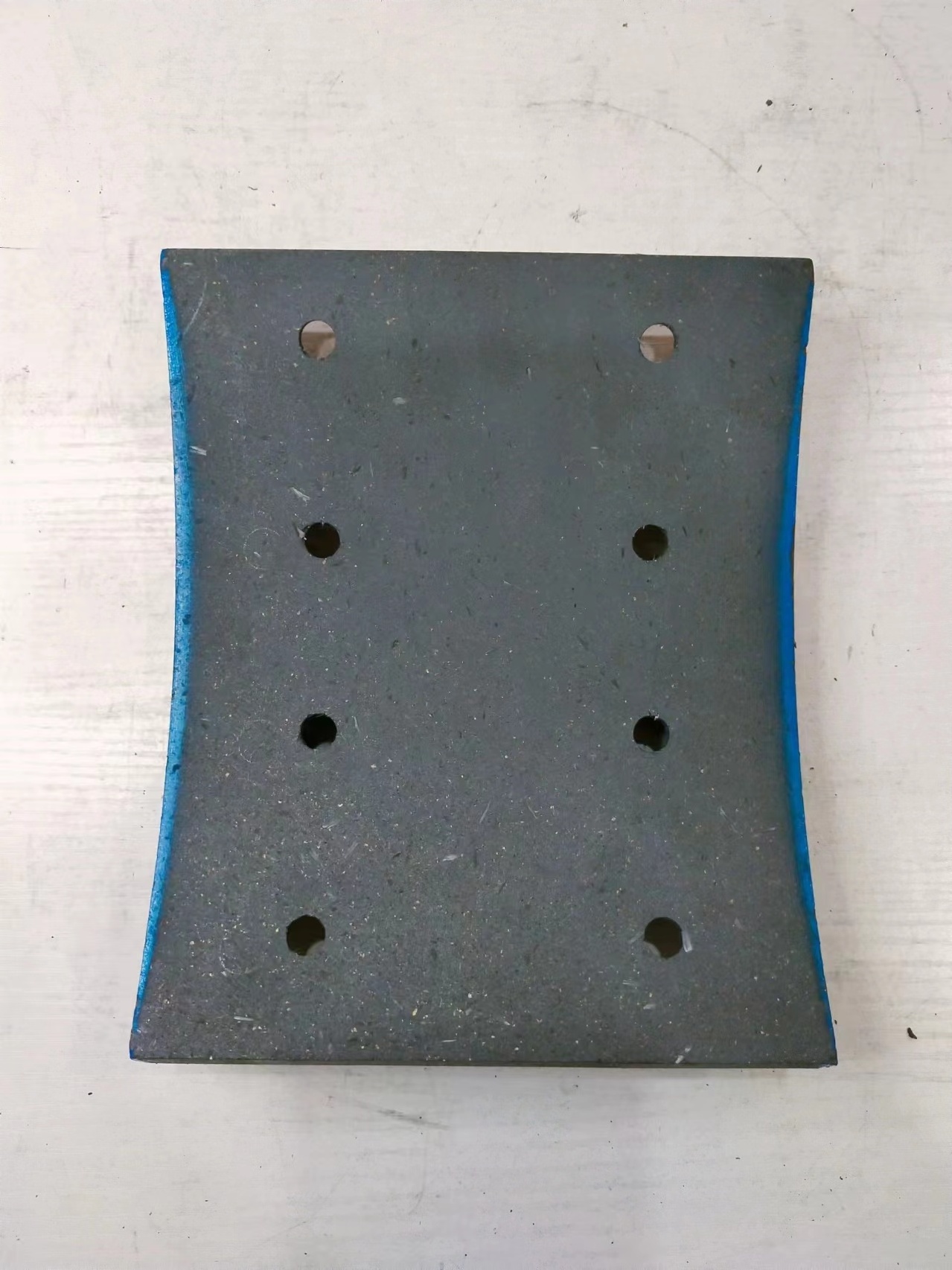

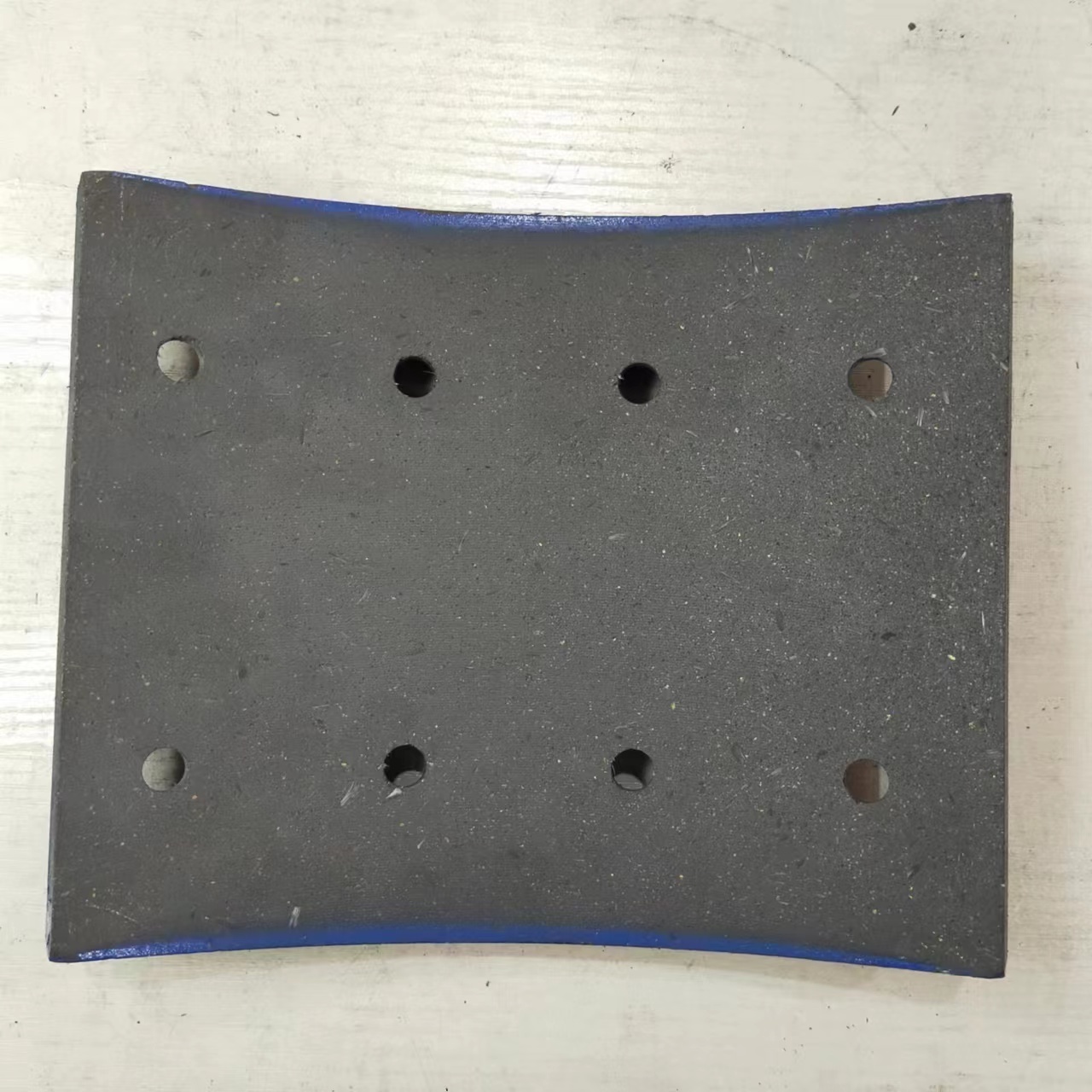

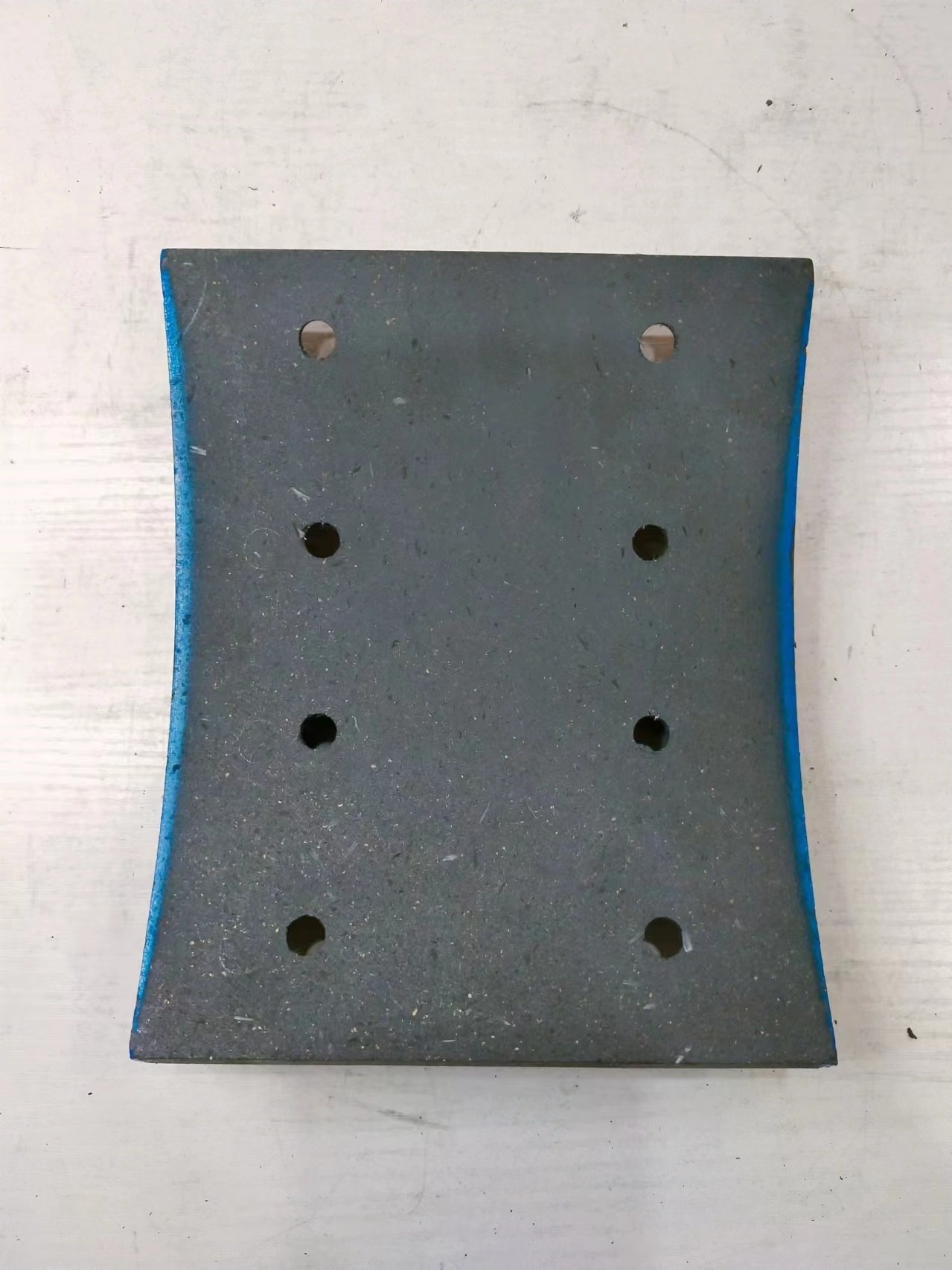

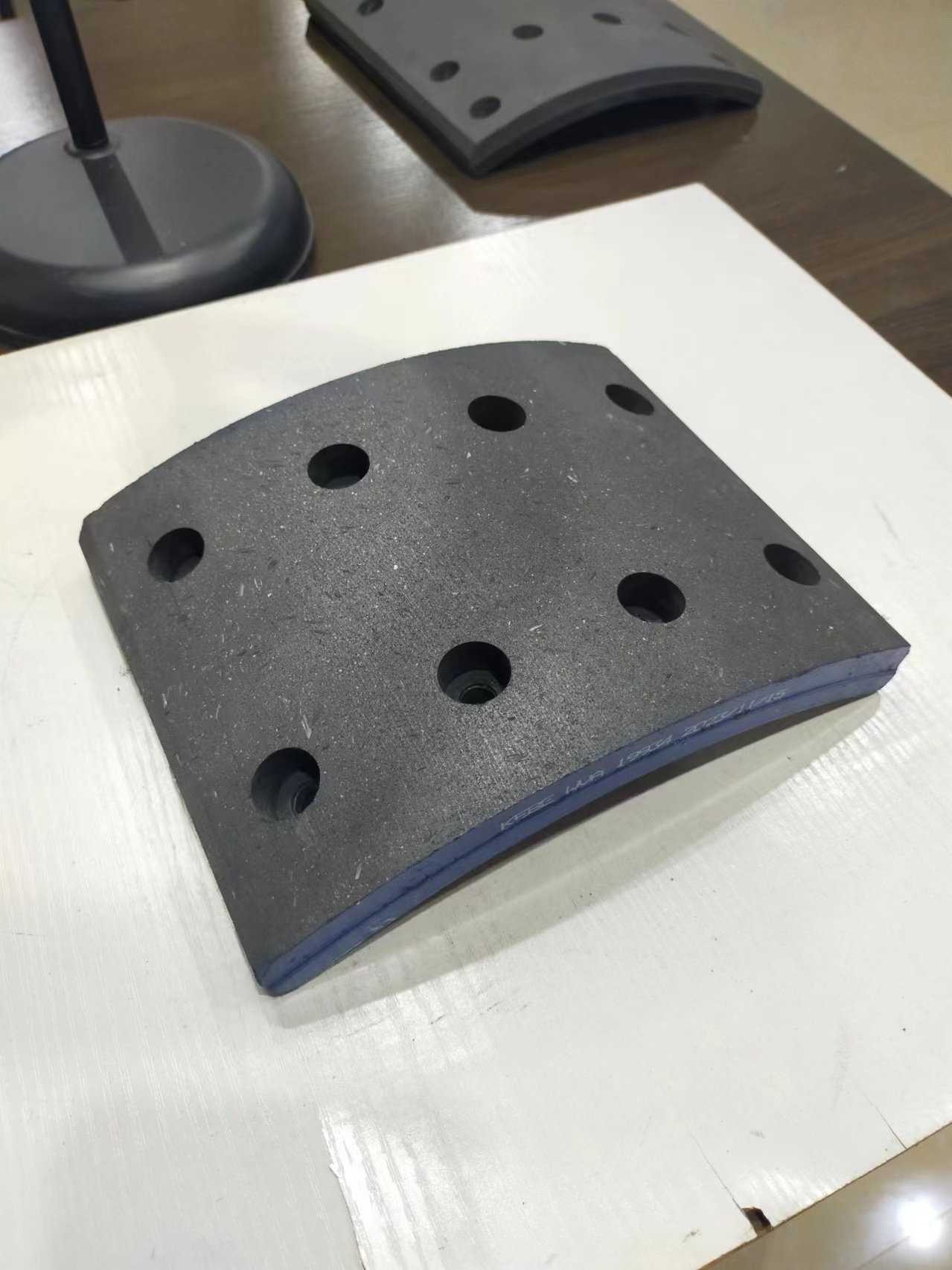

the asbestos-free brake pad material is stable, the friction coefficient is uniform, and it is relatively quiet during braking.

- Product Details

- {{item.text}}

Quick Details

-

Warranty:

-

1 year

-

Place of Origin:

-

Hubei, China

-

Brand Name:

-

Longyun

-

Car Model:

-

Master II Kasten

-

Size:

-

195*150*18 mm

-

Product Name:

-

Brake Pads

-

Brand:

-

Longyun

-

MOQ:

-

50 Sets

-

Certification:

-

ISO9001/TS16949

-

OEM:

-

Available

-

SAMPLE:

-

Available

-

Application:

-

Master II Kasten

-

Quality:

-

100% Tested

-

Guarantee:

-

60000~80000km

Quick Details

-

OE NO.:

-

5000812335

-

Reference NO.:

-

1993410; 420023; 81419; AA93020

-

Material:

-

non asbestos, Non asbestos ceramic, Non-asbestos carbon fiber

-

Warranty:

-

1 year

-

Place of Origin:

-

Hubei, China

-

Brand Name:

-

Longyun

-

Car Model:

-

Master II Kasten

-

Size:

-

195*150*18 mm

-

Product Name:

-

Brake Pads

-

Brand:

-

Longyun

-

MOQ:

-

50 Sets

-

Certification:

-

ISO9001/TS16949

-

OEM:

-

Available

-

SAMPLE:

-

Available

-

Application:

-

Master II Kasten

-

Quality:

-

100% Tested

-

Guarantee:

-

60000~80000km

|

Temperature℃

|

100

|

200

|

300

|

350

|

|

Specified Friction Coefficient

|

0.36

|

0.36

|

0.36

|

0.36

|

|

Allowable Deviation

|

±0.08

|

±0.10

|

±0.12

|

±0.14

|

|

Wear rate

|

≤0.25

|

≤0.45

|

≤0.75

|

≤0.85

|

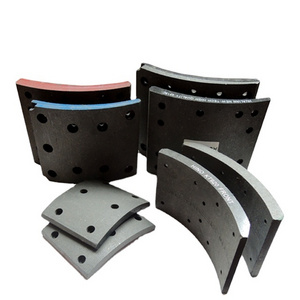

Automobile brake pads refer to the friction material fixed on the brake drum or brake disc that rotates with the wheel. The friction plates and friction pads are subjected to external pressure to generate friction, thereby achieving the purpose of decelerating the vehicle. Our brake pads are asbestos free brake pads. Asbestos-free brake pads have the characteristics of low noise, safety and environmental protection, stability and reliability.

Our brake pads have three great features: First of all, it has a self-increasing force effect and a large braking force. Secondly, our brake pads are easy to integrate into the handbrake. Last but not least, our brake pads are long lasting and affordable.

.

Brake lining production process:

Raw material mixing

Basically the brake skin is composed of steel fiber, mineral wool, foundation, wear-resistant agent, resin and other chemicals, and the friction coefficient wear-resistant index and noise value are adjusted through the proportion distribution of these raw materials.

Hot forming stage

Pour the mixed raw materials into the mold, and pressure molding

Plate treatment

according to different models of iron village after cutting, but also need to pass bead to the surface hardening treatment, in order to glue ready to stick on the brake prototype.

Hot pressing stage

The use of mechanical plate and brake pads high heat pressure, so that the two can be more closely combined, and the manufactured product is called Brake Rough Embryo

Heat treatment stage

In order to make the brake pad village mass energy more stable, heat resistance more painful, so it is necessary to penetrate the heat treatment, the brake rough embryo heating for more than 6 hours, in order to continue processing.

Grinding and Cutting Stage

After heat treatment of the brake pads, the surface still needs to be hairy, so it needs to be polished and cut to be smooth

Product Introduction

|

Product Name

|

Brake

|

|

|

|

|||

|

Brand Name

|

Longyun

|

|

|

|

|||

|

Material

|

Non asbestos ceramic, Non-asbestos carbon fiber

|

|

|

|

|||

|

Place of Origin

|

China

|

|

|

|

|||

|

Car Model

|

Renault Magnum Manager

|

|

|

|

|||

|

Size

|

195*150*18 mm

|

|

|

|

|||

|

Warranty

|

Six Month

|

|

|

|

|||

|

Certification

|

ISO9001/TS16949

|

|

|

|

|||

|

MOQ

|

50 Sets

|

|

|

|

|||

|

Packing

|

Neutral box

|

|

|

|

|||

|

Delivery TIME

|

7~10 Days

|

|

|

|

|||

We are your best option

State-of-the-art equipment

We have advanced mixing systems, heat pressing systems, and most importantly, a complete testing system to ensure that all products

have perfect quality.

have perfect quality.

High Quality Raw Materials

We have adopted German technology and developed over a hundred formulas to meet the demands of different types of vehicles.

Quality Control

We have a rigorous quality control system in place,we ensure that all products meet the requirements of our customers.

Features

Low noise

Safety and environmental protection

Asbestos-free brake pads do not contain asbestos, lead and other harmful substances, making them safer and more environmentally

friendly to use.

friendly to use.

Stable and reliable

Asbestos-free brake pads are made of non-asbestos organic composite materials, with stable friction coefficient and long service

life.

life.

Product management

Products : Automotive Disc Brake Pads

Drum brake pads should be replaced every 50,000-80,000 kilometers. Brake pads are wearing parts, so pay special attention to them. However, you can determine the brake pad replacement cycle based on your driving habits. Generally speaking, vehicle brake pads need to be replaced when their thickness is worn to one-third of their original value. Failure to replace the brake pads in time will cause the vehicle to lose control and affect driving safety.

Product specifications

Products : Automotive Disc Brake Pads

Our company is engaged in professional brake pad production. During the production process, certified raw materials, latest technology and 100% quality control are used. As a brake pad manufacturer, we pay close attention to quality and production. Our products are non asbestos ceramic and non asbestos carbon fiber.

Packaging & Delivery

●

We are professional in production of brake lining as well as packing and shipping.

●

We usually use

neutral packing

, also can be

customized according to your requirements

.

Hot Searches