1) High recovery ratio;

2) High concentration ratio;

3) Easy installation;

4) Simple operation;

5) Deck constructed of fiber glass;

6) Seven different decks to choose;

7) Long working life;

8) Adjustable stroke length and speed.

- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

3000*1620*1100

-

Weight:

-

150 KG

-

Square meter(M2):

-

4.08

-

Feed size(mm) Coarse sand:

-

1-2.5

-

Feed size(mm) Fine sand:

-

0.8-1.2

-

Feed size(mm) Mud:

-

0.3-0.9

-

Water consumption(t/h):

-

0.4-1.8

-

Stoke(mm):

-

10-30

Quick Details

-

Production Capacity:

-

90%

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

keda

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

3000*1620*1100

-

Weight:

-

150 KG

-

Square meter(M2):

-

4.08

-

Feed size(mm) Coarse sand:

-

1-2.5

-

Feed size(mm) Fine sand:

-

0.8-1.2

-

Feed size(mm) Mud:

-

0.3-0.9

-

Water consumption(t/h):

-

0.4-1.8

-

Stoke(mm):

-

10-30

Product Overview

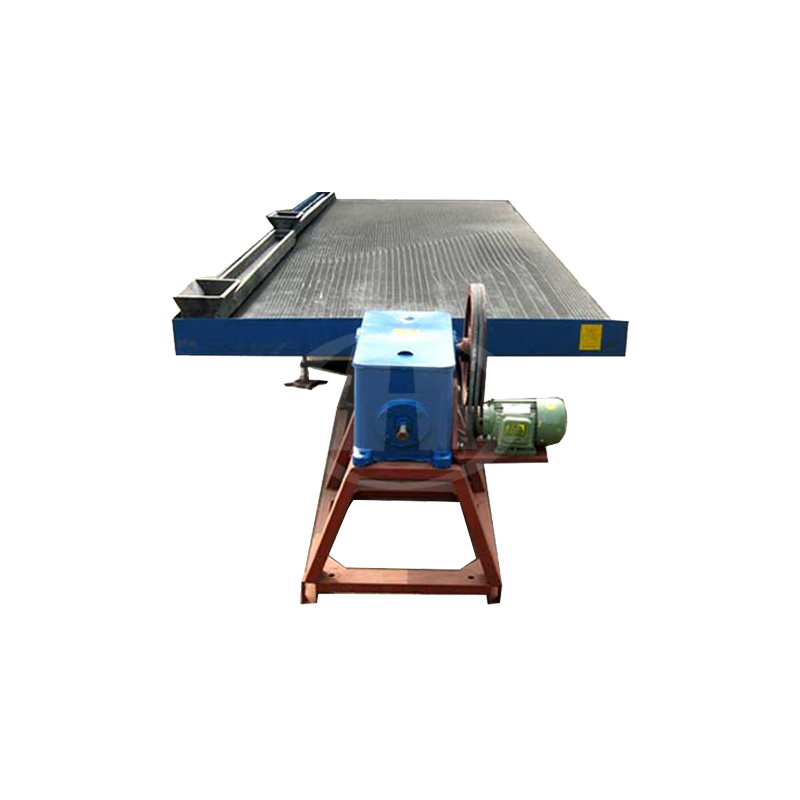

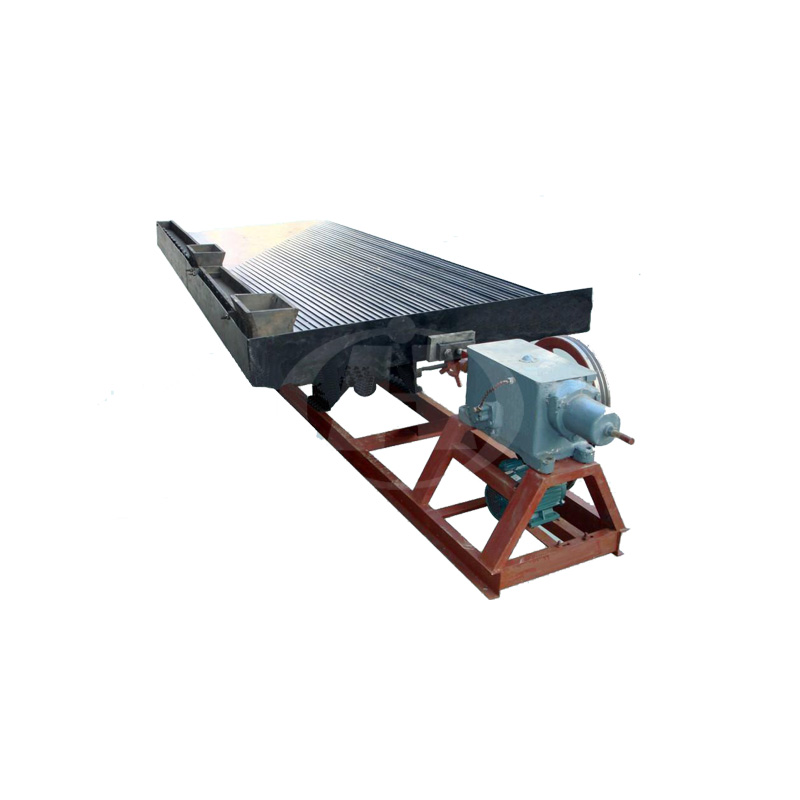

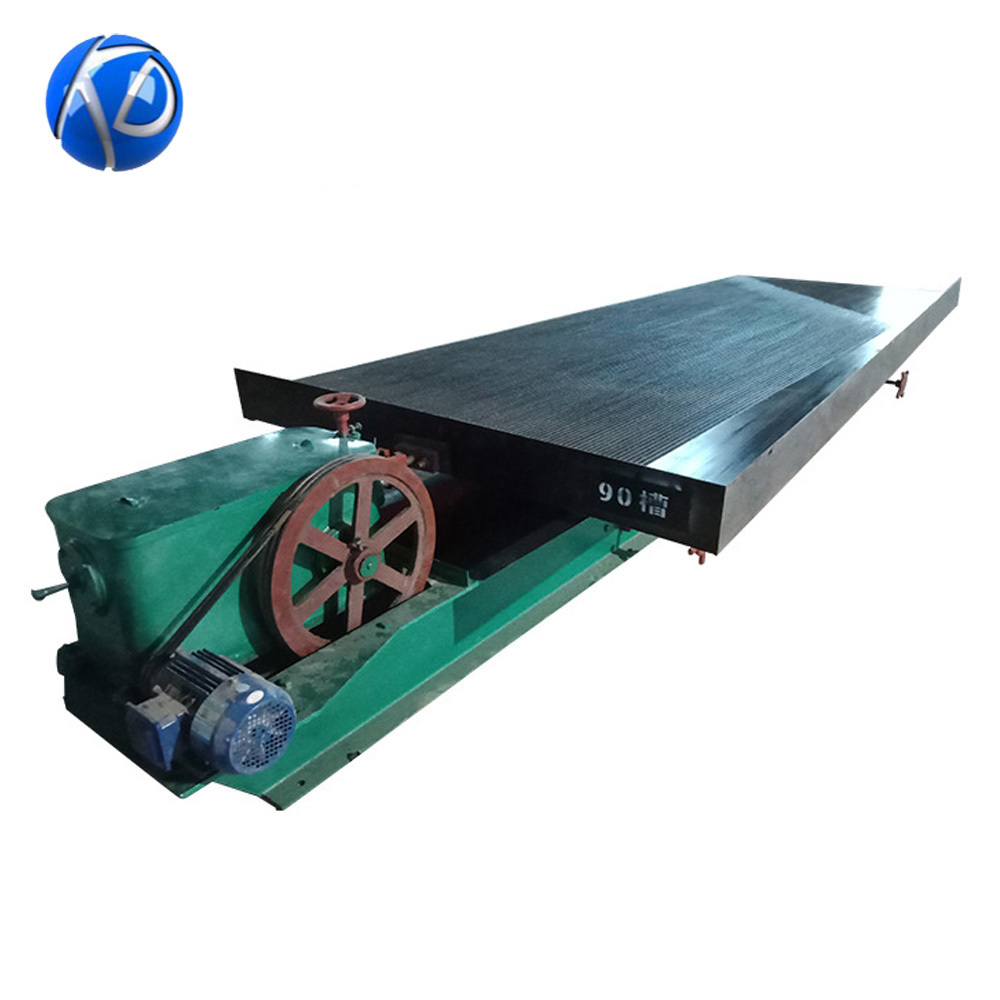

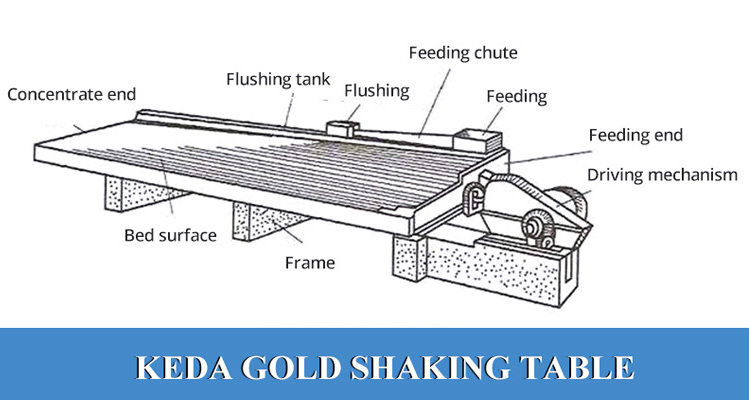

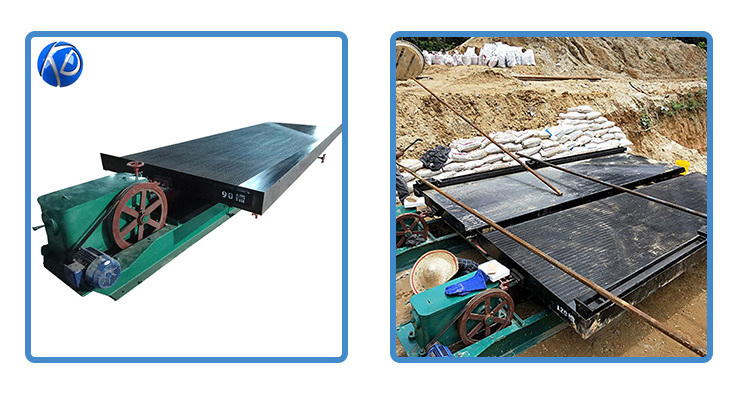

Gold Panning Equipment 6-S Gold Mining Shaking Table

Shaking table is also called table concentrator, is a mine separation device for fine minerals working by gravity.

As per different minerals have different density, Shaking table is effective in processing precious and base metal, rare metal and non-metallic minerals, widely used in separation for Gold, Copper, Silver, Tin, Columbium, Tantalum, Titanium, Barium, Tungsten, Iron, Chrome, Manganese, Zircon, Rutile, Ilmenite, Lead, Zinc, Mercury, Copper, Aluminum, etc.

The shaker effective recycling granularity scope is 2-0.037 mm.

As per different minerals have different density, Shaking table is effective in processing precious and base metal, rare metal and non-metallic minerals, widely used in separation for Gold, Copper, Silver, Tin, Columbium, Tantalum, Titanium, Barium, Tungsten, Iron, Chrome, Manganese, Zircon, Rutile, Ilmenite, Lead, Zinc, Mercury, Copper, Aluminum, etc.

The shaker effective recycling granularity scope is 2-0.037 mm.

Our Advantages

Details Images

Product parameters

|

Specification

|

|

6-S model

|

6-S model

|

6-S model

|

6-S model

|

|||||

|

Bed model

|

|

LY(S)

|

LY

|

LY

|

LY

|

|||||

|

Bed surface size(mm)

|

|

4500*1850*1560

|

3000*1620*1100

|

2100*1050*850

|

1100*500*430

|

|||||

|

Square meter(M2)

|

|

7.67

|

4.08

|

2

|

0.51

|

|||||

|

Feed size(mm)

|

Coarse sand

|

2-0.5

|

2-0.5

|

2-0.5

|

2-0.5

|

|||||

|

|

Fine sand

|

0.5-0.074

|

0.5-0.074

|

0.5-0.074

|

0.5-0.074

|

|||||

|

|

Mud

|

0.074-0.037

|

0.074-0.037

|

0.074-0.037

|

0.074-0.037

|

|||||

|

Feeding density(%)

|

|

10-30

|

10-30

|

10-30

|

10-30

|

|||||

|

Processing capacity(t/h)

|

Coarse sand

|

1-2.5

|

0.6-1.5

|

0.4-0.8

|

0.1-0.2

|

|||||

|

|

Fine sand

|

0.8-1.2

|

0.3-0.8

|

0.2-0.5

|

0.05-0.1

|

|||||

|

|

Mud

|

0.3-0.9

|

0.2-0.6

|

0.1-0.4

|

0.03-0.05

|

|||||

|

Water consumption(t/h)

|

|

0.4-1.8

|

0.3-1.5

|

0.2-1

|

0.1-0.5

|

|||||

|

Stoke(mm)

|

|

10-30

|

10-30

|

10-30

|

9~17

|

|||||

|

Frequency of stoke(time/min)

|

|

240-360

|

210-360

|

210-360

|

130-210

|

|||||

|

Transverse slope (degree)

|

|

0°~10°

|

0°~10°

|

0°~10°

|

0°~8°

|

|||||

|

Motor

|

Model

|

Y70L-4

|

Y100L-4

|

Y90L-4

|

Y80L-4

|

|||||

|

|

Power(kw)

|

1.1

|

1.1

|

1.1

|

0.55

|

|||||

|

|

Speed(r/min)

|

1400

|

1400

|

1400

|

1400

|

|||||

|

V-belt (mm)

|

|

A-2000

|

A-1033

|

B-2007

|

A-1245

|

|||||

|

L*W*H Dimension(mm)

|

|

5630*1850*900

|

4075*1320*780

|

3040*1050*1020

|

1530*500*800

|

|||||

|

6S shaking table feeding density reference table

|

|

|

|

|

|

|||||

|

Model

|

|

Feeding density(%)

|

|

|

|

|||||

|

|

|

Coarse sand

|

Fine sand

|

Mud

|

|

|||||

|

6S model shaking table

|

|

20-30

|

18-25

|

15-20

|

|

|||||

Our Service

1) Pre-sale service: Freely provide project designing, process designing, select suitable equipment for you.

2) On-sale service: Provide equipment layout draw, foundation draw and detail equipment manauls. Timely report you the

manufacturing schedule and related photos for keep monitoring.

3) After-sales service: Dispatch engineer to the site to guide installation, debugging and training operators. Installation and

operation workers are offered if you need.

2) On-sale service: Provide equipment layout draw, foundation draw and detail equipment manauls. Timely report you the

manufacturing schedule and related photos for keep monitoring.

3) After-sales service: Dispatch engineer to the site to guide installation, debugging and training operators. Installation and

operation workers are offered if you need.

Hot Searches