- Product Details

- {{item.text}}

Quick Details

-

Type:

-

Processing machine, Coconut juice extracting

-

Voltage:

-

220V / 380V

-

Power:

-

200KW

-

Weight:

-

1500 KG

-

Dimension(L*W*H):

-

Customized

-

Year:

-

2024

-

Product name:

-

Coconut water processing machine

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Material:

-

304 Stainless Steel

-

Raw material:

-

Coconut meat

-

Capacity:

-

1TPH-10TPH

-

Final product:

-

Coconut water and milk

-

Heating source:

-

Steam

-

Feature:

-

High Efficiency Easy Operate

-

Package:

-

Wooden Case

Quick Details

-

Marketing Type:

-

New Product 2024

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

Beyond

-

Type:

-

Processing machine, Coconut juice extracting

-

Voltage:

-

220V / 380V

-

Power:

-

200KW

-

Weight:

-

1500 KG

-

Dimension(L*W*H):

-

Customized

-

Year:

-

2024

-

Product name:

-

Coconut water processing machine

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Material:

-

304 Stainless Steel

-

Raw material:

-

Coconut meat

-

Capacity:

-

1TPH-10TPH

-

Final product:

-

Coconut water and milk

-

Heating source:

-

Steam

-

Feature:

-

High Efficiency Easy Operate

-

Package:

-

Wooden Case

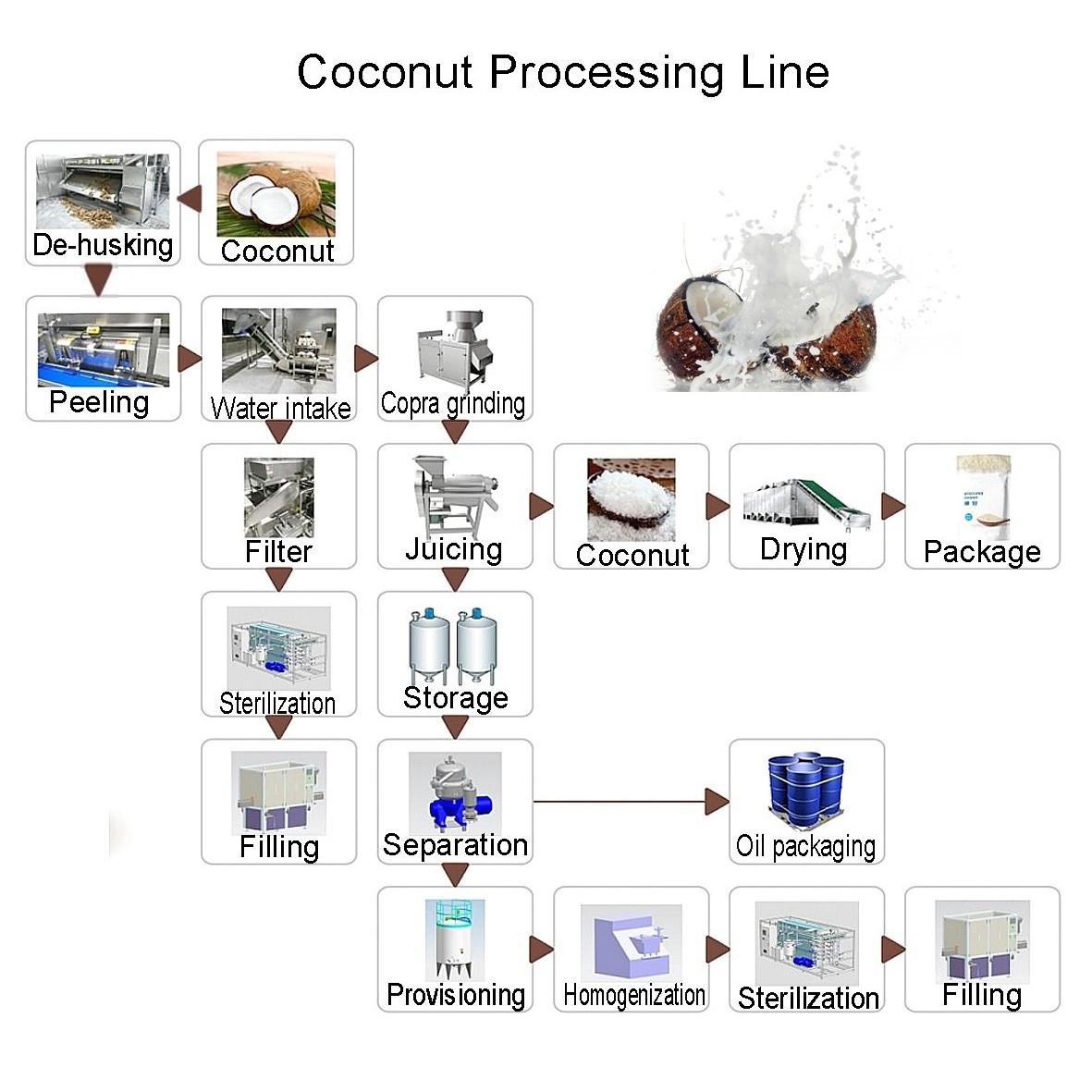

Coconut water processing machines are used to extract and process coconut water from coconuts. These machines typically consist of several components, including a coconut dehusking machine, coconut opening machine, coconut grating machine, coconut milk extractor, and coconut water filtration system.

The coconut dehusking machine is used to remove the outer husk of the coconut, while the coconut opening machine is used to open the coconut and separate the coconut water from the meat. The coconut grating machine grates the coconut meat, which is then used to extract coconut milk.

The coconut milk extractor separates the coconut milk from the grated coconut meat, leaving behind the coconut water. Finally, the coconut water filtration system is used to filter the coconut water, removing any impurities and ensuring its purity.

These machines can be manual or automated, depending on the scale of production. They are commonly used in coconut water processing plants or by small-scale producers who want to process coconut water for commercial sale.

Overall, coconut water processing machines play a crucial role in efficiently extracting and processing coconut water, ensuring its quality and freshness for consumption.

Coconut water processing machines are used to extract and process coconut water from coconuts. These machines typically consist of several components, including a coconut dehusking machine, coconut opening machine, coconut grating machine, coconut milk extractor, and coconut water filtration system.

The coconut dehusking machine is used to remove the outer husk of the coconut, while the coconut opening machine is used to open the coconut and separate the coconut water from the meat. The coconut grating machine grates the coconut meat, which is then used to extract coconut milk.

The coconut milk extractor separates the coconut milk from the grated coconut meat, leaving behind the coconut water. Finally, the coconut water filtration system is used to filter the coconut water, removing any impurities and ensuring its purity.

These machines can be manual or automated, depending on the scale of production. They are commonly used in coconut water processing plants or by small-scale producers who want to process coconut water for commercial sale.

The coconut water and milk line is composed of coconut meat grinding machine, coconut milk extractor, coconut milk pasteurizer, UHT sterilizer and coconut water and milk filling machine.

Single Strength Coconut water

is a refreshing and cooling drink. Its sodium and potassium content makes it an ideal drink for rehydration. In a healthy, undamaged coconut, the water is even sterile. Fresh coconut after dehusking and deshelling, then use one needle to pierce one hole on the coconut to extract coconut water. After extraction, coconut water is filtered. Filtration can be done using a double cloth filter. This is especially important for mature coconut water, as dry husk fibres and dirt from the shell of mature nuts can easily get into the coconut water during extraction. After filtration, the coconut water is quickly cooled to retard any deterioration reactions. Then, it is sent for separation, homogenizing, degassing, subsequent pasteurization and aseptic packaging.

If coconut water is extracted at a location away from the aseptic packaging site, the filtered coconut water can be packed into food grade plastic bags, quickly cooled and transported to downstream processing. The single strength coconut water content is 92%-95% and soluble solids is about 12 brix.

Concentrated coconut water: Concentrated coconut water is about 60-65 brix and water content is about 35%-40%. Fresh coconut water after extracting, filtering, cooled to 10 ℃ and storing into double layers insulation tanks. Then the low-temperature coconut water will be prepasteurization and separation. Then, it goes into a multiple-effect evaporation stage to increase °Brix levels. Usually, the product is concentrated to 60-65 °Brix and packed into 200 kg plastic bags in drums for bulk transportation under ambient conditions. It is recommended that the concentrate coconut water will be stored at below zero temperature for 2 years.

Coconut milk/cream : Coconut milk and cream are produced from 10-13 months old mature coconuts when the kernel is hard and thick. They are natural oil-in-water emulsions extracted from the mature coconut kernel. The difference between coconut milk and cream is the amount of fat. The fat content of the coconut milk is 5%-20%, whereas coconut cream reaches to 20%-50%. To extract coconut milk for industrial manufacturing purposes, mature coconuts go through deshelling and paring. Pieces of kernels are then sent into industrial-scale cutters and grinders. Next, grated coconut kernel then goes into a series of screw extractors to extract coconut milk. The residual kernel from this first press is then mixed with water before it is pressed again to increase extraction yield. After extraction, coconut milk is filtered to remove large contaminants. It can then be standardized to a pre-determined level of fat and blended with other ingredients. Finally, coconut milk is homogenized, degassed, pasteurized and aseptically filled into aseptic bags or small package like bottles or tin cans.

Coconut oil: Coconut oil is one of the main products traditionally derived from the coconut kernel. Coconut oil processing methods or technologies are classified into two major types based on copra or fresh coconut kernel used. The oil extraction technology, which starts with copra as the raw material, is commonly known as the dry process. While the method that uses fresh coconuts as starting material is generally called the fresh-wet or fresh-dry process. Based on different separation methods, coconut oil can be classified into two types – RBD coconut oil and virgin coconut oil (VCO). The former is refined, bleached and deodorized (RBD) from dry extraction, while the latter is produced by fresh-wet and fresh-dry extractions.

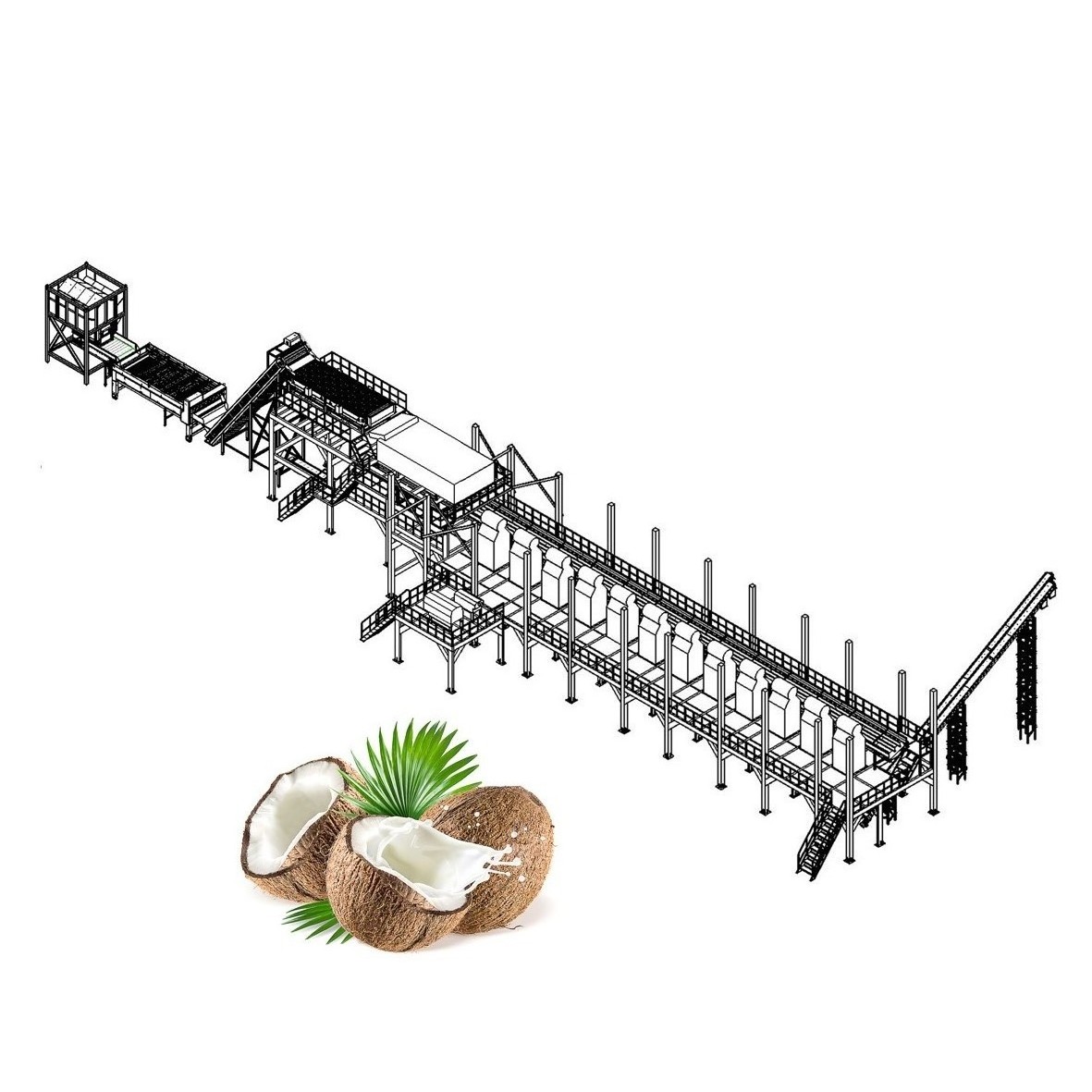

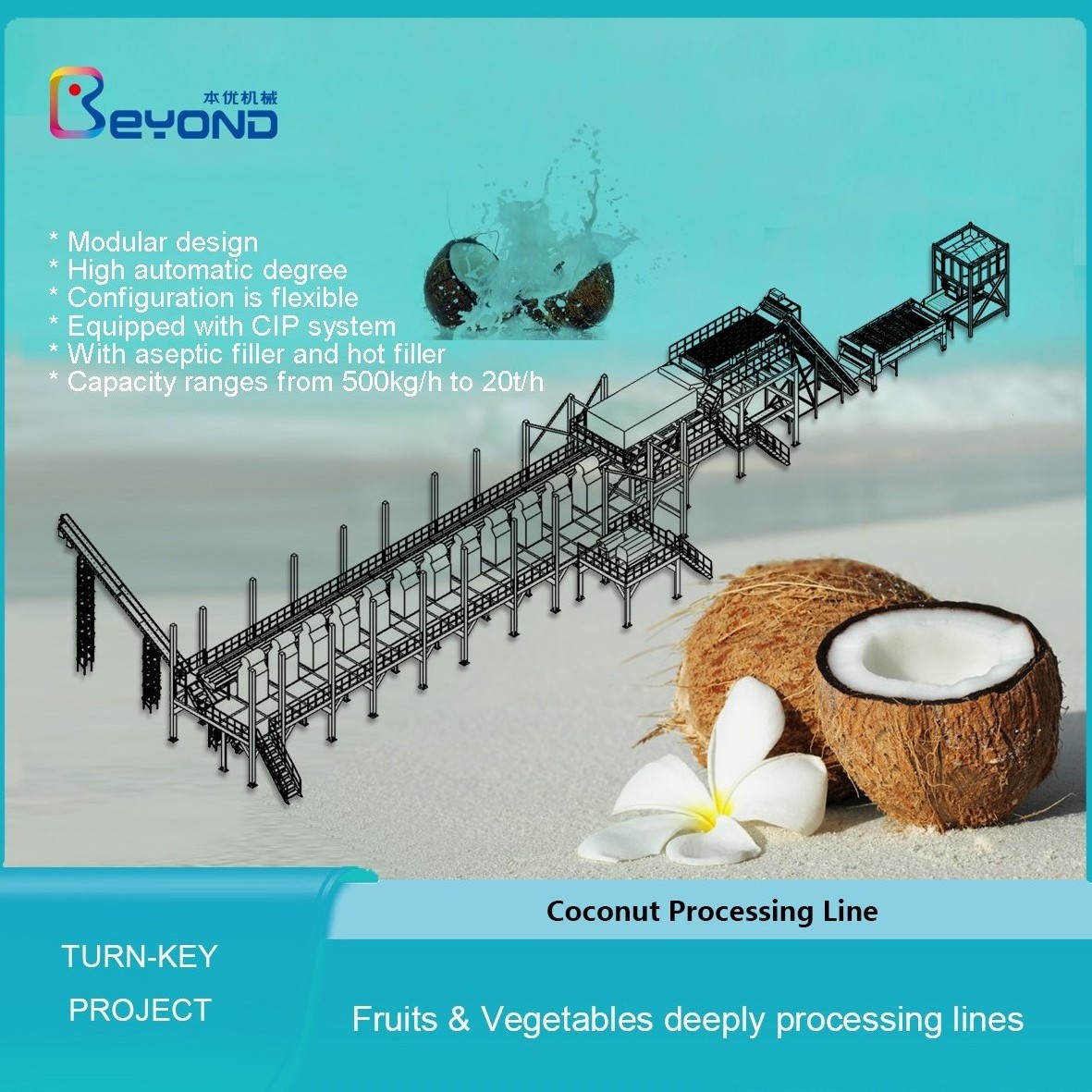

Suitable for all kinds of coconut to produce coconut water, coconut milk, juice with coconut ,coconut powder and etc. This processing line is combined with peeler, pulverizer, screw separator, filtration, disc centrifugal separator, blending system, degasser, homogenizer, sterilizer, filler, flusher, autoclave, ink coder and etc. With advanced design philosophy, high degree of automation; Main equipments are all made of high quality food grade stainless steel, accords with the hygienic requirements of food processing.

* Produce coconut water, coconut milk, coconut juice and etc

* Capacity ranges from 500kg/h to 20t/h,designed by the customer's needs

* Configuration is flexible, according the requirement of client to prepare the suitable machine

* With aseptic filler and hot filler

* Modular design, which can combine different processing technique

* High automatic degree, labor-saving

* Equipped with CIP to make clean easy

* Material contacted with production is SUS304 stainless steel, fully meets the food hygiene safety requirements

PARAMETER

| Raw Material | Coconut shell and coconut meat |

| End products | coconut water and milk, coconut cream, coconut oil |

| End Package | Aseptic bags in drums, bottles, tin cans, cartons |

| Processing products | UHT water and milk |

End Products and Package of Coconut Processing Line

--Concentrate Coconut water filled into aseptic bags(5kg,220kg or 1000kg)

--Single strength coconut water(Non-concentrated coconut water)filled into tin cans,bottles or asptic bags.

--Coconut milk/cream filled into aseptic bags,tin cans or bottles.

--Desiccated Coconut filled into poly bags,jars or pouches.

--Virgin Coconut Oil(VCO)filled into bottles or barrels.

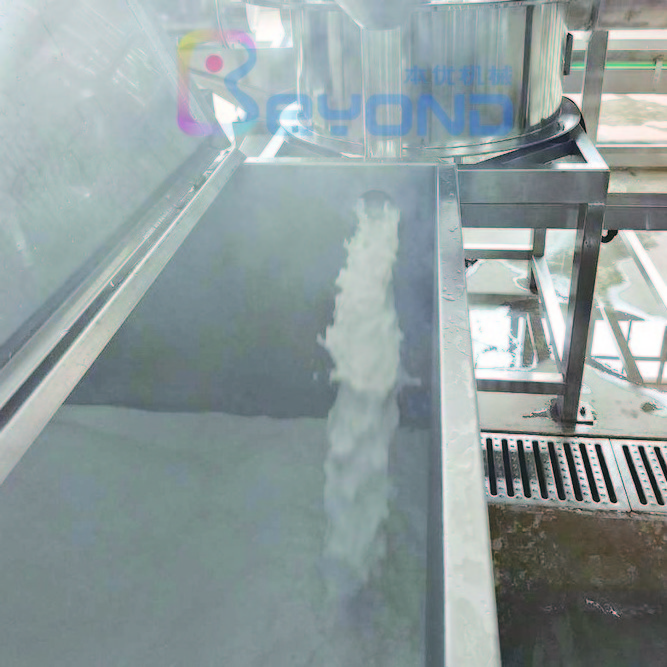

Coconut milk extracting machine

There are two types of machines for coconut milk extracting:one is using belt press,the other is using double screw juice extractors.

The double screw type juice extractor usually has a higher yield rate than the belt press with about 55%-60%.The pneumatic double screw type extracting machine working principle:coconut kernel from the feed hopper led by screw.The cavity of the screw is smaller and smaller,press the coconut kernel,coconut milk is pressed out and collected into a vessel,the solid after extracted the coconut milk is discharged out through the interspaces between the screw and pressure regulating head.

The belt press coconut milk extractor is used for a higher capacity coconut milk processing plant.The coconut meat will be ground into flakes,and then feed into the belt press extractor.During extracting,the RO pure water will be added.

Coconut water and milk pasteurizer/sterilizer

There are two sterilizing processes during coconut water and milk processing.The first process uses plate-type pasteurizer to do pre-pasteurization(70-95℃ for 15-20 seconds)when extracting out the coconut water and milk,then storage into batch tanks instantly.The second process is that before coconut water and coconut milk filling,we use a tubular type UHT sterilizer(137-140℃ for 3-5 seconds)or DSI sterilizer to kill all the bacteria in the products.After sterilizing,the coconut water and milk can do aseptic filling into tetra pak cartons or hot filling into bottles or tin cans.

Coconut water and milk filler

There are three main products for coconut:single strength coconut water and coconut milk can do aseptic filling into aseptic brick cartons or hot filling into PET or glass bottles and small tin cans;Concentrated coconut water will be filled into aseptic bags in drums for repacking.

Productivity, quality and cost effectiveness

We attach importance to the productivity, quality and cost-effectiveness of fruit and vegetable processing equipment. Our high-tech processing machinery provides high operational value and helps you produce the highest quality final products. In terms of coconut or mango processing equipment, our optimized technology and special machines help to obtain high-quality sauce, sauce, mud and fruit juice.

Our professional expert team ensures the high efficiency and ideal performance of the whole series of fruit and vegetable processing equipment. We are committed to saving time in our equipment to process fruits and vegetables faster. We also apply this time efficiency to our manufacturing process in order to deliver your processing equipment as soon as possible.

Pre sales services

After sales services

1.

Equipment warranty period

: We provide a one-year free warranty service for mechanical equipment. If any non-human caused problems occur during the warranty period, we will provide free repair or replacement services.

2.

Maintenance and upkeep services

: We provide regular or irregular equipment maintenance and upkeep services to ensure the normal operation of the equipment. We will provide 24-hour online technical support services.

3.

Accessory supply

: We guarantee to provide original factory accessories in a timely manner in case of equipment damage or replacement of parts.

4.

Training services

: In order to enable customers to effectively operate and maintain equipment, we will provide equipment operation and maintenance training.

5.

Installation and debugging

: We will provide equipment installation and debugging services to ensure that the equipment is installed correctly and can operate normally.