- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

RICHI

-

Voltage:

-

380V/415V/440V/440V

-

Dimension(L*W*H):

-

Customized

-

Motor Power (Kw):

-

22KW

-

Power (kW):

-

280KW

-

Weight (KG):

-

36000 KG

-

Marketing Type:

-

New Product 2021

-

Name:

-

10-20 T/H Pallets Wood Pellet Line

-

Application:

-

Wood Processing Plant

-

Usage:

-

Industrial Profiles

-

Capacity:

-

10-20 Ton Per Hour

-

Type:

-

Vertical Ring Die

-

Motor:

-

Siemens Beide

-

Power Supply:

-

Biomass Pellet Processing Line

-

Mould type:

-

Ring Mould

-

Country:

-

Europe

-

Main Equipments:

-

Chipper Hammer Mill Pellet Mill

Quick Details

-

Pellet Diameter (mm):

-

6 - 12

-

Output (kg/h):

-

10000 - 20000 kg/h

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

RICHI

-

Voltage:

-

380V/415V/440V/440V

-

Dimension(L*W*H):

-

Customized

-

Motor Power (Kw):

-

22KW

-

Power (kW):

-

280KW

-

Weight (KG):

-

36000 KG

-

Marketing Type:

-

New Product 2021

-

Name:

-

10-20 T/H Pallets Wood Pellet Line

-

Application:

-

Wood Processing Plant

-

Usage:

-

Industrial Profiles

-

Capacity:

-

10-20 Ton Per Hour

-

Type:

-

Vertical Ring Die

-

Motor:

-

Siemens Beide

-

Power Supply:

-

Biomass Pellet Processing Line

-

Mould type:

-

Ring Mould

-

Country:

-

Europe

-

Main Equipments:

-

Chipper Hammer Mill Pellet Mill

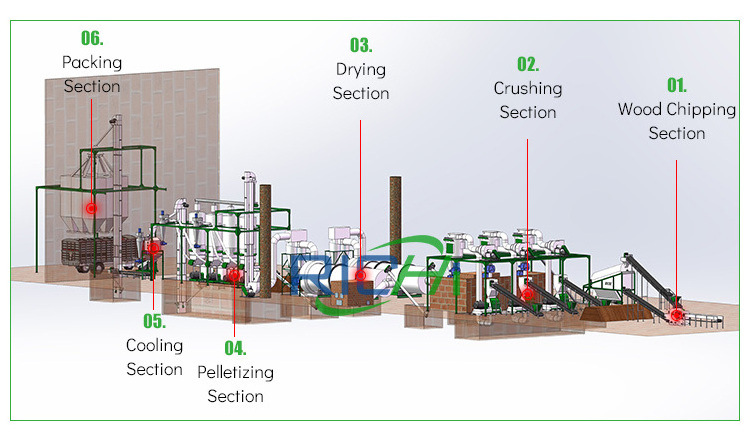

Large-Scale Industrial Use Wood Pallets Pelletizer Pelet Machine For Wood Pellet Line 10-20 Ton Per Hour

- Production Line Name: Large-Scale Industrial Use Wood Pallets Pelletizer Pelet Machine For Wood Pellet Line 10-20 Ton Per Hour

- Capacity Of This Line: 10-20 Ton Per Hour

- Function Description: Making Wood Pellets, Biomass Pellets.

- Type Of Raw Material: Wood Logs, Sawdust, Planks, Straws, Other Biomass Wastes Etc.

- Final Pellet Size: 6/8/10/12mm Or Other Customized Sizes.

- Main Machines Used : Wood Pellet Mill, Drum Type Wood Chipper, Hammer Mill, Rotary Drum Type Drying Machine, Counterflow Cooler, Automatic Packing System.

RICHI's Advantages:

- Ring Die Type Pellet Mill: The high-efficiency ring die type pellet machine can produce high-quality pellets with high compression ratio and high calorific value.

- Long Service Life: Each machine is tested before shipment to ensure that it runs without fault. The main machine adopts Siemens motors and SKF bearings to ensure that the machine can run stably over time.

- Unique Design: Adopting RICHI's exclusive design to make the entire production line efficient and energy-saving. Contact us for more details about our design.

- Customizable: Customized design solutions can handle materials of various sizes and types of raw materials. Meet the different needs of customers in different markets.

- After-sales Service: More than 26 years of production experience, providing installation, training, and continuous after-sales service.

Technical Parameters of The Large-Scale Industrial Use Wood Pallets Pelletizer Pelet Machine For Wood Pellet Line 10-20 Ton Per Hour

| Name | Model | Single Power(KW) |

| Wood drum chipper | RIGX218 | 75 |

| Wood sawdust making hammer mill machine | SFSP66*100 | 132 |

| Pulse dust collector | TBLMa.36b | 11 |

| Widely used wood sawdust rotary dryer | 2400*10000*3 | 37 |

| Latest wood pellet production machine | MZLH Pellet Mill | 250/280 |

| Pellet cooling machine | SKLN24*24 | 1.5 |

| Screener machine | SFJH150*2c/3c | 5.5 |

| Automatic packing machine | DCS Serise Packing System | 3/5 |

| Sewing machine | / | 1.1 |

| MCC Control Center ;Mimic control panel | / | / |

Note: The equipment parameters and the specific details of the production line will depend on different raw materials, capacity and designs.

|

Full Automatic Wood Pellet Line Project Location: America

Power of complete line:

647KW

|

|

|

This project is a competitive price 10 tons per hour full automatic customized wood pellet production line. The customer's main production raw materials are some waste wood, which is relatively large and contains iron nails and other impurities. Therefore, if you want to make wood pellets, you must first slice and crush. We have specially customized the cleaning section for customers, which can screen out iron nails, and then directly slice and crush the waste wood, and then use a high-efficiency wood sawdust hammer mill crusher to crush again to meet the granulation requirements.

The core equipment of this set of equipment is 3 sets of MZLH series ring die wood pelletizer machine, with a single output of about 2.5-4 tons per hour and a power of 250kw. It is our high performance pelletizing equipment, and it is also a wood pelleting equipment that is affirmed by our customers worldwide. |

|

|

Wood Sawdust Pellet Line Project Location: Canada

Power of complete line:

953KW

|

|

|

The raw material for the 20 tons of wood pellet processing project customized for the customer is waste wood, wood log, wood chips, and the pellet size requirement is 6-12 mm. This sawdust production line is large in scale, innovative in design, highly automated,and adopt the turnkey service promoted by RICHI in recent years.

Customer's wood pellets process flow: sawdust raw materials are crushed, broken, dried, granulated, cooled, bagged.Afterwards, it is made into various types and grades of wood pellet fuel for use in power plants and heating. Biomass pellet fuel technology is easier to achieve large-scale production and use. The convenience of using bio-energy pellets is comparable to energy sources such as gas and fuel oil. |

|