- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

FTM

-

Dimension(L*W*H):

-

1100x1032x1285mm

-

Weight:

-

2800 KG

-

Product name:

-

portable Jaw crusher

-

Max feeding size:

-

210mm

-

Discharge opening:

-

20-60mm

-

Capacity:

-

5-21t/h

-

Rotation speed:

-

300r/min

-

Structure:

-

welding

-

Application material:

-

147-245Mpa rocks

-

Installation:

-

Engineer Guide

-

Spare parts supply:

-

Anytime

-

Color:

-

Customer Requirement

Quick Details

-

Application:

-

mining used

-

Capacity(t/h):

-

1-1000t/h

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

FTM

-

Dimension(L*W*H):

-

1100x1032x1285mm

-

Weight:

-

2800 KG

-

Product name:

-

portable Jaw crusher

-

Max feeding size:

-

210mm

-

Discharge opening:

-

20-60mm

-

Capacity:

-

5-21t/h

-

Rotation speed:

-

300r/min

-

Structure:

-

welding

-

Application material:

-

147-245Mpa rocks

-

Installation:

-

Engineer Guide

-

Spare parts supply:

-

Anytime

-

Color:

-

Customer Requirement

Product Description

Jaw crusher is a primary crusher that is widely used in crushing circuits, providing better crushing solutions for mining, smelting, building materials, highways, railways, water conservancy, chemical industry and other industries. Our jaw crushers can provide you with an excellent crushing experience with excellent quality and performance.

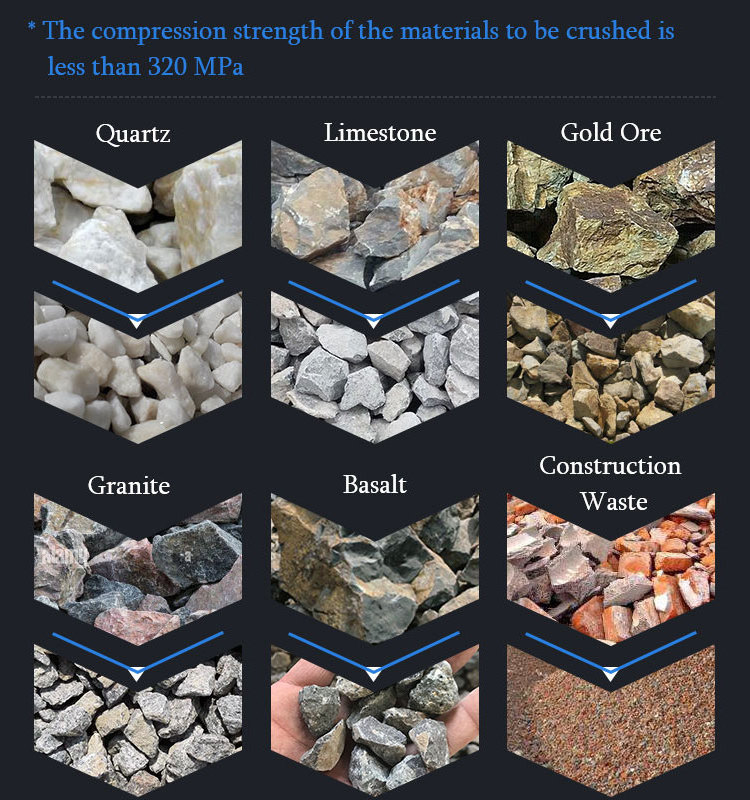

Applicable materials

The compression strength of the materials to be crushed is less than 320 MPa.Whether it is metal ores (gold ore, iron ore, etc.), non-metallic ores (quartz, limestone, gypsum, etc.), rocks (granite, basalt, etc.), gangue, concrete, construction waste , glass, or cement clinker, our jaw crushers can easily crush it.

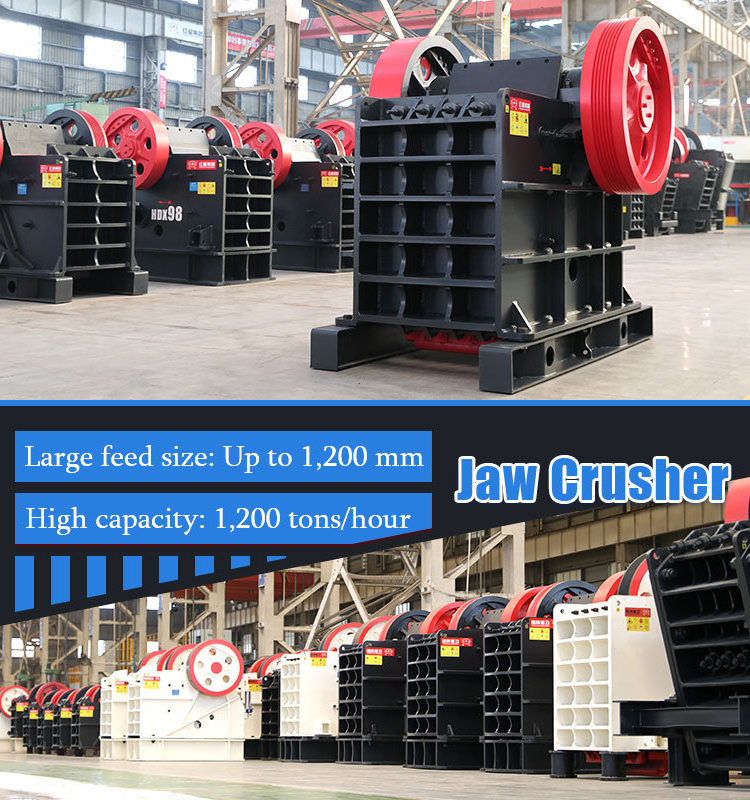

Globally recognized performance

Thousands of jaw crushers produced by us are installed around the world and have demonstrated excellent performance in aggregate crushing, mineral processing and recycling.

- Superior crushing capacity: Large crushing ratio (3-6), uniform output size.

- Large feed size: Up to 1,200 mm.

- High capacity: The capacity can reach 1,200 tons/hour, meeting large-scale crushing needs.

- Capacity: 30-2,000 t/h.

- Low operating cost: The simple structure and optimized performance ensure the increase of output and productivity, and also reduce the cost.

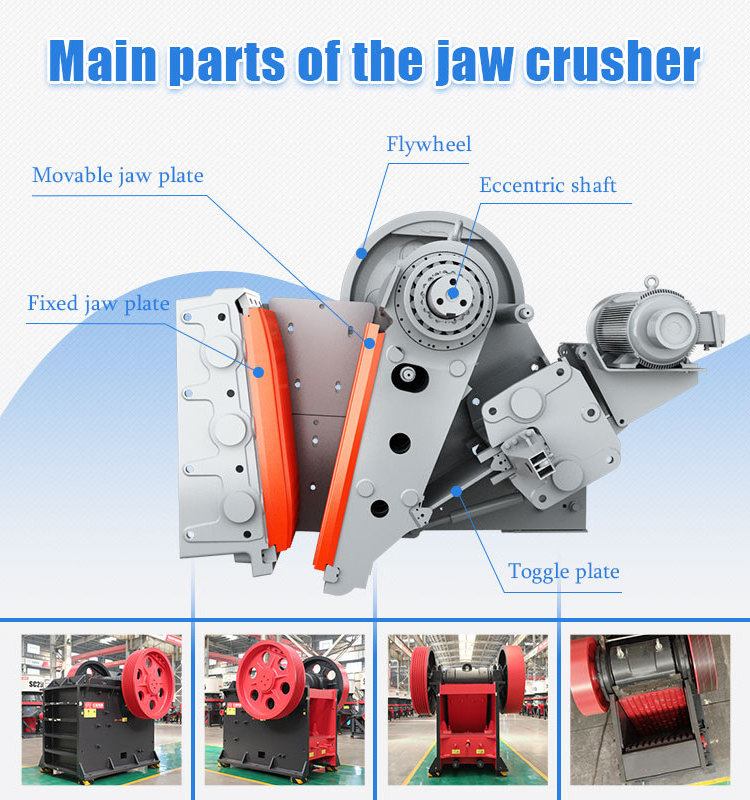

The basic structure of the jaw crusher includes the main frame, fixed jaw plate, movable jaw plate, toggle plate, eccentric shaft, flywheel, etc.

We have engineered each component to maximize its performance and service life:

- The crushing cavity is deep and there are no dead corners, which improves feeding and output.

- Large crushing ratio and uniform particle size.

- Welded fixed steel structure, large bearings, and forged spindle make the bearing capacity better.

- The unique flywheel design effectively reduces vibration and makes the machine run more stably.

- The discharge port can be adjusted within a wide range through gaskets to meet various particle size requirements of customers.

- Simple structure and special centralized lubrication system makes operation and maintenance easier.

- The wearing parts jaw plates (one fixed, one movable) are made of wear-resistant materials (high manganese steel, alloy steel, etc.) to extend the service life.

- Less dust, low noise, and the energy consumption can be reduced by 15%-30%.

Working Principle

The motor drives the belt wheel, and makes movable jaw up and down by eccentric shaft. When the movable jaw rises, the angle between the fixed jaw and movable jaw gets larger, and the materials can be crushed in crusher to reach the crushing target. When the movable jaw is down, the angle between the fixed jaw and movable jaw becomes smaller. The crushed materials are discharged from the lower outlet of the jaw crusher cavity.

Check out the video on how a jaw crusher works

| Model | Max.Feeding size (mm) | Adjustment range of discharge port (mm) | Capacity(t/h) | Power (kw) | Dimensions(L×W×H) (mm) |

| PE 250×400 | 210 | 20-70 | 5-21 | 6P 15 | 1100×1032×1285 |

| PE 400×600 | 340 | 40-100 | 16-64 | 6P 30 | 1623×1736×1615 |

| PE 500×750 | 425 | 50-100 | 40-110 | 6P 55 | 1920×1850×1920 |

| PE 600×750 | 500 | 150-200 | 80-240 | 6P 55 | 2020×1850×1920 |

| PE 600×900 | 500 | 65-160 | 50-160 | 6P 55 | 2530×1900×2340 |

| PE 750×1060 | 630 | 80-180 | 110-320 | 8P 110 | 2680×2380×2785 |

| PE 900×1200 | 750 | 100-200 | 220-380 | 8P 110 | 3470×2876×3330 |

| PE1200×1500 | 1020 | 150-350 | 400-1000 | 8P 160-245 | 4850×3220×3680 |

| PE1500×1800 | 1200 | 220-350 | 500-1200 | 8P 280-380 | 5160×3660×4248 |

| PEX 250×1000 | 210 | 25-60 | 16-52 | 6P 30 | 1580×2006×1390 |

| PEX 250×1200 | 210 | 25-60 | 20-61 | 6P 37 | 1780×2214×1430 |

| PEX 300×1300 | 250 | 20-90 | 16-105 | 6P 55 | 2210×2320×1723 |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

Henan Fote Heavy Machinery Co., Ltd was founded in 1982 in Zhengzhou, Henan, the capital of Chinese machinery manufacturing. The company is large in scale and has four major production bases with a total area of 500,000 square meters, of which standardized heavy industry plants cover an area of 360,000 square meters, providing advanced and reliable infrastructure for production.

Our company focuses on the development and production of mining machinery, including crushers, mills, beneficiation equipment, briquette machines, rotary kilns and other products, which are widely used in mining, chemical industry, construction, coal, ceramics, and other industries. With excellent quality and professional solutions, it has won the trust of customers around the world.

1. We provide customers with a full range of services, including solution design, technical process planning, and the design and manufacturing of standard and non-standard equipment.

2. We dispatch professional technicians to the customer site to assist with shell welding, equipment installation, adjustment, and training of operators.

3. We visit customers regularly to provide lifelong service and technical support.

4. Except for wearing parts, we provide one-year warranty, long-term supply of spare parts, and two-year maintenance of major parts if used correctly.

1. Our equipment holds ISO 9001, CE, and GOST certifications and all equipment undergoes pre-wiring, assembled, and factory tested at our manufacturing facility.

2. We take a test on each machine before delivery.

1. How to get the best price for equipment?

- We are the direct manfacturer, so we can offer you the lowest price than the market price.

- The price of the machine can be given the largest discount based on quantity.

2. Our payment term

- Paypal, T/T, L/C, and Western Union are all available.

- 30% deposit in T/T advance, 70% balance before shipment.

- We take photos of finished products before delivery.

3. Delivery time

- Streamlined production allows for prompt delivery of most products within 6-8 weeks.

- The delivery time will be based on the machine type, selected shipping method, and parts availability.

4. Packaging

- The equipment is wrapped in plastic film before packaging to avoid moisture at sea.

- Bare machines are packed in export containers.

- The motors and small parts are packed in waterproof, sealed, and sturdy wooden cases.

5. Transportation

- Standard container or bulk cargo transportation.

- Sea transportation, air transportation, land transportation, according to customer requirements.

- Complete shipping options and best services at lowest prices are provided: MSC, APL, COSCO, OOCL, CSCL, MSC, MSK, KLINE, etc.

- Seaports in normal use: Qingdao, Tianjin, Shanghai.

- We promise that your goods will be delivered to the destination promptly and safely, and will remind you before the ship arrives.

If you need quality machinery with the latest technology, best prices and fastest delivery, our company is your answer. You are welcome to visit our company and workshop, we sincerely look forward to cooperating with you.