- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

1500*4300*17000mm

-

Weight:

-

24 tons

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Online support

-

Product name:

-

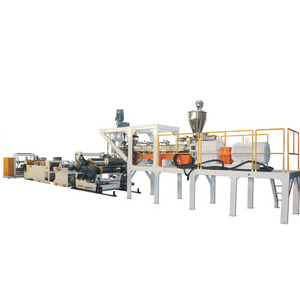

Multifunctiol Silicone Coating Machine

-

Structural type:

-

double plate

-

Machine speed:

-

10-120m/min

-

Core diameter:

-

76mm/3"

-

Max winding OD:

-

800mm

-

Max width:

-

1200mm

-

winding method:

-

double station

-

Application1:

-

PP/PE/BOPP/Pet film

-

Application2:

-

release paper, Non-woven

-

Certification:

-

ISO

Quick Details

-

Voltage:

-

220V/380V

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

HHL

-

Dimension(L*W*H):

-

1500*4300*17000mm

-

Weight:

-

24 tons

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Online support

-

Product name:

-

Multifunctiol Silicone Coating Machine

-

Structural type:

-

double plate

-

Machine speed:

-

10-120m/min

-

Core diameter:

-

76mm/3"

-

Max winding OD:

-

800mm

-

Max width:

-

1200mm

-

winding method:

-

double station

-

Application1:

-

PP/PE/BOPP/Pet film

-

Application2:

-

release paper, Non-woven

-

Certification:

-

ISO

Application

This machine could finish the silicon treatment of the following items:PP film, pe film, BOPP film ,pet film, nonwoven, release paper, Pearly membrane, front tape and so on.

This machine could finish the silicon treatment of the following items:PP film, pe film, BOPP film ,pet film, nonwoven, release paper, Pearly membrane, front tape and so on.

|

Type

|

HTB1200

|

|

[m/min] machine speed

|

10-120

|

|

structural type

|

(double plate)

|

|

[mm] core diameter

|

76/3'

|

|

winding method

|

double station

|

|

tension control

|

frequency motor

|

|

[mm] Max winding OD

|

800

|

|

mm drying tunnellength

|

12000

|

|

KW Rated Power

|

130

|

|

mm W*H*L

|

1500*4300*17000

|

|

KG total weight

|

24000

|

Processing method

Unwinding—corona treatment –print-gluing or silicon treatment-cool— UV Curing –winding

Unwinding—corona treatment –print-gluing or silicon treatment-cool— UV Curing –winding

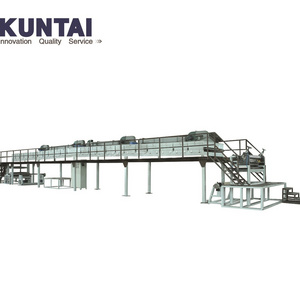

Main Feature

Duplex winding and unwinding system

Programmable controlling system, user friendly HMI, high Automation

AC electrical motor , encoder and low friction cylinder and the close loop vector control frequency converters consisted in

Tension control system . the procedure comprised in PLC programmable module.

Coating by the Intaglio roller ; silicon treatment finished by 2 or 3 rollers

Controlled by thermostatic system ,The drying channel comprised in multiple sections and each section's temperature and Waste discharge work independently . air flow could be adjusted according to the different manufacturing technique.

The guiding roll worked synchronous with the main machine by the vector control,Web-guiding system was set up at the exit of the oven

Duplex winding and unwinding system

Programmable controlling system, user friendly HMI, high Automation

AC electrical motor , encoder and low friction cylinder and the close loop vector control frequency converters consisted in

Tension control system . the procedure comprised in PLC programmable module.

Coating by the Intaglio roller ; silicon treatment finished by 2 or 3 rollers

Controlled by thermostatic system ,The drying channel comprised in multiple sections and each section's temperature and Waste discharge work independently . air flow could be adjusted according to the different manufacturing technique.

The guiding roll worked synchronous with the main machine by the vector control,Web-guiding system was set up at the exit of the oven

S type dual cooling rollers and composite roller

UV Curing device

Heating resource: electric power

Oven cap with pneumatic opening type ,tension control system equipped with the floating roller (swimming roll)

Non-stop relay of the raw material

Man-machine interface centralized control system.

Option

Fault Diagnosis system or intelligent management system.

UV Curing device

Heating resource: electric power

Oven cap with pneumatic opening type ,tension control system equipped with the floating roller (swimming roll)

Non-stop relay of the raw material

Man-machine interface centralized control system.

Option

Fault Diagnosis system or intelligent management system.

Q1: What Industry is your product suitable for?

A1:Our machines are widely used in the fields of disposable hygienic products,disposable medical products, clothing, textile fabrics, self-adhesive labels, medical tape, plaster backing, and various othercoating compounds.

Q2:What if the machine fails during use?

A2:Our machines will be carefully inspected and ensured before delivery,and we will provide the correct instructions for use of the products. In addition, our products support lifetime warranty service, if there any question during using our products please consult our work personnel.

Q3: When can I get the machine after payment?

A3:The product production time about 45-60 days. We will deliver it on time as the date we agreed both side.

Q4: How can I install my machine when it arrives?

A4:We will provide installation videos and tutorials, or send our engineer to your side ASAP

you get all your machines ready, for testing and teaching your technicians how to run the machine.

you get all your machines ready, for testing and teaching your technicians how to run the machine.

Q5: What payment do you accept?

A5:We generally accept T/T or L/C, and we can negotiate the payment method.

A5:We generally accept T/T or L/C, and we can negotiate the payment method.

Hot Searches