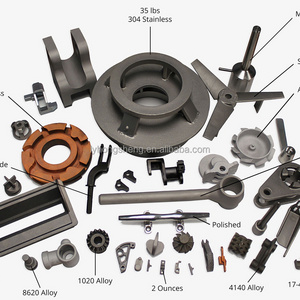

There are a number of different methods available for metal parts manufacturing, investment casting technology is one of the main

process for such metal parts. With the development of investment casting, current investment casting process is more popular for

its advantages, such as low cost, free design, no quantity limitation, etc. So investment casting is always the first choice when

considering a production technology for a product.

- Product Details

- {{item.text}}

Quick Details

-

Material:

-

Stainless steel/alloy steel/carbon steel

-

Certification:

-

ISO9001:2015/AD2000/IATF16949

-

Quality Control:

-

ISO9001 System

-

Product name:

-

Investment casting parts

-

Weight range:

-

0.005kg-100kg

-

Process:

-

lost wax

-

Tolerance:

-

CT6

-

Technology:

-

Silica Sol

-

Package:

-

Wooden Case

-

Service:

-

OEM

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Aleader

-

Model Number:

-

investment casting parts

-

Material:

-

Stainless steel/alloy steel/carbon steel

-

Certification:

-

ISO9001:2015/AD2000/IATF16949

-

Quality Control:

-

ISO9001 System

-

Product name:

-

Investment casting parts

-

Weight range:

-

0.005kg-100kg

-

Process:

-

lost wax

-

Tolerance:

-

CT6

-

Technology:

-

Silica Sol

-

Package:

-

Wooden Case

-

Service:

-

OEM

Product Overview

Investment casting factory

A team full of professional engineers, with 20 years of experience in casting engineers and machining engineers at your service at any time!

FEATURES AT A GLANCE

Our casting capabilities:

Main Products: auto parts, pump & valve parts, impellers, marine hardware, and some other machinery parts.

Application Field: construction industry, chemical machinery, shipbuilding equipment, medical industry, food machinery, and water & wastewater treatment industries,etc.

Main Materials: stainless steel, carbon steel, alloy steel, and brass, etc.

Casting Weight range: 0.005kg-100kg.

Certificate: Supplier verified by TUV, ISO14001, ISO45001, AD2000, IATF16949.

Main Products: auto parts, pump & valve parts, impellers, marine hardware, and some other machinery parts.

Application Field: construction industry, chemical machinery, shipbuilding equipment, medical industry, food machinery, and water & wastewater treatment industries,etc.

Main Materials: stainless steel, carbon steel, alloy steel, and brass, etc.

Casting Weight range: 0.005kg-100kg.

Certificate: Supplier verified by TUV, ISO14001, ISO45001, AD2000, IATF16949.

PRODUCT SPECIFICATIONS

|

Product name

|

Casting parts

|

|

|

|

|||

|

Stainless steel

|

304 316 1.4408 1.4581 410 CF8M SCS24...

|

|

|

|

|||

|

Low alloy steel

|

40Cr 16CrMo4 4140 8630 42CrMo Q235B S45C

|

|

|

|

|||

|

Carbon steel

|

GS45 C15 1.1141 SC410 1.0577...

|

|

|

|

|||

|

Duplex stainless steel

|

2205 1.4517 1.4462 SCS11 1.4468...

|

|

|

|

|||

|

Heat-resistant stainless steel

|

1.4855 1.4776 GX40CrNiSi2512 SCH13 SCH22...

|

|

|

|

|||

|

Process

|

Lost wax

|

|

|

|

|||

|

Min. Wall Thickness

|

1mm

|

|

|

|

|||

|

Min. Radius

|

R0.3

|

|

|

|

|||

|

Casting Roughness

|

Ra3.2-6.3

|

|

|

|

|||

|

Weight range

|

0.005kg-100kg

|

|

|

|

|||

|

Max. Outline Dimension

|

400mm x 500mm x 500mm, single dimensionis no larger than 700mm

|

|

|

|

|||

|

Min. Hole Size

|

Min. Through Hole Diameter 2mm, Max Through Hole depth 4mmMin. Blind Hole Diameter 2mm, Max blind hole depth 2mm

|

|

|

|

|||

|

Casting Tolerance

|

Normally can achieve CT6, best to achieve CT4 as per standard GBT6414-2017

|

|

|

|

|||

|

Certificates

|

ISO9001/TUV/PED/AD2000/IATF16949

|

|

|

|

|||

|

Packing

|

Wooden box or As required

|

|

|

|

|||

Investment Casting Advantages

What Products Can Be Produced by Investment Casting

As one of the oldest casting methods, it services numerous industries. Pls check as followed:

Mechanical Parts

Pump and valve parts

Automotive Parts Casting

Food Processing Casting Parts

Years experience on Investment casting

Don't hesitate to contact us with your drawing. I will reply you at the first time.

SIMILAR PRODUCTS

Right elevation

Left elevation

Front elevation

Packing&Delievery

PRODUCT CONFIGURATION

ISO 9001:2015

ISO 14001:2015

IATF 16949

ISO 45001:2018

AD 2000-EN

AD 2000-DE

Quality Control

100% inspection

We have high-tech equipment and multiple inspections to ensure your products are flawless.

FAQ

Q1:Are you a trading company or manufacturer?Manufacturer with more than 35+ years of experience.

Q2:What are the payment terms?

T/T ( L/C, Paypal, Western Union, and credit card are also available)

Q3: How long is your lead time?

Tooling Lead Times 2 to 4 weeks, less than 20 days for as Cast Parts,

Average Lead Time less than 7 weeks

Q4: Do you accept OEM service and can you produce according to our drawings?

Yes, we do. We have a professional engineer department to design products according to your

samples or drawings.

Q5: May I have a free sample before ordering?

Sure, please contact me to confirm when and how to deliver the samples.

Q2:What are the payment terms?

T/T ( L/C, Paypal, Western Union, and credit card are also available)

Q3: How long is your lead time?

Tooling Lead Times 2 to 4 weeks, less than 20 days for as Cast Parts,

Average Lead Time less than 7 weeks

Q4: Do you accept OEM service and can you produce according to our drawings?

Yes, we do. We have a professional engineer department to design products according to your

samples or drawings.

Q5: May I have a free sample before ordering?

Sure, please contact me to confirm when and how to deliver the samples.

Hot Searches