- Product Details

- {{item.text}}

Quick Details

-

Printing Type:

-

All

-

Weight (KG):

-

2

-

Place of Origin:

-

shandong

-

Brand Name:

-

JCTPRINT

-

Product name:

-

Manual tension controller with magnetic powder brake or clutch

-

Usage:

-

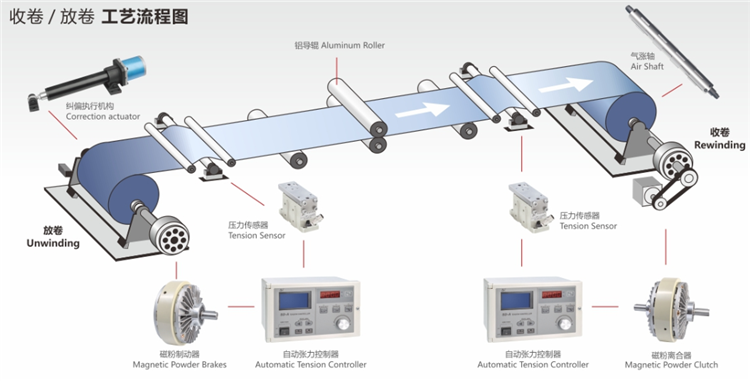

Rewing/unwinding system

-

Load cell:

-

Have

-

Suitable printer:

-

All kinds of printing machines

-

Delivery time:

-

4-7 Working Days

-

Sampling speed:

-

100millisecond

-

Power supply:

-

AC 180V-240V 50/60Hz

-

Measurement accuracy:

-

1Newton

-

Model:

-

SD-A,SD-B,SD-C,ST200P

-

MOQ:

-

1 Set

Quick Details

-

Condition:

-

New

-

Type:

-

tension controller

-

Use:

-

All

-

Printing Type:

-

All

-

Weight (KG):

-

2

-

Place of Origin:

-

shandong

-

Brand Name:

-

JCTPRINT

-

Product name:

-

Manual tension controller with magnetic powder brake or clutch

-

Usage:

-

Rewing/unwinding system

-

Load cell:

-

Have

-

Suitable printer:

-

All kinds of printing machines

-

Delivery time:

-

4-7 Working Days

-

Sampling speed:

-

100millisecond

-

Power supply:

-

AC 180V-240V 50/60Hz

-

Measurement accuracy:

-

1Newton

-

Model:

-

SD-A,SD-B,SD-C,ST200P

-

MOQ:

-

1 Set

Automatic tension controller rewinding system controller for machine

1.Introduction

The tension control of the tension controller refers to the ability to permanently control the tension of the tape as it is transported on the device.

Automatic tension controller is mainly made up of tension detector, high accuracy A/D, D/A converter and microcomputer of high performance…etc. It realizes permanent tension of roll materials according to compare the tension of roll material measured by tension detector with the goal tension of settlement first, then through microcomputer PID operation and adjusting D/A output to change excitation electric current of magnetic powder clutch/ brake or torque of servomotor automatically. The controller can be used in several occasions needed to carry on measuring and controlling accurately with the tension and have application extensively with flexible in usage.

2.Classification

Our company's tension controller can be divided into automatic tension controller and manual tension controller.

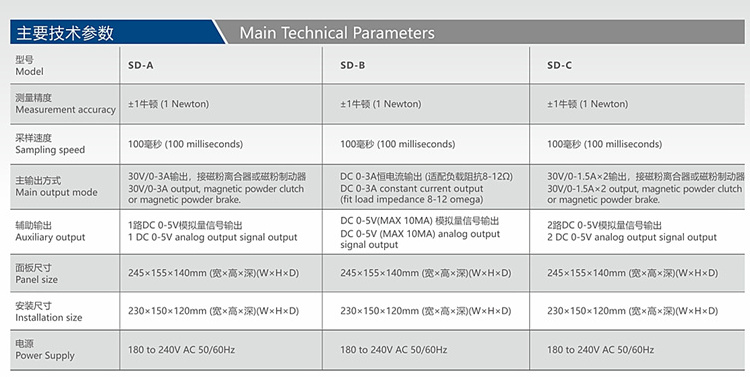

01.Automatic tension controller

|

Model |

SD-A |

SD-B |

SD-C |

|

Measurement accuracy |

1Newton |

1Newton |

1Newton |

|

Sampling speed |

100millisecond |

100millisecond |

100millisecond |

|

Main output model |

30V/0-3A Output,connecting with magnetic powder brake or clutch |

DC 0-3A Constant current output

( adapter load impedance

|

30V/0-1.5A ×2 output,connecting with magnetic powder brake or clutch |

|

Auxiliary output |

1path DC 0-5V Analog signal output |

DC 0-5V Analog signal output(Max 10MA) |

2path DC 0-5V Analog signal output |

|

Panel Size(W*H*D) |

245*155*140mm |

245*155*140mm |

245*155*140mm |

|

Installation Size(W*H*D) |

230*150*120mm |

230*150*120mm |

230*150*120mm |

|

Power supply |

AC 180V-240V 50/60Hz |

AC 180V-240V 50/60Hz |

AC 180V-240V 50/60Hz |

SD-A Automatic Constant Tension Controller through receiving the signals from two tensionsensor, comparing the tension with the set target tension to control the magnetic powder clutch,brake, torque motor or servo motor to achieve automatic controlling the tension of unwindingor rewinding for the long-sized roll materials, particularly suitable for printing machines, sitingmachines, coating machines, and laminating machines.

SD-B Automatic Constant Tension Controller is mainly composed of tension sensor, high- precisionA/D, D/A converter and high-performance single chip microcomputer. This automatic tensioncontroller through comparing the tension measured by the tension sensor with the set targettension, and use single chip microcomputer PID to automatically adjust the D/A output to changethe excitation current of magnetic powder clutch or brakes to achieve constant tension whenrewinding and unwinding, which can be widely used in a variety of situations that require precisemeasurement and control of the tension, can be flexible and wide applicability.

SD-C Automatic Constant Tension Controller is designed for printing machines. It has two outputsto enable pre-starting automatic shaft change for the double-position winding of the printingmachine, and it also has the output function of automatic pick-up and cut.

02 Manual tension controller

A. ST-200P

ST-200P tension controller is suitbale for the magnetic powder brake or clutch under 10kg.

B. ST-200W

ST-200W tension controller is suitbale for the magnetic powder brake or clutch over10kg.

C. SDZK-A

SDZK-A is manual pointer model tension controller.

3.Advantages of our tension controller

A. Advantages of automatic tension controller

01. Automatic unwind tension system deploys material tension detection roller.

2. The device will support auto-stop operation when material tension reaches the upper and lower limitation.

3. Unwinder device deploys automatic compensation tension control device.

4. The rotation speed then pre-set tension maintain by the roller when printing material rotate through the printing machine, no matter what the size, width, material.

5. Tension sensors roller monitor the roller tension of the material and amend any changes of the tension.

B. Advantages of manual tension controller

1. Has overcurrent, overheating, short circuit protection.

2. 24V, 36V, 48V series voltage output technology.

3. Unique multi-turn precision trimming technology adjust the slightest nuanced.

4. 2A-4A has a strong and constant output current, complete specifications, chosen at random.

5. Has diversified control mode (panel, PLC, external potentiometer).