- Product Details

- {{item.text}}

Quick Details

-

Bottle Volume(ml):

-

500 ml

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

XINMAO Machinery

-

Year:

-

2023

-

Voltage:

-

380V, by order

-

Dimension(L*W*H):

-

By order

-

Hollow part volume:

-

adjustable

-

Clamping Force (kN):

-

360

-

Power (kW):

-

according to model

-

Weight (KG):

-

1600 KG

-

Bottle size:

-

200ml to 2000ml

-

Delivery time:

-

45days

-

Touch screen:

-

Siemens

-

PLC:

-

Siemens

-

Air-break switch:

-

Mitsubishi

-

Production Capacity (BPH):

-

4000

-

Certification:

-

CE , ISO9001:2000

Quick Details

-

Neck Diameter(mm):

-

28 mm

-

Max.Bottle Diameter(mm):

-

180 mm

-

Max.Bottle Height(mm):

-

360 mm

-

Bottle Volume(ml):

-

500 ml

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

XINMAO Machinery

-

Year:

-

2023

-

Voltage:

-

380V, by order

-

Dimension(L*W*H):

-

By order

-

Hollow part volume:

-

adjustable

-

Clamping Force (kN):

-

360

-

Power (kW):

-

according to model

-

Weight (KG):

-

1600 KG

-

Bottle size:

-

200ml to 2000ml

-

Delivery time:

-

45days

-

Touch screen:

-

Siemens

-

PLC:

-

Siemens

-

Air-break switch:

-

Mitsubishi

-

Production Capacity (BPH):

-

4000

-

Certification:

-

CE , ISO9001:2000

Xinmao Drink Machinery.

Our company specializes in manufacturing various kinds of drinking machines. Recently, our company has imported the 90' advanced equipment from Germany. We have professional technicians for the research, design, development and manufacture. With advanced technology, superior quality products and perfect and efficient after-sales service, we offer consulting service of factory construction, installment and testing, technical training and technical reform of equipment.We regard "product quality" as the life of enterprise development. We have set up a strict quality inspection system. Our quality aim is "quality first, consumer supreme". We welcome customers both at home and abroad to cooperate with us.

Products Description

Full Automatic PET Bottle Blowing Machine.

Full automatic blow molding machine is suitable for producing PET plastic containers and bottles in all shapes. It is widely used to produce the carbonated bottle, mineral water, pesticide bottle oil bottle cosmetics, wide-mouth bottle and hot fill bottle etc.

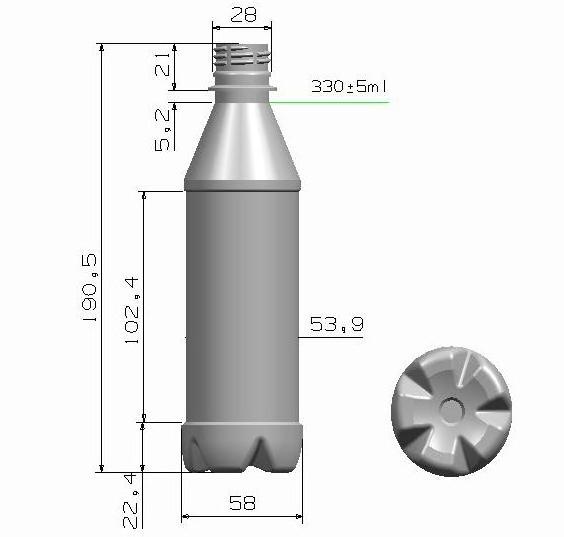

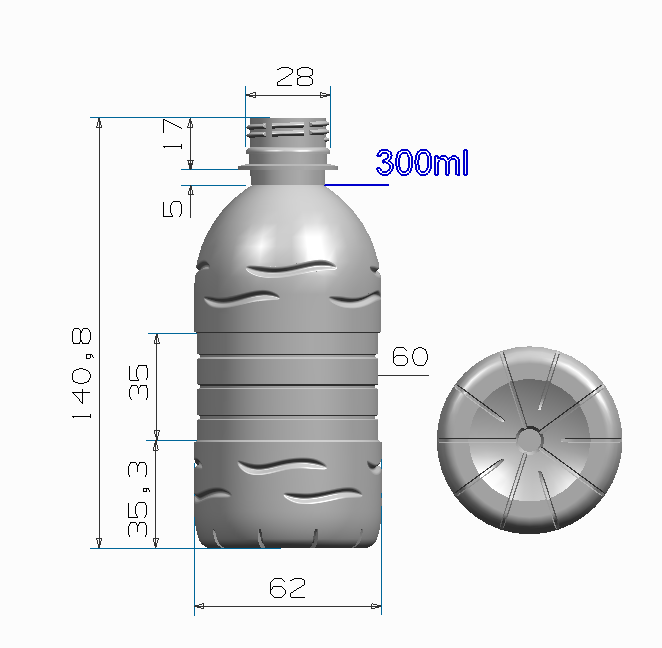

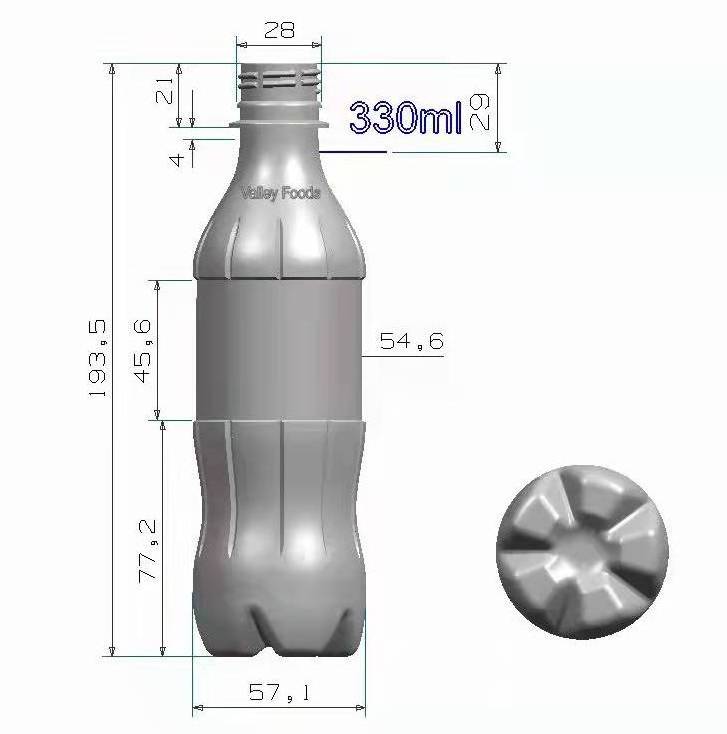

Final Products

|

Container |

Max Container Volume( Itr)

|

2

|

|

|

Max Neck Diameter( mm)

|

50

|

|

|

Max Container diameter( mm)

|

110

|

|

|

Max Container Height( mm)

|

320

|

Details Images

New Auto Preform Unscrambler System.

*Adopts one-way preform-feeding structure and preform-separating by servo motor structure which solve the preform block and abrasion problem.

*There are two photoelectric sensors to control preform-loading motor and preform-separating cylinder that will warn the operator to add the preforms into the hopper when lacks preform instead of stopping the machine.

*There are two photoelectric sensors to control preform-loading motor and preform-separating cylinder that will warn the operator to add the preforms into the hopper when lacks preform instead of stopping the machine.

New Heating System.

*Perfect heating system design decrease power consumption.

*Special oven design helps power saving and easy maintain.

*Each lamp position and temperature can be adjusted.

*Cycle air-cooling system keeps the oven temperature constantly.

*Special oven design helps power saving and easy maintain.

*Each lamp position and temperature can be adjusted.

*Cycle air-cooling system keeps the oven temperature constantly.

Easy To Change Bottle Shape.

*Drawer type mold structure design is easy for mold changing. Within one hour can change a mold on the condition of same bottle neck diameter.

Molder

1. PET mould is designed by 3D computer drawing to improve the success rate of bottle blowing.

2. PET mold is made of alloy steel and stainless steel, durable and stable.

3. Short, improve production efficiency.

4. Design and manufacture of various moulds, and design bottle embryo according to the bottle body.

5. High precision machine parts and high precision machining process.

6. The quality control process is strictly controlled and the product quality is guaranteed.

7. Cooperate with customers in R & D, design and manufacturing.

Product Paramenters

|

Model |

XM-2000

|

XM-4000

|

XM-6000

|

|

Cavity

|

2

|

4

|

6

|

|

Capacity

|

1600-2000pcs/h

|

3000-3500pcs/h

|

5500-6000pcs/h

|

|

Diameter of bottle’s body

|

80-95mm

|

80-110mm

|

130-360mm

|

|

Height of bottle

|

50-320mm

|

50-380mm

|

20-950mm

|

|

Diameter of bottle’s mouth

|

15-38mm

|

15-38mm

|

18-38mm

|

|

Installed power/Actual power

|

20kw/15kw

|

48kw/30-35kw

|

48kw/35-40kw

|

|

Air source

|

2.0m3/min 3.5MPa

|

3.0m3/min 3.0MPa

|

8.0m3/min 3.0MPa

|

|

Size

|

2500*1850*1700mm

|

2700*2100*2030mm

|

4000*2000*2020mm

|

Recommend Products

Hot Searches