- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

XINGYE

-

Power:

-

115kw

-

Dimension(L*W*H):

-

47*21*12.484m

-

Weight:

-

9000 kg

-

Product name:

-

Concrete batching plant

-

Keyword:

-

concrete plant

-

Productivity:

-

90m3/h

-

Application:

-

Roads, Railways, Bridges Construction

-

Mixer type:

-

Twin shafts mixer

-

Control system:

-

Full-automatic

-

Type:

-

Stationary Automatic Concrete Plant

-

Discharging Height:

-

4.1m

-

Advantage:

-

High Production Efficiency

-

Storage Materials:

-

Bulk Cement

Quick Details

-

Machine Type:

-

Batching machine

-

Marketing Type:

-

Hot Product 2024

-

Place of Origin:

-

Jiangxi, China

-

Brand Name:

-

XINGYE

-

Power:

-

115kw

-

Dimension(L*W*H):

-

47*21*12.484m

-

Weight:

-

9000 kg

-

Product name:

-

Concrete batching plant

-

Keyword:

-

concrete plant

-

Productivity:

-

90m3/h

-

Application:

-

Roads, Railways, Bridges Construction

-

Mixer type:

-

Twin shafts mixer

-

Control system:

-

Full-automatic

-

Type:

-

Stationary Automatic Concrete Plant

-

Discharging Height:

-

4.1m

-

Advantage:

-

High Production Efficiency

-

Storage Materials:

-

Bulk Cement

YOU MAY LIKE

Product Description

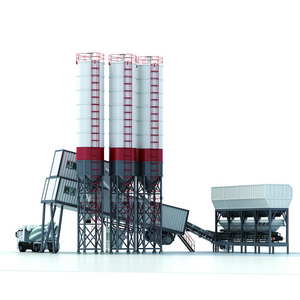

Concrete Batching Plant:

batching machine,concrete mixer,mixing host,cement silo,control room,fully automatic control system.

Mixing system

Equipped with high -wear -resistant alloy stirring arms, high abrasion resistance and strong impact resistance.

Ingredient system

Microcomputer remote control operation

, fast accurate ingredients, simple operation, and strong control function.

Reservoir system

The cement warehouse tank is equipped with a capacity system, which prevent powder from arched.

Conveyor system

Run smoothly, automated, centralized control; long -distance transportation, large transport volume, continuous transportation and other advantages.

Measuring system

Water, cement powder, and external agents are measured by electronic scale; precise ingredients, stable structure.

Control System

Remote management, intelligent control, manual control, and equipment have functions such as alarm correction and operation monitoring.

Specification

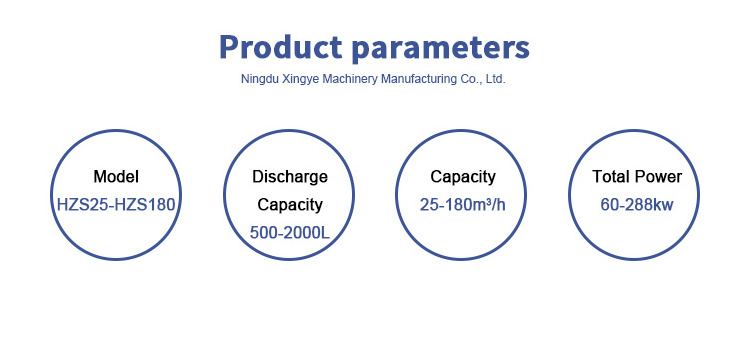

|

Model

|

HZS25

|

HZS35

|

HZS50

|

HZS60

|

HZS75

|

HZS90

|

HZS120

|

HZS150

|

HZS180

|

|

Discharging Capacity (L)

|

500

|

750

|

1000

|

1000

|

1500

|

1500

|

2000

|

2500

|

3000

|

|

Charging Capacity(L)

|

800

|

1200

|

1600

|

1600

|

2400

|

2400

|

3200

|

4000

|

4800

|

|

Maximum Productivity(m³/h)

|

25

|

35

|

50

|

60

|

75

|

90

|

120

|

150

|

180

|

|

Charging Model

|

Skip Hopper

|

Skip Hopper

|

Skip Hopper

|

belt conveyor

|

Skip Hopper

|

belt conveyor

|

belt conveyor

|

belt conveyor

|

belt conveyor

|

|

Standard Discharging Height(m)

|

1.5~3.8

|

2~4.2

|

4.2

|

4.2

|

4.2

|

4.2

|

3.8~4.5

|

4.5

|

4.5

|

|

Number of Species of Aggregate

|

2~3

|

2~3

|

3~4

|

3~4

|

3~4

|

4

|

4

|

4

|

4

|

|

Maximum Aggregate Size(mm)

|

≤60mm

|

≤80mm

|

≤80mm

|

≤80mm

|

≤80mm

|

≤80mm

|

≤120mm

|

≤150mm

|

≤180mm

|

|

Cement/Powder Silo Capacity(set)

|

1×100T

|

2×100T

|

3×100T

|

3×100T

|

3×100T

|

3×100T

|

4×100T or 200T

|

4×200T

|

4×200T

|

|

Mixing Cycle Time(s)

|

72

|

60

|

60

|

60

|

60

|

60

|

60

|

30

|

30

|

|

Total Installed Capacity(kw)

|

60

|

65

|

85

|

100

|

145

|

165

|

210

|

230

|

260

|

Packing and Delivery

Hot Searches