- Product Details

- {{item.text}}

Quick Details

-

Max. Spindle Speed (r.p.m):

-

4500 r.p.m

-

Max. Weight of Workpiece(kg):

-

1000

-

Spindle Bore(mm):

-

62mm or 87mm

-

Width of bed (mm):

-

300 mm

-

Spindle Motor Power(kW):

-

7.5

-

Max. Turned Length (mm):

-

450

-

Travel (X Axis)(mm):

-

160 mm

-

Travel (Z Axis)(mm):

-

500 mm

-

Positioning Accuracy (mm):

-

0.011

-

Repeatability (X/Y/Z) (mm):

-

0.004

-

Place of Origin:

-

Liaoning, China

-

Dimension(L*W*H):

-

2850*3000*18000MM

-

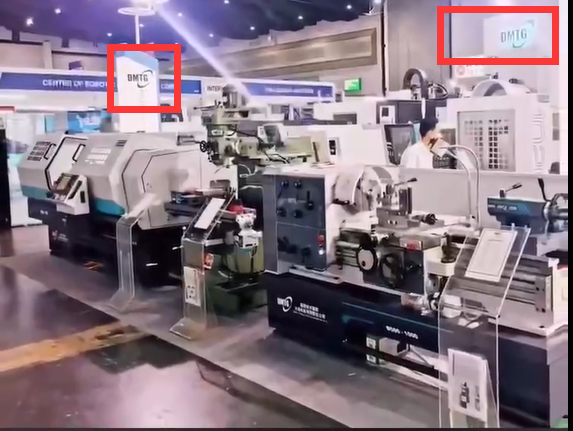

Brand Name:

-

DMTG

-

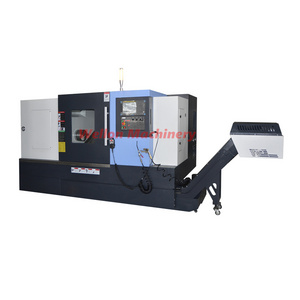

Model Number:

-

CLS20

-

Voltage:

-

220v/380v

-

Weight (KG):

-

4000

-

Marketing Type:

-

Hot Product

-

Product name:

-

DMTG Lathe Machine

-

Machine Type:

-

Cnc Slant Bed Lathe Machine

-

Function:

-

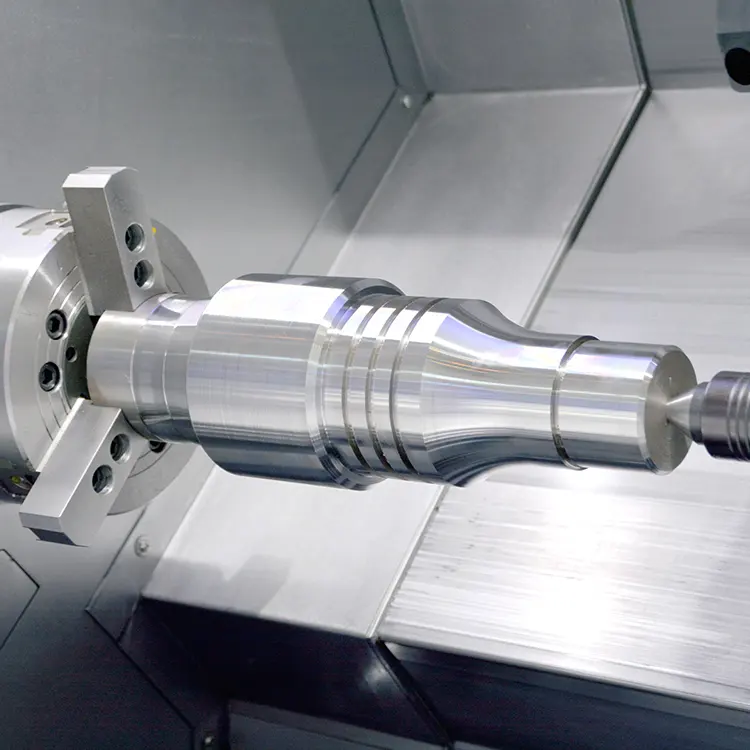

Boring Machine Turning Milling Drilling Threading Cutting Machine

-

Key word:

-

Metal CNC Turning Lathe Machine High Precision XYZ Axis Lather

-

CNC or Not:

-

CNC Automatic Hydraulic Working Metal Process Lathe Machine

-

Control system:

-

FANUC SIEMENS Mitsubishi GSK(optional)

-

Stock Or not:

-

With Stock And Ready To Ship

-

After-sales:

-

On Site Or Online Support,Any problems within validity all free

-

Application:

-

Iron, steel, alloy, aluminum or metal product

-

Precision:

-

0.011 High Precision Machine,Automatic Servo spindle

Quick Details

-

Type:

-

Horizontal

-

Max. Length of Workpiece (mm):

-

450

-

Year:

-

2022

-

Max. Spindle Speed (r.p.m):

-

4500 r.p.m

-

Max. Weight of Workpiece(kg):

-

1000

-

Spindle Bore(mm):

-

62mm or 87mm

-

Width of bed (mm):

-

300 mm

-

Spindle Motor Power(kW):

-

7.5

-

Max. Turned Length (mm):

-

450

-

Travel (X Axis)(mm):

-

160 mm

-

Travel (Z Axis)(mm):

-

500 mm

-

Positioning Accuracy (mm):

-

0.011

-

Repeatability (X/Y/Z) (mm):

-

0.004

-

Place of Origin:

-

Liaoning, China

-

Dimension(L*W*H):

-

2850*3000*18000MM

-

Brand Name:

-

DMTG

-

Model Number:

-

CLS20

-

Voltage:

-

220v/380v

-

Weight (KG):

-

4000

-

Marketing Type:

-

Hot Product

-

Product name:

-

DMTG Lathe Machine

-

Machine Type:

-

Cnc Slant Bed Lathe Machine

-

Function:

-

Boring Machine Turning Milling Drilling Threading Cutting Machine

-

Key word:

-

Metal CNC Turning Lathe Machine High Precision XYZ Axis Lather

-

CNC or Not:

-

CNC Automatic Hydraulic Working Metal Process Lathe Machine

-

Control system:

-

FANUC SIEMENS Mitsubishi GSK(optional)

-

Stock Or not:

-

With Stock And Ready To Ship

-

After-sales:

-

On Site Or Online Support,Any problems within validity all free

-

Application:

-

Iron, steel, alloy, aluminum or metal product

-

Precision:

-

0.011 High Precision Machine,Automatic Servo spindle

CLS20 DMTG Lathe Machine Slant Bed CNC Lathe Machine Metal Turning Process Lathe Machine XYZ Axis Boring Milling Cutting Drilling Lathe Machine

|

CAPACITY

|

Swing over bed

|

mm

|

440

|

|

|

Max. turning length

|

mm

|

450

|

|

|

Max. turning diameter(shaft/disc)

|

mm

|

260/300

|

|

|

Guideway type

|

|

Linear guideway

|

|

SPINDLE

|

Chuck size

|

Inch

|

8

|

|

|

Spindle nose

|

|

ISOA2-6

|

|

|

Spindle bore

|

mm

|

62

|

|

|

Spindle speed

|

rpm

|

4500

|

|

|

Spindle motor power

|

Kw

|

11/15

|

|

|

Spindle torque

|

Nm

|

93/127

|

|

|

Max bar diameter

|

mm

|

51

|

|

TRAVEL

|

X-axis travel

|

mm

|

160

|

|

|

Z-axis travel

|

mm

|

500

|

|

|

X-axis rapid traverse

|

m/min

|

20

|

|

|

Z-axis rapid traverse

|

m/min

|

24

|

|

TOOL POST

|

Turret type and tool number

|

|

Hydraulic 8-station turret

|

|

|

Tool shank size

|

mm

|

25x25

|

|

|

Indexing time(adjacent/farthest)

|

s

|

0.45/1.2

|

|

TAILSTOCK

|

Diameter of tailstock quill

|

mm

|

80

|

|

|

Tailstock quill travel

|

mm

|

130

|

FAQ

1. Is your company a factory or trading company ?

We are factory .

2. What is your payment terms ?

If with stock ,100% payment in advance first,because the machine can ready to ship.

if without stock ,normal 30% down-payment after contract ,and 70% payment before shipment, Meanwhite it can be discussed according to your situation.

3. What is your delivery time ?

The delivery depends on different machines with different configurations. Please contact us to confirm it is in stock or not.

4. What is the warranty period ?

The machine is warranted for a period of 13 months after B/L date or 12 months from the date of ship arrival, whichever is earlier, against faulty workmanship and defective material. In this situation, parts will be supplied for free in replacement of defective parts against detailed inspection report after checkup and ratification.

5. Can you send the service engineer to our company ?

When the machine arrive the destination, we timely send service engineers to install machine according to buyer's schedule, the buyer shall bear all expenses.

Hot Searches