- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.3-1mm

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

KINGREAL

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

100*150*200

-

Weight:

-

15000 kg

-

Product name:

-

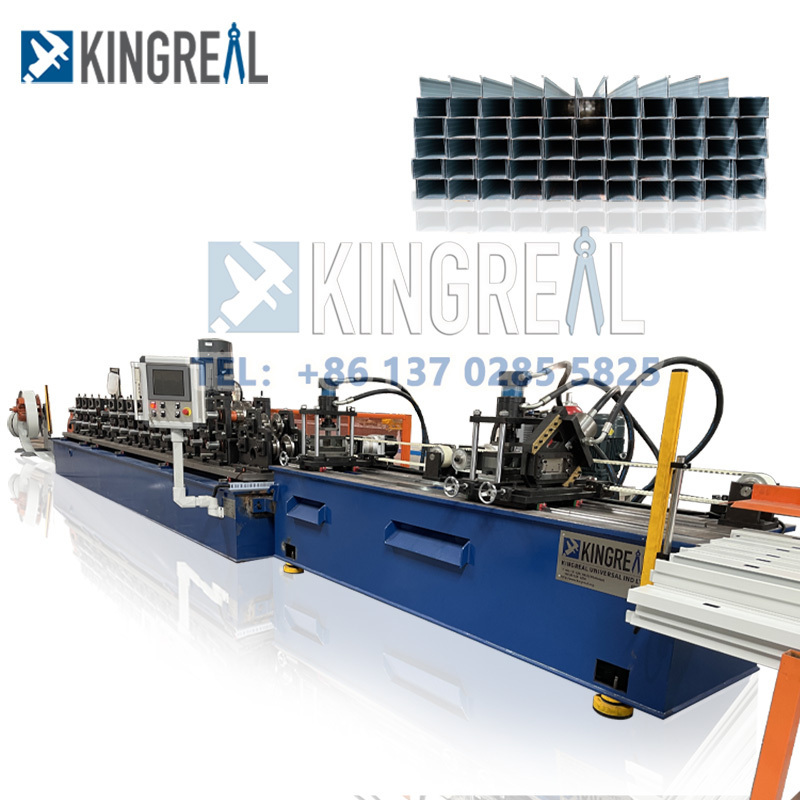

Drywall Stud and Track Roll Forming Machine C U Z H Profiles

-

Usage:

-

Metal ceiling production

-

Raw material:

-

Gi Steel, Aluminum

-

Thickness:

-

0.3-1.0mm

-

Roller material:

-

Cr12 Steel quenched

-

Cutting blade material:

-

CR12MOV

-

Control system:

-

Touch screen

-

Motor brand:

-

Mitsubishi

-

PLC:

-

Fatek

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Steel

-

Production Capacity:

-

30 m/min

-

Rolling thinckness:

-

0.3-1mm

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

KINGREAL

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

100*150*200

-

Weight:

-

15000 kg

-

Product name:

-

Drywall Stud and Track Roll Forming Machine C U Z H Profiles

-

Usage:

-

Metal ceiling production

-

Raw material:

-

Gi Steel, Aluminum

-

Thickness:

-

0.3-1.0mm

-

Roller material:

-

Cr12 Steel quenched

-

Cutting blade material:

-

CR12MOV

-

Control system:

-

Touch screen

-

Motor brand:

-

Mitsubishi

-

PLC:

-

Fatek

Products Description

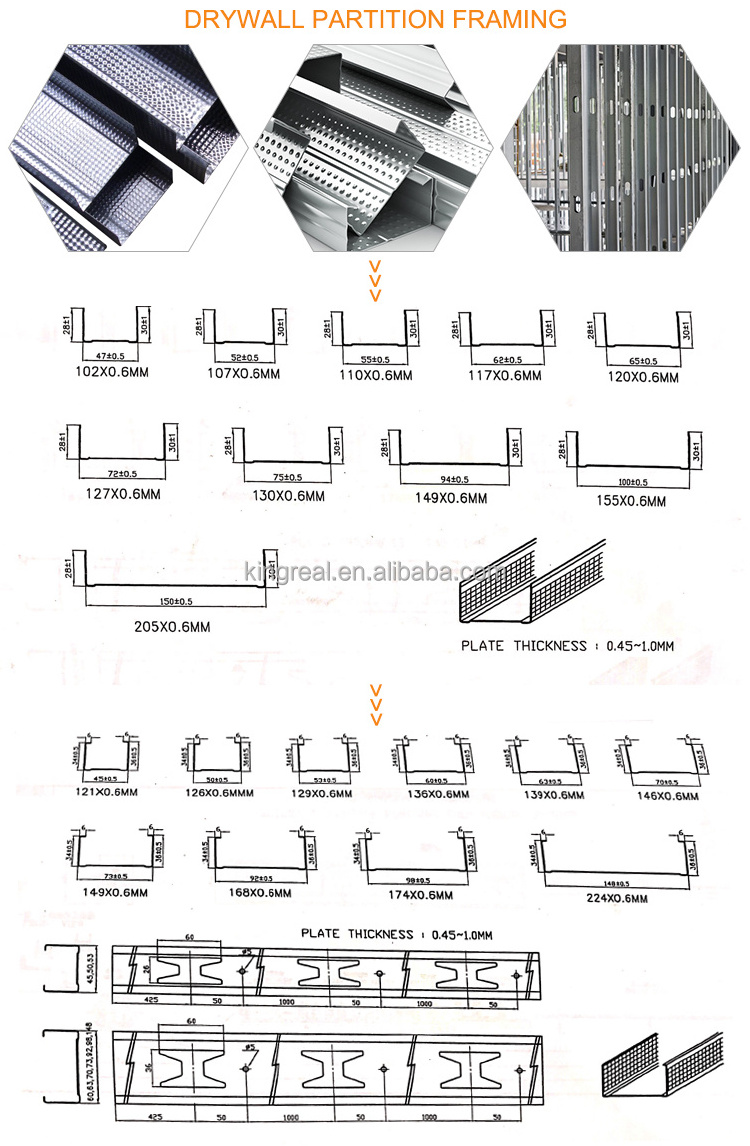

Drywall

Stud and Track

Roll Machine

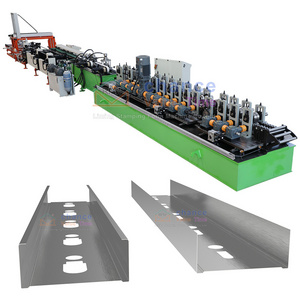

Stud And Track Profile Roll Forming Machine for drywall profiles is used to produce keel and rail products, mainly for lightweight partition walls. The production speed is up to 110m/min, and we have the accumulation of rich experience in the history. The drywall profile roll forming machine can automatically adjust the roller position through the full-color touch screen to produce different widths of drywall profile products, the adjustable width range is 40-150mm.

Currently more popular shapes C/U/Z/H, etc. can be produced, and can be designed and produced according to customer needs.

Below are some of the products we have done the machine to produce:

Product Features

1.Through the operation of the full-color touch screen, adjust the required width of the product

Produce width range: 40-150mm.

2.Saves production costs and allows the production of stud and track on one machine.

3.Non-manual manual operation reduces a lot of errors and saves a lot of test costs.

4.Its speed is faster, the speed range can be 80-110 meters per minute, which greatly improves the production efficiency

5.The brand-name motor used is Yaskawa, Japan, and the life time is greatly extended, and the use is guaranteed.

6.Easy operation, low maintenance cost finite sizing(any size within machine range),help to save material.

7.KINGREAL has installed a lot of this equipment in the Middle East, well-known manufacturers such as USG, Jawdah are using our equipment

Reference Date

|

Machine Name

|

Drywall Profile Roll Forming Machine

|

|

Products Name

|

C-Shape Profiles, U-Shape Profiles

|

|

Products sizes

|

As per requirements

|

|

Automation

|

Manual Operation/Full-Automatic Production with PLC

|

|

Certificate

|

CE certificate, ISO 9001 certificate

|

|

Machine Power

|

380V 50HZ or according with customers‘ request

|

|

Speed

|

0~120m/min adjustable

|

|

Main Features

|

Equipped with air cooling system, Famous brand hydraulic system, light curtain safety protection

|

Equipped with double-head manual decolier

Increase productivity

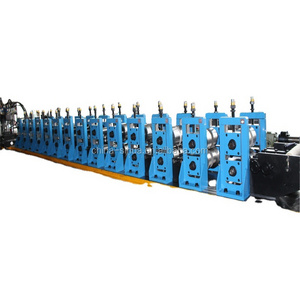

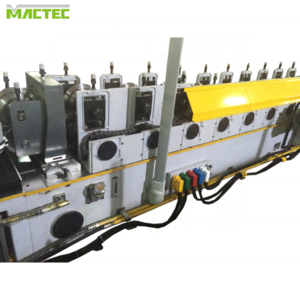

Main roll forming machine

(1)

The speed can reach 80-100m/min

(other suppliers can only provide 30-50m/min equipment)

(2)Through the touch screen,

the width and narrowness can be adjusted automatically with high precision, and the error range is ±0.1mm

,

which avoids a lot of waste and errors caused by manual operation.

(3) Each set of rollers is equipped with a

Heavy T type speed reducer

, which can automatically move to the corresponding position with high precision.

Used to cut a specific length after product forming.

The production speed of 80-100 m/min, compared with the old equipment, the speed is increased by 70%

, which speeds up the production efficiency and has a significant effect on the production of enterprises.

Working Procedure

Hydraulic Decoiler →Main Roll Forming Machine →Shearing Station →Output Table→Electrical & Hydraulic System

Application

The products produced by the keel machine are often used in the decoration of factories, office buildings, offices, large and medium-sized shopping centers, shopping malls, supermarkets and other indoor building decoration.

Related products

Why Choose Us

KINIGREAL MACHINERY

company has rich experience in the design, production and installation of roll forming machines.

At present, our company has completed the design and production of more than 500 different molding machines. Especially in India, Middle East, Vietnam, Russia and other regions, we have Numerous project success stories.

The following is our machine packing and loading process.

1. Use the plastic protective film

2. Stick the mark

3. Prepare the trailer for loading

4. Secure equipment

Localized service points in other countries and regions are also in progress

FAQ

Q2. How to visit your factory?

A2. There are 2 ways: either by plane or by train to Foshan/Guangzhou port. We will be picking you up in plane/train station, then we can go together.

Q3. How long will you send the proposal and offer?

A3. We will need about 3~7 days to design the proposal upon collecting all details of the ab- ove mentioned info necessary.

Q4. When will you tell me the price?

A4. After confirming all detailed configurations of the machine line, that we are able to make offer for it.

Q5. How long do you need to produce the machine?

A5. Usually one week for installing and teaching workers about how to operate.

Q6. How many people will come to install and commission the machine line?

A5. Usually 1 engineer is enough to do all the things. All his expense during this travel will be paid by buyer accordingly.

Q3. How long will you send the proposal and offer?

A3. We will need about 3~7 days to design the proposal upon collecting all details of the ab- ove mentioned info necessary.

Q4. When will you tell me the price?

A4. After confirming all detailed configurations of the machine line, that we are able to make offer for it.

Q5. How long do you need to produce the machine?

A5. Usually one week for installing and teaching workers about how to operate.

Q6. How many people will come to install and commission the machine line?

A5. Usually 1 engineer is enough to do all the things. All his expense during this travel will be paid by buyer accordingly.

Hot Searches