- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Application:

-

Reed Switch

-

Brand:

-

Reed Switch

-

Product name:

-

reed switch

-

Certification:

-

standard

Quick Details

-

Brand Name:

-

Smart

-

Model Number:

-

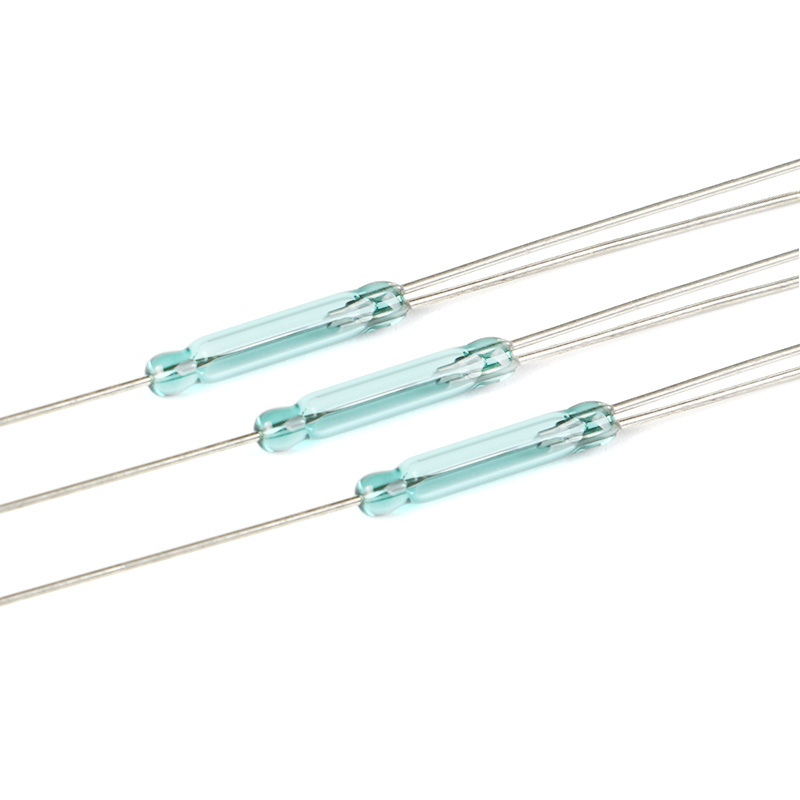

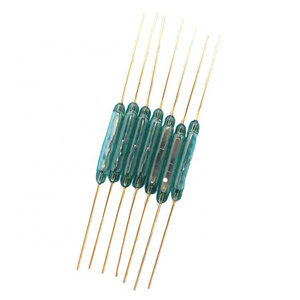

2.5*14mm

-

Type:

-

Reed Switch

-

Place of Origin:

-

Guangdong, China

-

Application:

-

Reed Switch

-

Brand:

-

Reed Switch

-

Product name:

-

reed switch

-

Certification:

-

standard

≡≡≡≡≡ Welcome to Smart ≡≡≡≡≡

We offer one-stop service for PCB/PCBA/FPC/heatsink/membrane switch, all kinds modules, sensors, Connector & Cables and electronics components.

Best price ,Best quality,Best lead time ,Best service!

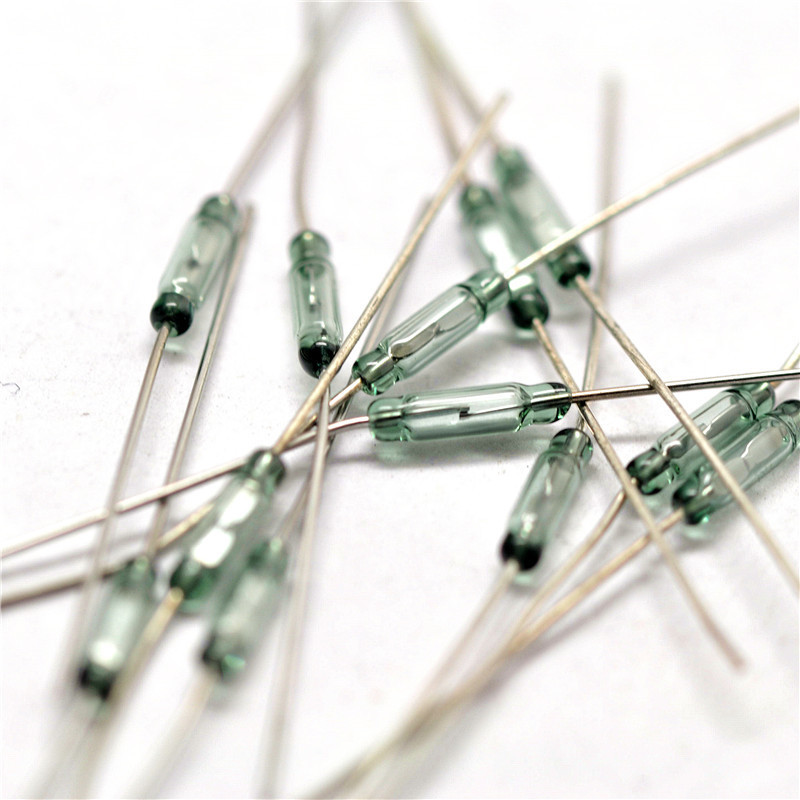

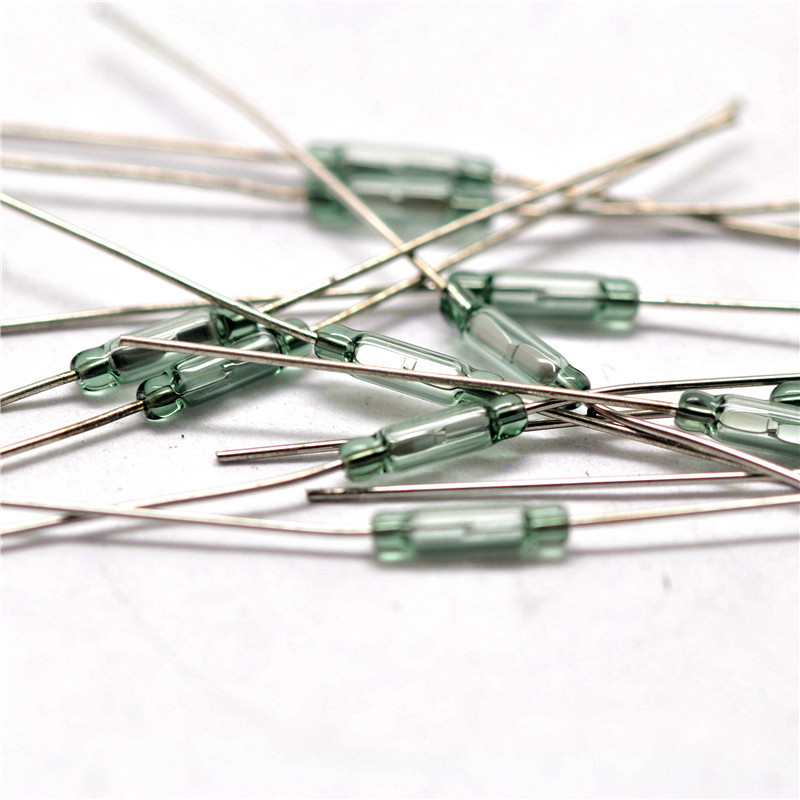

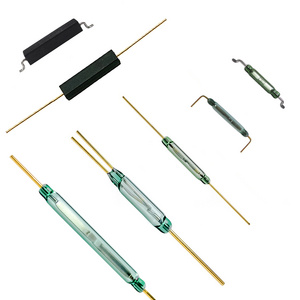

| Reed Switch 3 pin Magnetic Switches 2.5*14mm Normally Open Closed 2.5X14MM NO NC Conversion for Sensors |

- Contact method A

- Maximum power 6W

- Maximum switching voltage 60VDC/VAC

- High pressure resistant 60VDC/VAC

- Maximum switching current 0.25A

- Maximum load current 0.5A

- Maximum contact resistance 115M

- Action time 0.25ms

- Bouncing time 0.05ms

- Response frequency 3000Hz

- Sensitivity value 10~20AT

- Minimum reset sensitivity 5FT

- Maximum contact capacitance 2.0PF

- Electrical life (load) 5x106 (50mV, 10mA)

- Test coil turns / resistance 5000/600 ohms

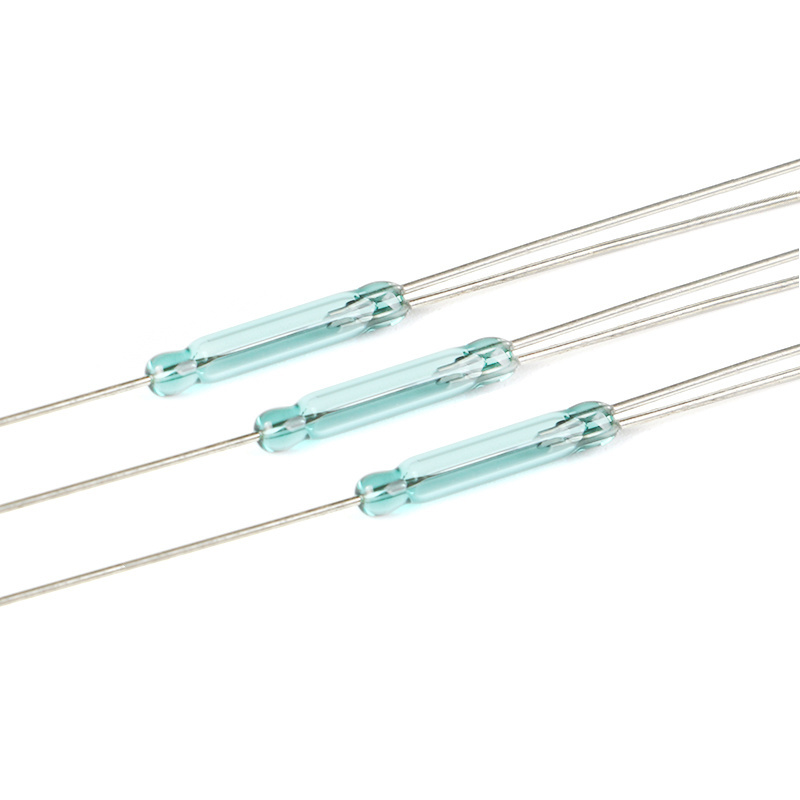

- The dry reed pipe is compact and lightweight, and can be installed in extremely limited space, making it ideal for miniaturized equipment.

- The dry reed switch components are hermetically sealed in an inert gas atmosphere, never in contact with the outside environment, and have a long working life.

- The dry reed pipe does not use sliding elements, so there is no metal fatigue associated with all metal degradation, ensuring virtually unlimited mechanical life.

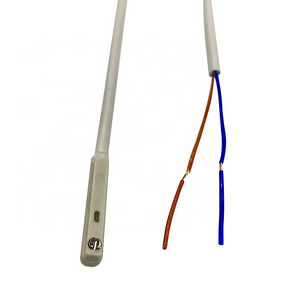

- The reed switch is very good in mobile phones, program-controlled switches, copiers, washing machines, refrigerators, cameras, disinfection cupboards, door magnets, window magnets, electromagnetic relays, electronic scales, liquid level gauges, gas meters, water meters, etc. application.

- Extreme care must be taken when cutting or bending the lead legs of the reed switch to avoid undue stress and damage to the glass-to-metal seal. Proper clamping tools must be used.

- Temperature and excessive exposure time can cause damage to the glass-to-metal seal (cracking, leakage, etc.), so fast and reliable welding techniques (processes) must be used. The recommended welding conditions are: 280-300 °C for hand welding and 250 to 300 °C for wave soldering.

Website:

http://www.smart-bes.com

Alibaba:

http://smartbes.en.alibaba.com