- Product Details

- {{item.text}}

Quick Details

-

Throat Depth (mm):

-

320 mm

-

Width of Working Table (mm):

-

1250 mm

-

Place of Origin:

-

Jiangsu, China

-

Weight (KG):

-

14300

-

Motor Power (kw):

-

11 kw

-

Product name:

-

Panel Center Bender

-

Keyword:

-

Panel Center Bender

-

Type:

-

Hydraulic Bending Tools

-

Application:

-

Stainless Plate Bending

-

Raw Material:

-

Sheet

-

Control system:

-

Star300-LGx

-

CNC or not:

-

CNC BendingMachine

-

Color:

-

Customer Choose

-

Material:

-

Metal Steel Sheet

-

Certification:

-

CE ISO SONCAP

Quick Details

-

Machine Type:

-

Synchronized

-

Length of Working Table (mm):

-

2500

-

Slider Stroke (mm):

-

120 mm

-

Throat Depth (mm):

-

320 mm

-

Width of Working Table (mm):

-

1250 mm

-

Place of Origin:

-

Jiangsu, China

-

Weight (KG):

-

14300

-

Motor Power (kw):

-

11 kw

-

Product name:

-

Panel Center Bender

-

Keyword:

-

Panel Center Bender

-

Type:

-

Hydraulic Bending Tools

-

Application:

-

Stainless Plate Bending

-

Raw Material:

-

Sheet

-

Control system:

-

Star300-LGx

-

CNC or not:

-

CNC BendingMachine

-

Color:

-

Customer Choose

-

Material:

-

Metal Steel Sheet

-

Certification:

-

CE ISO SONCAP

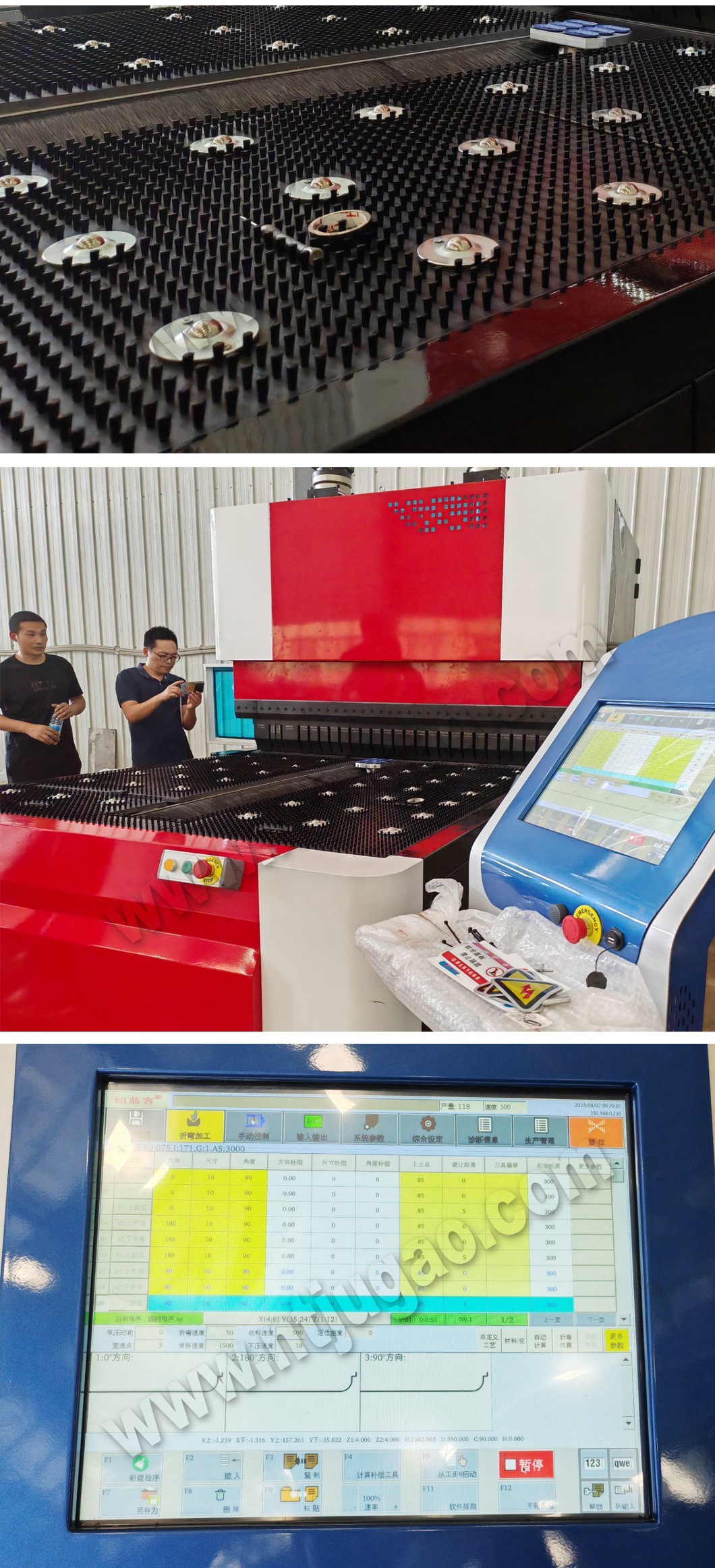

Full Automatic Panel Bender Flexible Sheet Metal Bending Center Bending Machine for Sheet Metal

Performance characteristics

FLC Series panel bender is the new generation automated bending solutions, a benchmark that indicates the upgrading to automation of sheet metal fabricating industry. It can obviously reduce the labor cost and at the same time it can realize 300% higher efficiency comparing to traditional press brake up to 0.3s per bending. Full electro servo transmission plus closed-loop BUS control makes the accuracy far better.

1. The main function is to realize the automatic bending of edges. A platecan be folded into four sides or even more;

2. The NC positioning device is used for automatic positioning, and themultilateral bending is completed at one time, which shortens thebending timeThe bending cycle time controls the shearing error of theplate to the first bending edge;

3. The mechanical stop block further ensures the accuracy of eachpositioning dimension. Due to the bending multilateralFunction of:

Technical parameter

| Model | Bendinglength | Platelength | Plate width | Bendingheight | Mainmum moldingsize of four sides | Mainmum fomingsize of four sides | Mainmumatc radius | The fastest continusbending speed |

| FLC-1000 | 1200 | 1100 | 600 | 175/320 | 320x200 | 320x200 | 1.2 | 0.5s |

| FLC-1600 | 1500 | 1700 | 800 | 175/320 | 320x200 | 320x200 | 1.2 | 0.5s |

| FLC-2000 | 2000 | 2100 | 1250 | 175/320 | 320x200 | 320x200 | 1.2 | 0.5s |

| FLC-2500 | 2500 | 2600 | 1250 | 175/320 | 320x200 | 320x200 | 1.2 | 0.5s |

| Model | TDistance between upper | Bending angle | Mainmumatc radius | Max.thickness of material | CNCsystem | Numberof axes | Dimension LxWxH |

| FLC-1000 | 180 | 0-180 | 1.2 | Aluinum plate :2.0 arbon steel plate: 1.5 Stainless steel :1.2 | Star300-LGx | 7 axes standard, 8/9 optional | 2900x1390x2600 |

| FLC-1600 | 180 | 0-180 | 1.2 | 10 axes standard, 11/12 optional | 3370x1890x2650 | ||

| FLC-2000 | 180 | 0-180° | 1.2 | 11 axes standard, 13/15 optional | 4480x2390x2700 | ||

| FLC-2500 | 180 | 0-180° | 1.2 | 11 axes standard, 13/15 optional | 5280x2900x2700 |

Guarantee period:

Our product quality guarantee period is 12 months from B/L date. During guarantee period, we will provide spare parts without any charge in case of quality discrepancy caused by us. If the malfunctions are caused by customers’ incorrect operations, we will provide customers spare parts at cost price. We also can offer flexible extended warranties according to the actual situation.

After-sales services:

Our engineer can go to your factory for installation and showing operation details on condition of you provide the round-trip air tickets, visa formalities, food and accommodation. In turn, your engineers can come to our factory for learning the installation, operation and maintenance for free.

Why Choose Us:

1. We will run the machine for a few days, and use your materials to do the test. Only guarantee the machine shows best performance, and then we will ship out.

2. Our elite teams can provide you professional, customized, and all-round services around the clock. If you need any help, contact us by WHATSAPP, Skype, Email or Telephone.

How can we provide you efficient services (metal processing solution):

There are Three Steps as following:

1. Gather your requirements based on your real working situation.

2. Analyze your information and provide our feedback.

3. Offer options based on your specific needs. For instance, reg. standard products, we can offer professional recommendations; reg. non-standard products, we can offer professional designing.