up Parts Available&Technical Assistance

4.

"Training Video","Instruction Book",

and

"Operation Manual"

will be offered

Packing & Delivery

Acceptable Delivery Terms

EXW, FOB, C&F, CIF, DDU, DDP

Quality Control

Strictly control all aspects of incoming materials, processing, assembly, commissioning, testing, packaging and shipping to ensure the performance and quality of welding products.

Professional Package

1. Whole film packaging machine;

2. Anti-collision package edge;

3. Wooden box and pallets with iron binding belt.

Service Team& feedback

Professional Team

Over the years, Hwashi has cultivated a large number of talented, dedicated and innovative Hwashi people. We have a professional team of experts with rich experience in electrical engineering, mechanical design and welding technology.

Since its establishment

22

years

ago, hwashi technology has traveled to all corners of the world, participated in more than

100

exhibitions

and served more than

8,000

customers

FAQ

Q1: What is the price of your machine?

Answer: our machines are customized for your requirements. If you want to get the appropriate price, please provide us the following information.

Answer: our machines are customized for your requirements. If you want to get the appropriate price, please provide us the following information.

* The material and thickness of your product

* The minimum and maximum size of your product

* The welding position of your products

* The automation level that you want to achieve

* It would be better if you can provide us the detailed product drawings so our engineer can come out with the suitable

technical proposal and price for you.

Q2: What is the warranty period of your machine?

Answer: our standard warranty period is one year after shipment. If you want to extend the warranty period, there will be extra cost.

Q3: What if my machine damaged doing the warranty period?

Answer: firstly, our engineer will help you to diagnose the problem via online guidance. if any parts damaged during the warranty period, we will send the parts to you for replacement free of charge. If you can not fix he problem by replacement of the new parts, we will send engineer to your factory to help fixing the machine.

Q4: What is the delivery time of your machine?

Answer: it depends on the complexity of your machine. Most of our standard machine we got in stock, then we can shape the machine with the seven days after receiving your payment. If you need the Customized machine, normally it would take about 30-90 days to complete the machine.

Q5: Can we send the sample to you for welding test?

Answer: yes. You can send us the samples for welding test and we will send you the pictures and videos after the testing. If you need, we can also send the samples back to your country so you can check the welding quality by yourself before ordering the machine.

Q6: Can you provide us the machine drawings and technical proposal?

Answer: yes. After receiving your detailed requirement and product drawings, our engineer will come out with the suitable

technical proposal with the basic machine concept drawings to you. Be size after you placing the order we will send you the more detailed design drawings of the machine to you for confirmation. Only after you confirming the drawings then we will start the manufacturing process.

Q7: What’s your payment terms?

Answer: we can accept the following payment terms: T/T, L/C, Western Union, Alibaba trade assurance. (we prefer you to choose the Alibaba trade assurance order. If you are not satisfied with the machine that you order, or we delay the shipping time, then you can apply the complaint on alibaba.com. )

Q8: How can we install the machine?

Answer: for some simple machines we will provide you the english operation manual, the operation video and also we will provide you the online guidance and training to your engineer so you can set up the machine easily. For some complicated machines, we will send engineer to your country to help installation and training. But there will be extra cost for Engineer, including the salary,visa cost, round-trip ticket cost, and accommodation fee will be covered by the buyer.

* The minimum and maximum size of your product

* The welding position of your products

* The automation level that you want to achieve

* It would be better if you can provide us the detailed product drawings so our engineer can come out with the suitable

technical proposal and price for you.

Q2: What is the warranty period of your machine?

Answer: our standard warranty period is one year after shipment. If you want to extend the warranty period, there will be extra cost.

Q3: What if my machine damaged doing the warranty period?

Answer: firstly, our engineer will help you to diagnose the problem via online guidance. if any parts damaged during the warranty period, we will send the parts to you for replacement free of charge. If you can not fix he problem by replacement of the new parts, we will send engineer to your factory to help fixing the machine.

Q4: What is the delivery time of your machine?

Answer: it depends on the complexity of your machine. Most of our standard machine we got in stock, then we can shape the machine with the seven days after receiving your payment. If you need the Customized machine, normally it would take about 30-90 days to complete the machine.

Q5: Can we send the sample to you for welding test?

Answer: yes. You can send us the samples for welding test and we will send you the pictures and videos after the testing. If you need, we can also send the samples back to your country so you can check the welding quality by yourself before ordering the machine.

Q6: Can you provide us the machine drawings and technical proposal?

Answer: yes. After receiving your detailed requirement and product drawings, our engineer will come out with the suitable

technical proposal with the basic machine concept drawings to you. Be size after you placing the order we will send you the more detailed design drawings of the machine to you for confirmation. Only after you confirming the drawings then we will start the manufacturing process.

Q7: What’s your payment terms?

Answer: we can accept the following payment terms: T/T, L/C, Western Union, Alibaba trade assurance. (we prefer you to choose the Alibaba trade assurance order. If you are not satisfied with the machine that you order, or we delay the shipping time, then you can apply the complaint on alibaba.com. )

Q8: How can we install the machine?

Answer: for some simple machines we will provide you the english operation manual, the operation video and also we will provide you the online guidance and training to your engineer so you can set up the machine easily. For some complicated machines, we will send engineer to your country to help installation and training. But there will be extra cost for Engineer, including the salary,visa cost, round-trip ticket cost, and accommodation fee will be covered by the buyer.

Hot Searches