- Product Details

- {{item.text}}

Quick Details

-

Ejector Force(kN):

-

70 kN

-

Theoretical Shot Volume(cm³):

-

805 cm³

-

Injection Rate (g/s):

-

266 g/s

-

Injection Weight (g):

-

732 g

-

Screw diameter (mm):

-

60 mm

-

Weight (KG):

-

8800

-

Place of Origin:

-

Ningbo

-

Open Stroke(mm):

-

590 mm

-

Power (kW):

-

55 kW

-

Product name:

-

China Highshine High Precision Disposable Syringe Making Machine

-

Marketing Type:

-

Hot Sale 2021

Quick Details

-

Distance between Tie Bars(Width)(mm):

-

620mm

-

Distance between Tie Bars(Height)(mm):

-

620mm

-

Ejector Stroke(mm):

-

135 mm

-

Ejector Force(kN):

-

70 kN

-

Theoretical Shot Volume(cm³):

-

805 cm³

-

Injection Rate (g/s):

-

266 g/s

-

Injection Weight (g):

-

732 g

-

Screw diameter (mm):

-

60 mm

-

Weight (KG):

-

8800

-

Place of Origin:

-

Ningbo

-

Open Stroke(mm):

-

590 mm

-

Power (kW):

-

55 kW

-

Product name:

-

China Highshine High Precision Disposable Syringe Making Machine

-

Marketing Type:

-

Hot Sale 2021

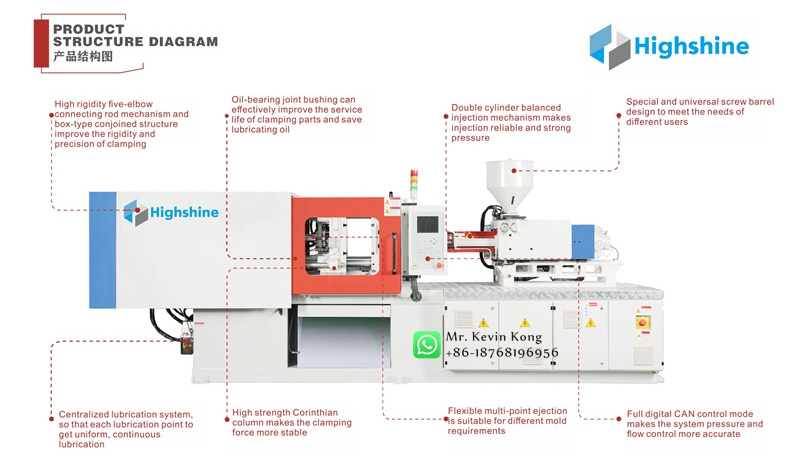

Contact: Mr. Kevin Kong

Mobile&WhatsApp&Wechat: +86-18768196956

|

HIGHSHINE

HS INJECTION MOLDING MACHINE |

|||

| Model List |

Clamping

Tonnage |

Distance Between

Tie Bar (HxV) |

Shot weight

(gram) B SCREW |

| UNIT | ton | mm | g |

| HS120 | 120 | 370X370 | 175 |

| HS140 | 140 | 420X420 | 217 |

| HS158 | 158 | 470X420 | 226 |

| HS170 | 170 | 470X470 | 325 |

| HS230 | 230 | 520X520 | 450 |

| HS270 | 270 | 580X580 | 670 |

| HS300 | 300 | 620X620 | 732 |

| HS330 | 330 | 660X660 | 1000 |

| HS400 | 400 | 730X730 | 1250 |

| HS470 | 470 | 770X770 | 1567 |

| HS530 | 530 | 820X780 | 2200 |

| HS600 | 600 | 875X875 | 2579 |

| HS650 | 650 | 925X875 | 2774 |

| HS780 | 780 | 980X950 | 2901 |

| HS1080 | 1080 | 1125X1085 | 717 |

| HS1250 | 1250 | 1180X1100 | 1125 |

| HS1600 | 1600 | 1500X1350 | 1302 |

We are an enterprise full of vitality, inspiring its creativity and courage everyday; we always will be an enterprise that grows with steady, stepping consistently towards our great vision everyday; we always will be an enterprise that keeps surmounting itself, facing all challenges with brand new status everyday.

Super Energy Saving

40% more energy efficient than the variable pump system. 60% energy saving than the fixed pump + fixed speed motor (depending on the product can not save energy)

High Precision, High Response

The high-precision, high-sensitivity pressure sensor and rotary encoder realize closed-loop control of pressure and flow, and the repeat progress error is less than 1%. The servo motor reaches the maximum output power in only 0.05 seconds.

Low Noise

The noise value is within 78 db. When the machine is not operating, the servo motor stops almost no noise.

Save Cooling Water

Overflow heating of the non-quantitative pump + fixed speed motor system. Low temperature of hydraulic oil, greatly reducing the amount of cooling water

New Clamping Structure

The involute five-point elbow type clamping mechanism, the connecting rod and template of the cast-connected structure strengthened by finite element analysis effectively reduce the stress and deformation, and improve the rigidity and precision of the clamping part

New Power Composition

The servo motor, servo drive, pressure sensor, rotary encoder, gear pump and high-precision injection molding machine special injection molding controller constitute a new power system, so that the energy demand of the injection molding machine is best matched.

Main Applications:

Contact us: