- Product Details

- {{item.text}}

Quick Details

-

Rated Voltage:

-

10-500kV

-

Tensile Strength:

-

High

-

Name:

-

DISTRIBUSION SILICONE INSULATORS LINE POST

-

Standard:

-

IEC61952

-

Certificate:

-

Test Report/CCPIT/ISO9001

-

Color:

-

Grey

-

Voltage:

-

10-500kV

-

Bending strength:

-

50-430KN

-

Sample:

-

Supplied

-

Supply type:

-

Customization

-

OEM:

-

Support

Quick Details

-

Place of Origin:

-

Shaanxi, China

-

Brand Name:

-

TID POWER

-

Model Number:

-

TID POWER

-

Rated Voltage:

-

10-500kV

-

Tensile Strength:

-

High

-

Name:

-

DISTRIBUSION SILICONE INSULATORS LINE POST

-

Standard:

-

IEC61952

-

Certificate:

-

Test Report/CCPIT/ISO9001

-

Color:

-

Grey

-

Voltage:

-

10-500kV

-

Bending strength:

-

50-430KN

-

Sample:

-

Supplied

-

Supply type:

-

Customization

-

OEM:

-

Support

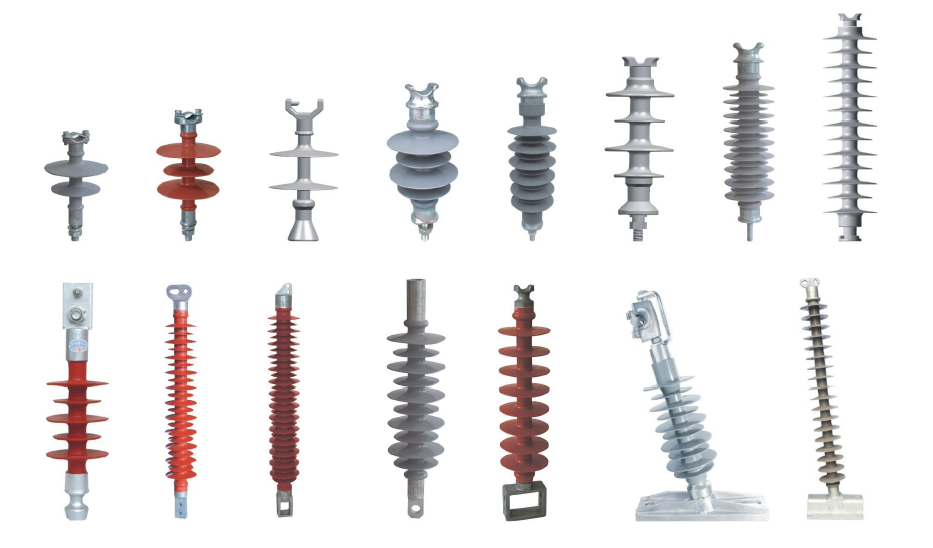

DISTRIBUSION SILICONE INSULATORS LINE POST

Silicone rubber line post insulator have very good ultimate solution,due to its hydrophobicity,this material inherently resists water filming thereby limiting leakage currents.silicone rubber insulators reduce leakage currents ,even when contaminated and require less frequent washing.the savings in such maintenance costs are added benefits of using silicone rubber insulator.

The Performance benefit of distribution line post insulator are listed below:

1.Improves Reliability (by minimizing interruptions and outages due to vandalism,Pole fires,and flashovers in all types of enviroments)

2.Eliminates or Reduces Maintenance (such as washing and trouble calls) and is compatible with existing plant

3.Improve Power Quality(less RI and TVI)

4.Energy Efficiency (lower losses due to lower leakage currents)

5.Safety (light weight for handling and installation)

6.Service Life( consistent performance over its service life)

7.Life Cycle Cost(Savings over ceramic insulators)

Application:

Distribution silicone line post insulators are used on overhead distribution lines operating at and below 69KV.These insulators are commonly installed on metal,concrete or wooden structures to horizontally or vertically support the line conductor.also these insulators can be used to support high voltage conductor jumpers or leads.

Material:

1.Core rod

The core rod of the insulator is made of a high quality,epoxy resin,Fiberglass rod that has been specially formulated for electrical and mechanical applications.

2.Housing

The housing (includes sheath and sheds)of the insulator is one piece,high temperature vulcanized ,injection molded silicone rubber that is chemically bonded to the core rod.This ensures that the interface between the rubber and rod is impenetrable against moisture ingress.TID Tech uses its own proprietary silicone rubber formula in the manufacture of its insulators.the formulations has silicone rubber as the base polymer material with additives to enhance its performance in wet contaminated environments.

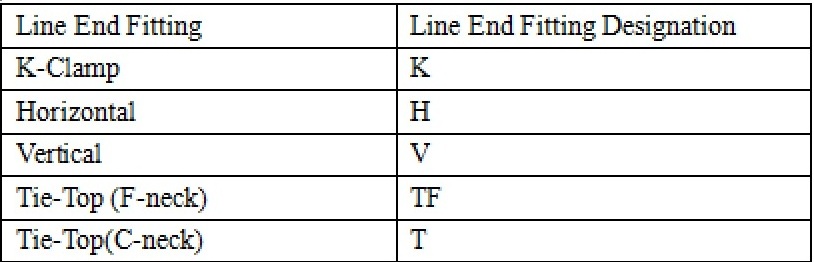

3.Line End Fitting

The line end fitting of Line Post Insulator are available in four different configurations: Horizontal or Vertical Clamp-Top,Tie-Top,or K-clamp.

End fittings on line Post Insulators are made of corrosion resistant aluminum alloy or galvanized iron castings.

Section Length Adjustment

|

Line End Fitting |

Line End Fitting Designation |

|

K-Clamp |

K |

|

Horizontal |

H |

|

Vertical |

V |

|

Tie-Top (F-neck) |

TF |

|

Tie-Top(C-neck) |

T |

Clamp-Top

The conventional horizontal and vertical trunnion accommodates a standard Line post insulator,bolted conductor clamp.One the horizontal design the line end fitting has and additional eye for the attachment of other devices during installation or maintenance activities.

Tie-Top

The tie-top is designed for tying a conductor to the neck of the insulator.it is a available in two standard neck sizes: C or F-neck.

K-clamp

Some advantages of the K-Clamp include:

1.Excellent corrosion resistant aluminum casting

2.A long,smooth contoured conductor clamping zone

3.The clamp accommodates a full range of conductor size

4.A single captive live-line operable bolt

5.All parts are captive

6.Its overall length permits standard cover up hoods to effectively cover all insulator sheds.

7.The design can be installed in either a horizontal or vertical configuration.

8.Inventory reduction is accomplished because one insulator is used for both configurations and a separate clamp is not required.

9.The price of the new insulator is cost comparative with the purchase of a standard turnnion post insulator and a separate clamp

10.Substantial labour cost savings in stringing ,sagging and conductor clamping

11.Other savings related to shipping,stocking and maintenance.

Base end Fitting

The standard base for line post insulator is a round flat iron bas with a threaded hole that accommodates a standard insulator stud or bolt.for other special bases contact TID tech.