Coasre Grits:

40, 60, 80, 100, 120, 140

Fine Grits:

180, 220, 240, 280, 320, 400, 600, 800, 1200

Original:

CN

Both Coarse grit and fine grit are available for rough sharpening and finish sharpening and grinding. From

- Product Details

- {{item.text}}

Quick Details

-

Size:

-

6", 8"

-

Place of Origin:

-

China

-

Brand Name:

-

RZ

-

Model Number:

-

1A1

-

Viscosity:

-

standard

-

Product name:

-

diamond sharpening wheels

-

Usage:

-

Electroplated wheels for woodturning tools

-

Material:

-

diamond,CBN

-

Bond:

-

metal resin electroplated

-

Color:

-

red yellow brown green black

-

Applicable machine:

-

woodworking tools lathe

-

Applicable Grinder Brand:

-

Rikon, Rockler, Jet, WEN

-

Applicable Tool Material:

-

Carbon Steel, M2 Steel, M42 Steel, HSS steel

Quick Details

-

Application:

-

Aluminum, Deburring

-

Shape:

-

Flat-Shaped

-

Hardness:

-

standard

-

Size:

-

6", 8"

-

Place of Origin:

-

China

-

Brand Name:

-

RZ

-

Model Number:

-

1A1

-

Viscosity:

-

standard

-

Product name:

-

diamond sharpening wheels

-

Usage:

-

Electroplated wheels for woodturning tools

-

Material:

-

diamond,CBN

-

Bond:

-

metal resin electroplated

-

Color:

-

red yellow brown green black

-

Applicable machine:

-

woodworking tools lathe

-

Applicable Grinder Brand:

-

Rikon, Rockler, Jet, WEN

-

Applicable Tool Material:

-

Carbon Steel, M2 Steel, M42 Steel, HSS steel

Products Description

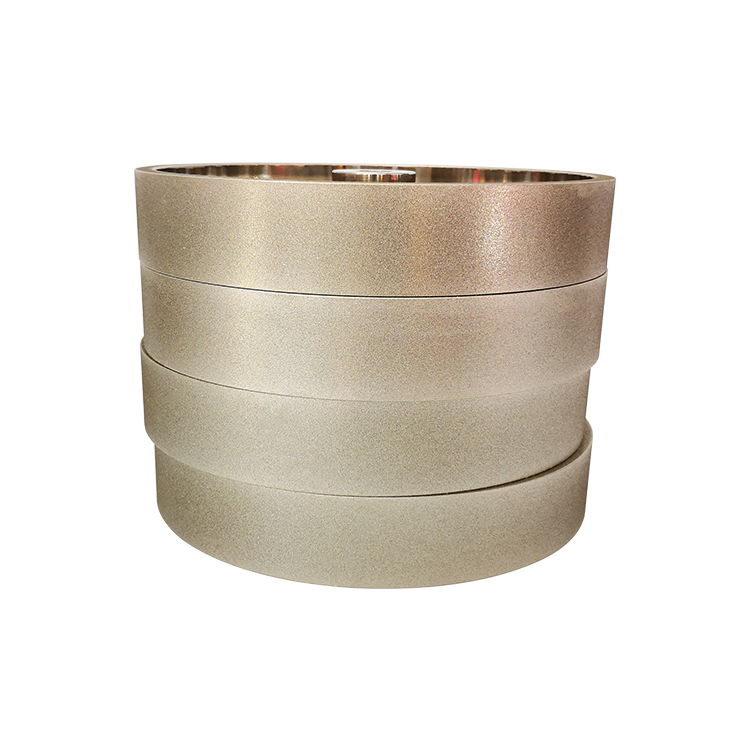

Electroplated wheels for woodturning tools chisel set gouge CBN diamond grinding sharpening wheels discs

1A1 Electroplated Diamond CBN Wheel is made of Steel / Aluminum and Diamond Brasives. We use advanced electroplating process to coat diamond abasives on Steel or Aluminum hubs. Selected diamond abrasives and Solid steel rods and aluminum rods are applied in our products. It makes our products performing well on the quality and appearance. Our customers like its performance and are distrtibuting our products to worldwide markets, such as USA, CANADA, AUSTRAILIA, NEWZEALAND, GERMANY, FRANCE, UK, POLAND, NETHERLAND, SWEDEN, Southeast Asia, and South America. They find good application in Lapidary polishing and grinding, Gemstone polishing and grinding, Stone and marble grinding and polishing, Glass grinding and polishing, Tungsten Carbide grinding, Drill bits sharpening, Endmill Sharpening, Saw Sharpening, Woodworking tool sharpening and many others.

|

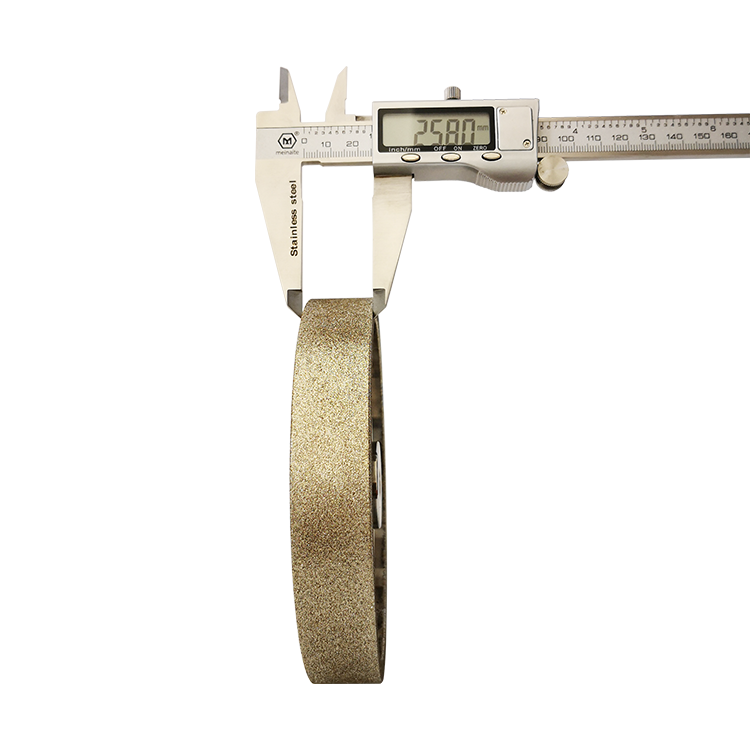

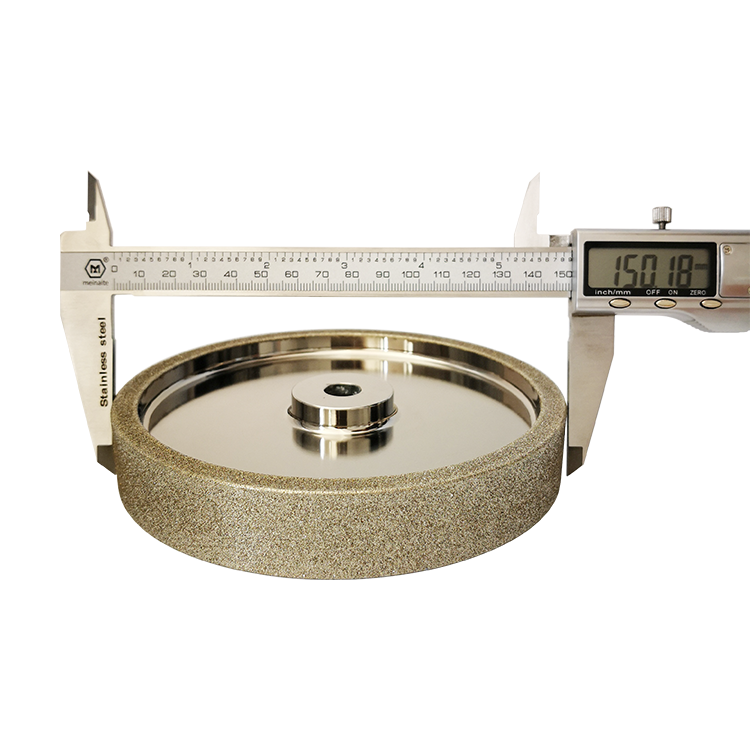

SPECIFICATIONS of 1A1 Diamond Grinding Wheels

|

|

|

|

|||

|

Popular Sizes DxTxH |

6"x1"x1/2" 150x25.4x12.7mm

Grit: 60 to 1200

|

6"x1.5"x1/2" 150x38.1x12.7mm

Grit: 60 to 1200

|

6"x2"x1/2" 150x50x12.7mm

Grit: 60 to 1200

|

|||

|

|

8"x1"x5/8"(1") 200x25.4x15.875mm Grit: 60 to 1200

|

8"x1.5"x1.25" 200x40x31.75mm

Grit: 60 to 1200 |

8"x2"x1.25" 200x50x31.75mm

Grit: 60 to 1200

|

|||

|

|

10"x1"x12mm 250x25.4x12mm

Grit: 60 to 1200

|

10"x1.5"x12mm 250x40x12mm

Grit: 60 to 1200

|

10"x2"x12mm 250x50x12mm

Grit: 60 to 1200

|

|||

|

Typical Grinders |

Bench Grinder

|

Drill Sharpener

|

Saw Sharpener

|

|||

|

|

Tormek

|

Darex

|

Vollmer

|

|||

|

|

Valmarco

|

GSC

|

Loroch

|

|||

|

Application |

Lapidary polishing and grinding

|

Gemstone polishing and grinding

|

Glass grinding and polishing

|

|||

|

|

Stone and marble grinding and polishing

|

Tungsten Carbide grinding and sharpening

|

Drill bits sharpening

|

|||

|

|

Endmill Sharpening

|

Saw Sharpening

|

Woodworking tool sharpening

|

|||

Product Features.

1) Sharp. Fast grinding and fast sharpneing your tools

2) Long life. Much longer life than traditional abrasive wheels

3) Well balanced each wheels.

4) Outter diameter is no change from start to end

5) No dust coming out when sharpening and grinding

2) Long life. Much longer life than traditional abrasive wheels

3) Well balanced each wheels.

4) Outter diameter is no change from start to end

5) No dust coming out when sharpening and grinding

Applications

Diamond grinding wheel has the characteristics of high hardness, high compressive strength, good wear resistance and long service life. It is mainly used in grinding hard and brittle materials and metal materials such as cemented carbide, glass, ceramics and semiconductor materials.

Applicable Machine Brand:

Rikon, Rockler, Jet, WEN.

Applicable Tool Material : Carbon Steel, M2 Steel, M42 Steel, HSS steel.

Applicable Tool Material : Carbon Steel, M2 Steel, M42 Steel, HSS steel.

Selection of grinding wheel elements.

1.hard grinding material, choose the soft, fine grit grinding wheel. Soft grinding material, should choose a hard, coarse grit

grinding wheel. By doing this ,grinding wheel loss is small, also not easy to plug.

2. when doing the rough grinding ,in order to increase the productivity, the coarse grit, soft grinding wheel should be chosen,In order to improve the surface quality of the work piece during accurate grinding , the fine grit ,hard grinding wheel should be chosen.

3.the large area of grinding or thin-walled work piece grinding should choose the coarse grit, soft grinding wheel. This wheel is not easy to plug, the surface of the work piece is not easy to burn, the work piece is not easy to deformation.

4. form grinding process to select the fine grit, the small organization, and the hard grinding wheel to maintain the profile of

the grinding wheel.

grinding wheel. By doing this ,grinding wheel loss is small, also not easy to plug.

2. when doing the rough grinding ,in order to increase the productivity, the coarse grit, soft grinding wheel should be chosen,In order to improve the surface quality of the work piece during accurate grinding , the fine grit ,hard grinding wheel should be chosen.

3.the large area of grinding or thin-walled work piece grinding should choose the coarse grit, soft grinding wheel. This wheel is not easy to plug, the surface of the work piece is not easy to burn, the work piece is not easy to deformation.

4. form grinding process to select the fine grit, the small organization, and the hard grinding wheel to maintain the profile of

the grinding wheel.

Relative products

Detailed Image

Diamond Grits

Balancing

Name:

Dynamic Balancing each wheel

Method: drill off materials to balance the wheel

Results: less than 0.3g

Balance each wheels and control it less than 0.3g.

Method: drill off materials to balance the wheel

Results: less than 0.3g

Balance each wheels and control it less than 0.3g.

Diamond Abrasive

Name:

Synthetic Diamond Abrasives

Type: Selected diamond abrasive to blance the sharpness and the life

Original: CN

Selected Diamond Abrasives, excellent performing on elctroplating diamond products, keep the wheel sharp and last longer.

Type: Selected diamond abrasive to blance the sharpness and the life

Original: CN

Selected Diamond Abrasives, excellent performing on elctroplating diamond products, keep the wheel sharp and last longer.

Core Materials

Steel:

Solid Steel Rods

Aluminum: Solid Aluminum Rods

Selected solid Steel and aluminum rods and well lathed to the precise profile of wheel. Strict tolerances of the bore makes our

wheel always suit your shaft perfectly and not vibrate on your ginder.

Aluminum: Solid Aluminum Rods

Selected solid Steel and aluminum rods and well lathed to the precise profile of wheel. Strict tolerances of the bore makes our

wheel always suit your shaft perfectly and not vibrate on your ginder.

Customer Reviews

Hot Searches