- Product Details

- {{item.text}}

Quick Details

-

Insulation Material:

-

PVC

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Sinton

-

Model Number:

-

0Cr25AL5

-

sizes:

-

all size available

-

shape:

-

wire or strip

-

hardness:

-

200-260HB

-

MOQ:

-

1kg

-

Name:

-

resistance wire

-

Delivery Time:

-

15 Days

-

Package:

-

Carton

-

Certification:

-

IOS9001, ROHS

-

Grade:

-

Nickel Base Alloy

-

Surface:

-

Bright

Quick Details

-

Application:

-

Heating

-

Conductor Material:

-

Copper

-

Conductor Type:

-

Solid

-

Insulation Material:

-

PVC

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Sinton

-

Model Number:

-

0Cr25AL5

-

sizes:

-

all size available

-

shape:

-

wire or strip

-

hardness:

-

200-260HB

-

MOQ:

-

1kg

-

Name:

-

resistance wire

-

Delivery Time:

-

15 Days

-

Package:

-

Carton

-

Certification:

-

IOS9001, ROHS

-

Grade:

-

Nickel Base Alloy

-

Surface:

-

Bright

Product Description

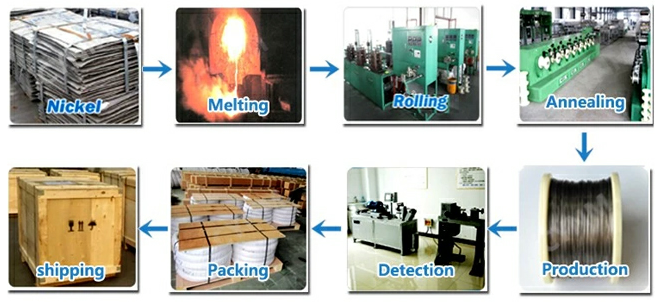

Fe-Cr-Al alloy wires are made of iron chromium aluminum base alloys containing small amounts of reactive elements such as yttrium and zirconium and produced by smelting, steel rolling, forging, annealing, drawing, surface treatment, resistance control test, etc

.

The high aluminum content, in combination with the high chromium content let the scaling temperature can reach to 1425ºC (2600ºF);

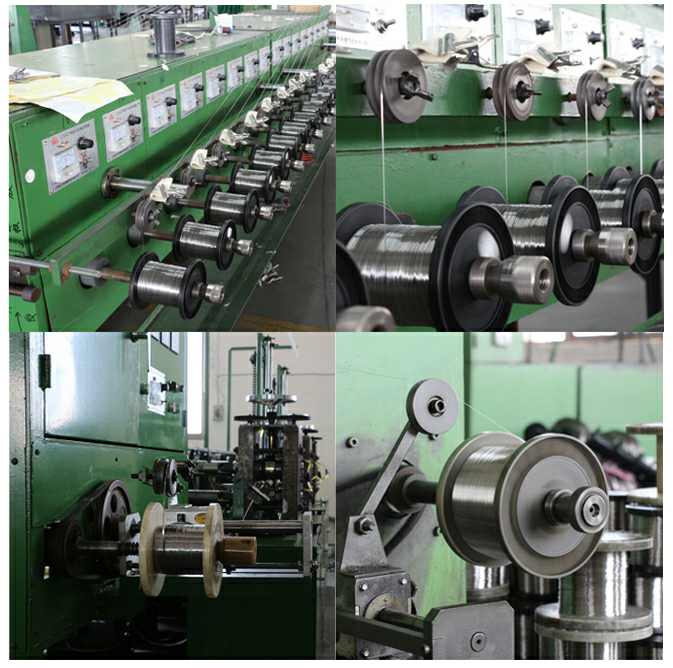

Heating wires shaped by means of high speed automatic cooling machine of which the power capacity is controlled by computer, they are available as wire and ribbon.

The Alloy resistance Heating Wire includes pure nickel, chromium alloy, iron-chromium aluminum alloy and copper-nickel alloy.

Fecral resistance Heating Wire is produced by melting, rolling, forging, annealing, drawing, surface treatment, resistance control

test and other methods.

Fecral resistance Heating Wire is produced by melting, rolling, forging, annealing, drawing, surface treatment, resistance control

test and other methods.

Features

1. High using temperature, the maximum using temperature can reach 1400C (0Cr21A16Nb, 0Cr27A17Mo2, etc.) 2. Low temperature

coefficient of resistance

3. Lower thermal expansion coefficient than the Ni-base super-alloys.

4. High electrical resistivity

5. Good corrosion resistance under high temperature, especially under the atmosphere containing sulfides

6. High surface load

7. Creep-resistant

8. Lower raw-material cost, Lower density and cheaper price compared with Nichrome wire.

9. Superior oxidation resistance at 800-1300ºC

10. Long service life

coefficient of resistance

3. Lower thermal expansion coefficient than the Ni-base super-alloys.

4. High electrical resistivity

5. Good corrosion resistance under high temperature, especially under the atmosphere containing sulfides

6. High surface load

7. Creep-resistant

8. Lower raw-material cost, Lower density and cheaper price compared with Nichrome wire.

9. Superior oxidation resistance at 800-1300ºC

10. Long service life

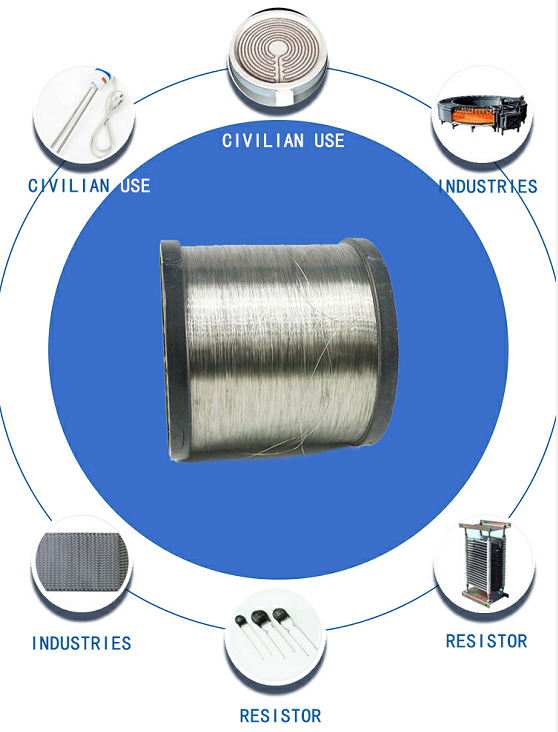

Application Area

Fecral Alloy Cr15Ni60 electric resistance Heating Wire is main widely used in manufacturing industrial furnaces, civil heating equipment, various resistors and locomotive brake resistors and other heating equipment.And Cr15Ni60 electric resistance Heating Wire is also suitable for keeping the car's hot seat and steering wheel warm, refrigerator, air conditioner, USB cable heater for heating, electric blanket, towel, foot massage, electric stove, pet pillow, hot clothes, window heating, plumbing Freeze protection, electric slimming belt, pet incubator, medical care equipment.

Detailed Images

Fecral resistance Heating Wire Size dimension range.

Our main products include two series of iron chromium aluminum and nickel chromium, as well as Fecral Alloy Cr15Ni60 electric resistance Heating Wires of various types and specifications.

Our main products include two series of iron chromium aluminum and nickel chromium, as well as Fecral Alloy Cr15Ni60 electric resistance Heating Wires of various types and specifications.

Wire

: 0.01-10mm

Ribbon : 0.05*0.2-2.0*6.0mm

Strip : 0.05*5.0-5.0*250mm

NiCr series : Cr10Ni90,Cr20Ni80, Cr30Ni70, Cr15Ni60, Cr20Ni35, Cr20Ni30

Ribbon : 0.05*0.2-2.0*6.0mm

Strip : 0.05*5.0-5.0*250mm

NiCr series : Cr10Ni90,Cr20Ni80, Cr30Ni70, Cr15Ni60, Cr20Ni35, Cr20Ni30

|

Alloy Nomenclature Performance

|

|

Cr20Ni80

|

Cr30Ni70

|

Cr15Ni60

|

Cr20Ni35

|

Cr20Ni30

|

|

|

main chemical composition

|

Ni

|

Rest

|

Rest

|

55.0-61.0

|

34.0-37.0

|

30.0-34.0

|

|

|

|

Cr

|

20.0-23.0

|

28.0-31.0

|

15.0-18.0

|

18.0-21.0

|

18.0-21.0

|

|

|

|

Fe

|

≤1.0

|

≤1.0

|

Rest

|

Rest

|

Rest

|

|

|

Max. continuous service temp. of element(ºC)

|

|

1200

|

1250

|

1150

|

1150

|

1150

|

|

|

Meltiing point ℃

|

|

1400

|

1380

|

1390

|

1390

|

1390

|

|

|

Resistivity at 20ºC (μΩ·m)

|

|

1.09±0.05

|

1.18±0.05

|

1.12±0.05

|

1.00±0.05

|

1.04±0.05

|

|

|

Density(g/cm3)

|

|

8.4

|

8.1

|

8.2

|

7.9

|

7.9

|

|

|

Thermal conductivity (KJ/m·h·ºC)

|

|

60.3

|

45.2

|

45.2

|

43.8

|

43.8

|

|

|

Coefficient of lines expansion(α×10-6/ºC)

|

|

18

|

17

|

17

|

19

|

19

|

|

|

Melting point approx.( ºC)

|

|

1400

|

1380

|

1390

|

1390

|

1390

|

|

|

Elongation at rupture(%)

|

|

>20

|

>20

|

>20

|

>20

|

>20

|

|

|

Micrographic structure

|

|

Austenite

|

Austenite

|

Austenite

|

Austenite

|

Austenite

|

|

|

Magnetic properties

|

|

Nonmagnetic

|

Nonmagnetic

|

Nonmagnetic

|

Weak magnetic

|

Weak magnetic

|

|

Certification

Company Introduction

YanCheng XingTai Electric Equipment Co., Ltd. is a integrated company which has been operating with a modern enterprise system and integrating domestic, foreign trade and production and sales. The company chief products and sells various efficient saving-energy and green electric heating equipment products such as cartridge heater; tubular heater; resistance wire;plate heater, coil heater, band heater ; temperature sensor etc. At the same time, if you have any specific requirement, our professional technical team will provide special one-step service that from design to production installation and debugging for you. Due to Xing Tai has been digesting and innovating the most advanced production equipments and technology that has been introducing from foreign, we have won a lot of credit and trust from our broad masses of users. Currently our company enjoys high reputation in the petroleum, chemical, electric power, machinery, installation of the transformation project cooperation in the country. Our production has been sold to Europe, America, southeast Asia, the Middle East and so on. Xing Tai has built a scientific production management, improved the quality management system and after-sale service---the most professional, attentive, intimate.

Packaging & Delivery

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory since 2003 which professional produce resistance alloys and nickel based alloy products.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. Or it is 15-30 days if the goods are not in stock, it accords to order quantity.

Q:Do you provide samples ? is it free or extra ?

A:Yes, we could offer the sample but do not bear the cost of freight.

Q:How would i get in touch with you?

A:We are always ready to service to you. Pls contact me via below info:

Mobile/Whatsapp/Skype: 0086-400-670-9559

Contact Us

Hot Searches