Shaking table is a flagship mining equipment with more than 30 years experiences in JXSC factory.

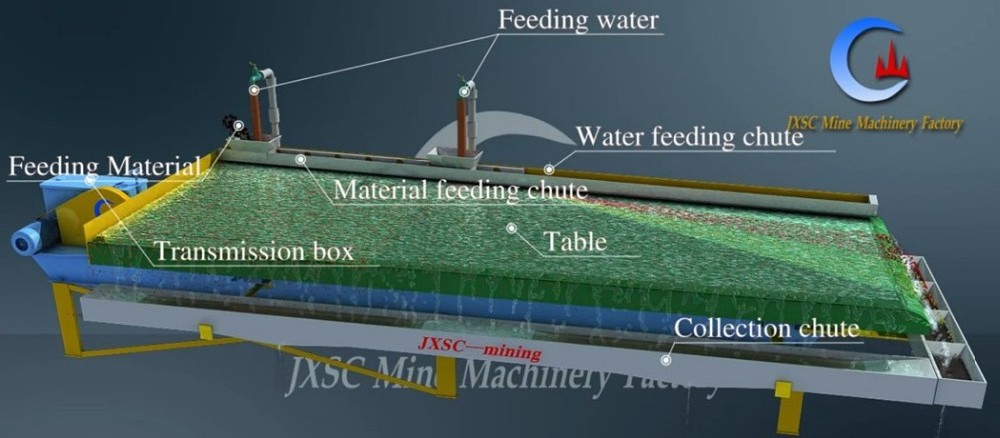

It is a gravity wet process mine machinery, the table deck is made of fiber glass reinforced with wearable corundum surface. Mining shaker table is composed of three parts: head motion of shaking table, table deck of shaking table, as well as bearing and adjusting gradient.

Shaking table widely used to separate gold, tin, tungsten, chromite, silver, diamond, zircon, cobalt, tantalum-niobium, lead, zinc, copper, antimony, other rare metal and noble metal ores.

- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V or as requested

-

Dimension(L*W*H):

-

As per specific model

-

Weight:

-

350 KG

-

Recovery Rate:

-

90-95%

-

Material of Deck:

-

Fiber Glass

-

Beneficiation Area:

-

7.6m2, 4.08m2, 1.95m2, 05m2 available

-

Feed Size:

-

0.1-3mm

-

Feeding Density:

-

10-30%

-

Capacity:

-

0.05-2TPH

-

Application mine:

-

Gold, Tin, Chrome, Tantalum-niobium, Manganese mine etc

-

Water Added:

-

0.1-1.5TPH

-

Motor Power:

-

1.1Kw

-

Keywords:

-

shaker table,shaking table,6s shaker table,gold shaker table

Quick Details

-

Production Capacity:

-

0.05-2 tph

-

Place of Origin:

-

Jiangxi, China

-

Brand Name:

-

JXSC or customerized

-

Voltage:

-

380V or as requested

-

Dimension(L*W*H):

-

As per specific model

-

Weight:

-

350 KG

-

Recovery Rate:

-

90-95%

-

Material of Deck:

-

Fiber Glass

-

Beneficiation Area:

-

7.6m2, 4.08m2, 1.95m2, 05m2 available

-

Feed Size:

-

0.1-3mm

-

Feeding Density:

-

10-30%

-

Capacity:

-

0.05-2TPH

-

Application mine:

-

Gold, Tin, Chrome, Tantalum-niobium, Manganese mine etc

-

Water Added:

-

0.1-1.5TPH

-

Motor Power:

-

1.1Kw

-

Keywords:

-

shaker table,shaking table,6s shaker table,gold shaker table

Overview of 6s Shaking Table

Working Principle of 6s Shaking Table:

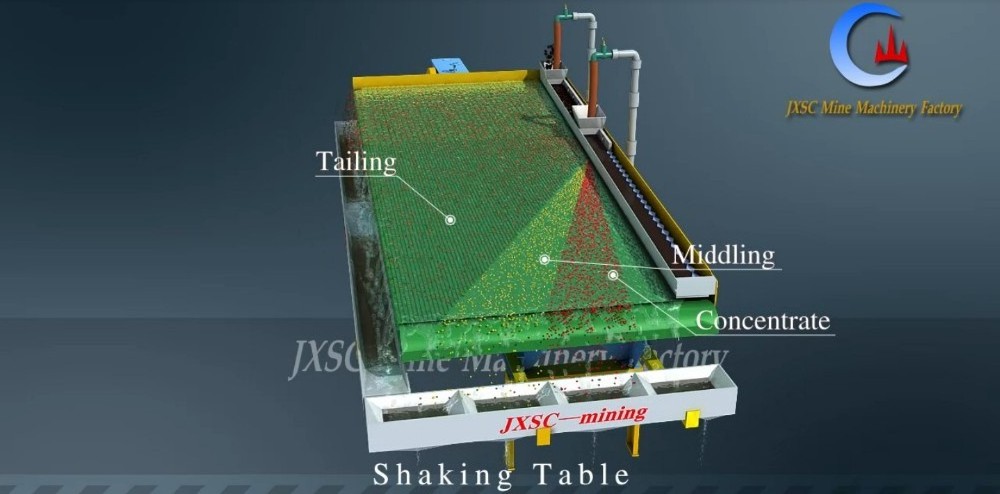

The working principle of Shaker Table is separating the heavy material from light material by using their different proportion & specific gravity, under the effect of gravity, the minerals will divide into the ore concentrate, the middling and the tailing.

The prominent advantage of ore shaking table is precise separation.

The enrichment ratio of concentrate is very good, up to 95% high recovery ratio for kinds of heavy minerals, when dealing with low grade tungsten ore and tin ore, the enrichment ratio could reach about 300 times.

we can get some final concentrates, final tailings and 1 or 2 kinds of middling products after first separating from the feeding mineral.

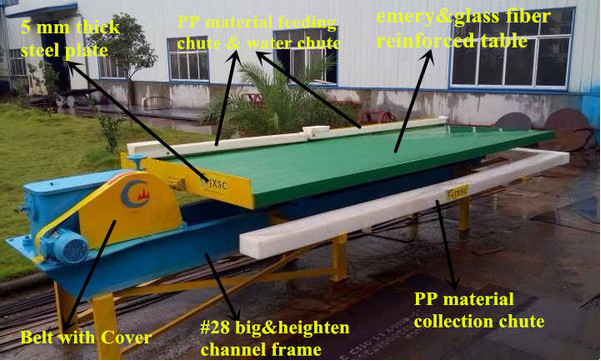

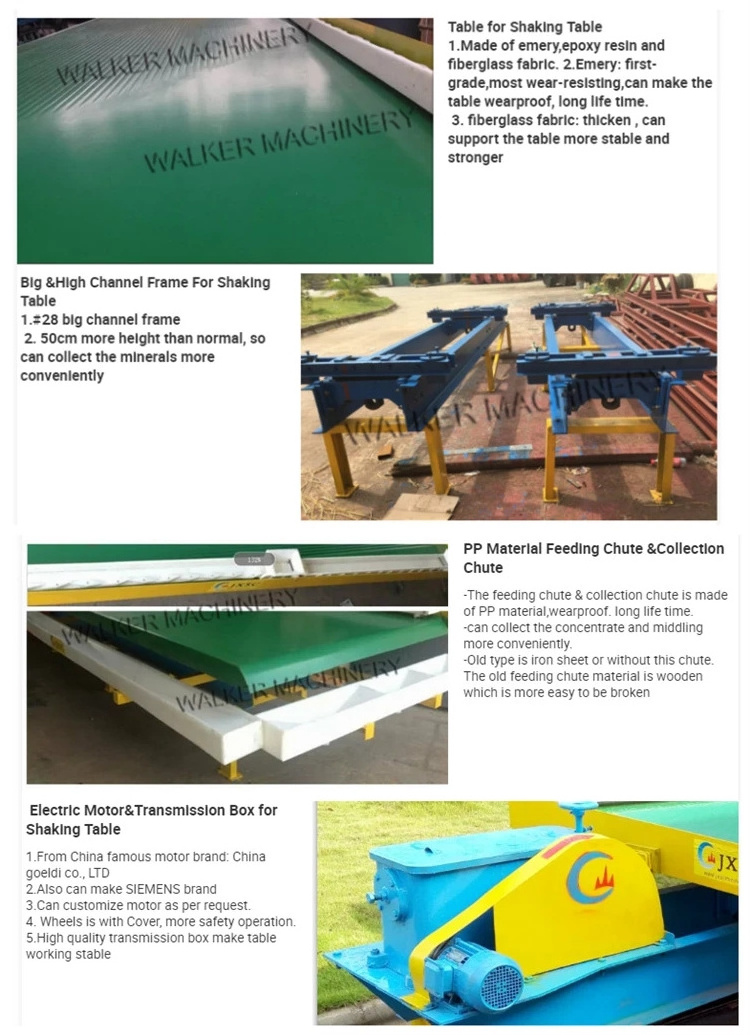

2.Heighten the channel frame.

3.Add a protective cover on the belt.

4.Thicken the steel plate to 5 mm.

5.Reinforce the table with emery and glass fiber material.

(Strongly recommend 6s shaking table)

Technical Parameters of 6s Shaking Table

98% Recovery Rate 6s Shaking Table Gold Shaking Table for Gold Mine Dressing in Ghana, West Africa Gold Processing Plant

|

Model

|

|

6-s 7.6

|

6-s 7.6

|

6-s 7.6

|

6-s 4.08

|

6-s 1.95

|

6-s 0.5

|

|||

|

Deck type

|

|

Course sand

|

Fine sand

|

Slime Deck

|

Three different kinds of decks are available

|

|

|

|||

|

Beneficiation Area m2

|

|

7.6

|

7.6

|

7.6

|

4.08

|

1.95

|

0.5

|

|||

|

Deck Size

|

Length mm

|

4450

|

4450

|

4450

|

3000

|

2100

|

1100

|

|||

|

|

transmission end width mm

|

1855

|

1855

|

1855

|

1320

|

1050

|

500

|

|||

|

|

Concentrate end width mm

|

1546

|

1546

|

1546

|

1100

|

850

|

430

|

|||

|

Maximum Feeding Size mm

|

|

2

|

0.5

|

0.15

|

0.1-2

|

0.074-2

|

0.074-2

|

|||

|

Feeding Amount t/d

|

|

30-60

|

10-20

|

15-25

|

0.4-1.5t/h

|

0.3-0.8t/h

|

0.05-0.2t/h

|

|||

|

Feeding Density %

|

|

25-30

|

20-25

|

15-25

|

10-30

|

|

|

|||

|

Stroke mm

|

|

16-22

|

11-16

|

8-16

|

6-30

|

12-28

|

9-17

|

|||

|

Frequency f

|

|

45-48

|

18-53

|

50-57

|

210-320

|

250-450

|

280-460

|

|||

|

Water added t/d

|

|

80-150

|

30-60

|

10-17

|

0.3-1.5t/h

|

0.2-1t/h

|

0.1-0.5t/h

|

|||

|

Transverse slope of

Deck °

|

|

2° 30-4° 30

|

1° 30-3° 30

|

1° -2°

|

0 -10°

|

0 -8°

|

0 -10°

|

|||

|

Longitudinal slope of Deck °

|

|

1.4

|

0.92

|

------

|

------

|

------

|

------

|

|||

|

Cross-section Shape of Deck

|

|

rectangular

|

saw tooth

|

triangle

|

Avaliable rectangular, saw tooth, triangle

|

|

|

|||

|

Motor Power KW

|

|

1.1

|

1.1

|

1.1

|

1.1

|

1.1

|

1.1

|

|||

Jiangxi Shicheng Mine Machinery Factory

Jiangxi Shicheng Mine Machinery Factory is an experienced supplier of complete set mining equipments, professional at providing complete set processing equipments for Gold ore /Tin ore /Tungsten ore /Iron ore / Diamond/ Coltan ore / Silica sand / Zircon sand/ Black sand/Chrome ore, ect. As well as complete set small lab mining machines.

Our Core Advantages as below

1.+30 years history FACTORY at mining machinery

2.Provide engineer team after sales service

3.Provide Complete set mineral processing plant

4.Provide Sample testing service in factory lab for free

5.Provide professional Mining Solution Consulting

Below is our factory workshop:

JXSC Mine Machinery Factory has obtained ISO9001:2008 standard certificate, most mining machines obtained CE, SGS and BV certificate.

Pre-Sales Service

*Inquiry and consulting support

*Ore sample testing support

*View our Factory

*Design Flowchart

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* 1 year warranty

*

Engineers available to service machinery overseas.

Answer: Our products are manufactured strictly according to national and international standard, and we will do a test on every machine before delivery.

2.Guaranteed?

Answer: All of our products are guaranteed for one year. If products quality is not consistent with the description or promise we made before you place order, we promise 100% refund.

3.How about price?

Answer: For the complete same machine, we can promise our quality is the best when the price same as other competitors, and our price can be lowest when the quality at standard level.

4.Service and Payment Terms?

Answer: We can accept T/T and L/C; 30% deposit, 70% balance before factory delivery, which is international trade practice; Finished product pictures will be provided to customers before delivery.

1. Which machine do you need? like gold washing machine, spiral chute, vibrating screen, Jig separator, Shaking table, etc.

2. What is your raw ore that you plan to process? like gold ore, diamond ore, tantalite or silica sand, etc.

3. What is the capacity you need? Like 10 tones per hour.

4. What is the feeding size to the machine? and what is the discharging-material size that you require?

Sincerely welcome to send your inquiry,you can get best quotation and professional service.