- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Chongqing, China

-

Brand Name:

-

PPGT

-

Voltage:

-

220~415V

-

Power:

-

As Required

-

Dimension(L*W*H):

-

As Required

-

Weight:

-

100000 kg

-

Application:

-

Euro 4 diesel

-

Function:

-

refining

-

Raw material:

-

diesel

-

End product:

-

85-90% diesel

-

Capacity:

-

5-100TPD

-

Advantages:

-

To produce premium diesel

-

Structure:

-

TFE/WFE/Fractional vacuum distillation

-

Technology:

-

solvent extraction

-

Environmental protection:

-

Exhaust emission system

-

Working temperature:

-

80~180℃

Quick Details

-

Applicable Industries:

-

Waste Oil To Diesel Equipment

-

Marketing Type:

-

New Product 2021

-

Flow:

-

5~200TPD

-

Place of Origin:

-

Chongqing, China

-

Brand Name:

-

PPGT

-

Voltage:

-

220~415V

-

Power:

-

As Required

-

Dimension(L*W*H):

-

As Required

-

Weight:

-

100000 kg

-

Application:

-

Euro 4 diesel

-

Function:

-

refining

-

Raw material:

-

diesel

-

End product:

-

85-90% diesel

-

Capacity:

-

5-100TPD

-

Advantages:

-

To produce premium diesel

-

Structure:

-

TFE/WFE/Fractional vacuum distillation

-

Technology:

-

solvent extraction

-

Environmental protection:

-

Exhaust emission system

-

Working temperature:

-

80~180℃

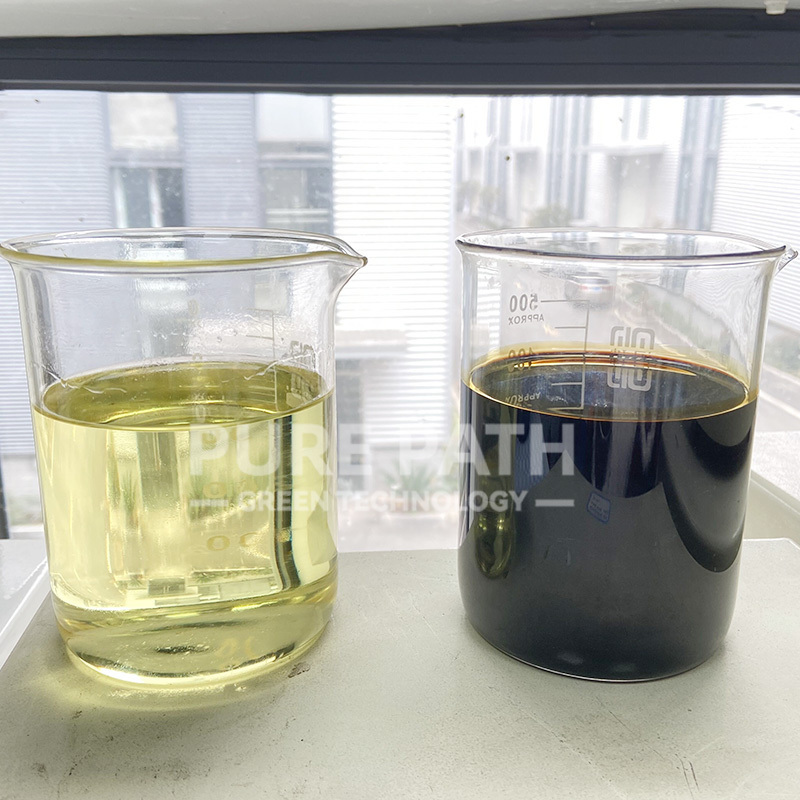

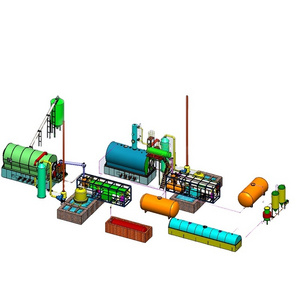

We are proud to present you with our

VP-BP waste oil recycling plant

which is combined with dozens of our newest technologies to delivery you with the excellent quality of base oils out of different type of car engine and machinery engine or industrial waste oil.

As the manufacturer, Vpure owns professional engineering team to provide constructively project proposal according to different waste oil feedstock or standard requirement of the final oil products.

In order to get a golden clear distillates, genuine continuous fractional distillation, wiped film distillation and molecular distillation are optional. Before the process of distillation begins, we also highlight the equally important steps prior to vacuum distillation.

A concurrent pretreatment solid removal and dehydration and defueling process could also upgrade the quality of oil products and increase the working efficiency.

SPECIFICATIONS OF VP-BP OIL RECYCLING MACHINE

| Model No. | VP-BP-1 | VP-BP-2 | VP-BP-3 | VP-BP-4 | VP-BP-5 | VP-BP-6 | VP-BP-7 | VP-BP-7 |

| Items. | ||||||||

| Process Capacity Max. | 2 TPD | 5 TPD | 10 TPD | 15 TPD | 20 TPD | 30 TPD | 50 TPD | 100 TPD |

| Heating Power | 17KGS LPG/20KGS FUEL OIL/230KWH/PER TON OF WASTE OIL | |||||||

| Power Consunmption | 25KWH PER TONS OF WASTE OIL | |||||||

| Vacuum Degree | Less then -0.05KPa | |||||||

| Heating Method | Fuel Oil/Natural Gas/LPG/Electricity | |||||||

| Heating Temp. | 30-350℃ | |||||||

| Voitage | 220/380/415v 50/60HZ | |||||||

| Noise | ≤60dB | |||||||

| PROPERTY | METHOD | RESULT UNITS | |

| Type | LBO | HBO | |

| Appearance | Visual Inspection | Bright&Clear | Bright&Clear |

| Color scale | ASTM D1500 | ≤1 | ≤1.5 |

| Water Content | ASTM D1744 | Trace (% wt) | Trace (% wt) |

| Kinematic Viscosity at 40℃ | ASTM D445-15a | 32.170 mm2/s | 67.420 mm2/s |

| Viscosity Index | ASTM D2270-10 | 117 | 122 |

| Total Sulfur Content | ASTM D4294-16e1 | 0.0071 %(m/m) | 0.0093 %(m/m) |

| Density at 15 ℃ | ASTM D4052-18 | 0.898 kg/m3 | 0.917 kg/m3 |

| Pour Point | ASTM D97-17b | -18 ℃ | -21 ℃ |

|

Copper Strip Corrosion

(3h/100℃) |

ASTM D130-18 | 1a Rating | 1a Rating |

| Total Acid Number | ASTM D974 | 0.01(mg KOH/g) | 0.01(mg KOH/g) |

| Carbon Residue Conradson | ASTM D189 | 0.01(% wt) | 0.01(% wt) |

| Smell | Organoleptic | No Smell | No Smell |