The Grit Size is aligned with global standard, an reference could be find in right table.

- Product Details

- {{item.text}}

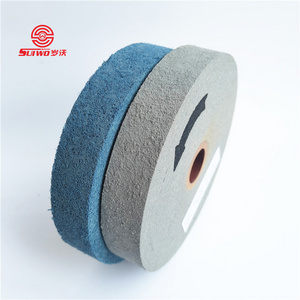

Quick Details

-

Model Number:

-

LD6S FIN 6X1X1

-

Grade/Grit:

-

FIN

-

Density:

-

6S

-

O.D.:

-

8inch,152mm

-

I.D.:

-

3inch, 25.4mm

-

Thickness:

-

1inch, 25.4mm

-

Color:

-

Gray

Quick Details

-

Type:

-

Abrasive wheel

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

99D

-

Model Number:

-

LD6S FIN 6X1X1

-

Grade/Grit:

-

FIN

-

Density:

-

6S

-

O.D.:

-

8inch,152mm

-

I.D.:

-

3inch, 25.4mm

-

Thickness:

-

1inch, 25.4mm

-

Color:

-

Gray

Light Deburring and Polishing Convolute Abrasive Wheel (LDP)

LDP is suitable for various of precision polishing and light deburs. It is designed to provide a clean and economical system for removing fine burrs while providing a highly polished finish. Used for fine deburring, polishing and finishing because of their conformability, LDP wheels will maintain critical tolerances while still providing a fine polished finish. LDP can be used as a substitute for imported light debur wheel. The applications include grinding hydraulic valve core, mold and pressure parts grinding and polishing, aircraft parts polishing, furniture glass oblique edge polishing, etc.

LDP can 100% replace the application of Scotch Brite light deburring wheel. The applications include polishing of sport ware, surgical tools, coreless polishing, auto parts etc.

Features

1. Very Long durability;

2. Excellent thermal resistance, no smearing

3. Excellent uniform surface polishing

4. Excellent conformability to workpiece

5. Low dust to ensure healthy production

6. Excellent dynamic balance

Benefits

>Suited for a broad range of polish and light deburring application

> Use both wet and dry

>Smear-resistant and cool cutting, no contamination of workpiece

Debur and Sharpen of surgical tools

Shuttles

Sand the sharp area.

Debur of auto parts

Debur and Finish of engine cover

Grit Size

Safety Awareness

The safety performance of 99D grinding wheel is strictly tested and has clear safety operation instructions. However, it is still essential to install and use it properly and stick to the safety instruction. Each product is labeled with the

MOS: Maximum Operating Speed (below table)

. The actual operating speed can not exceed the maximum operating speed.

Moreover, Please also pay attention to the mechanical protection, wear the mask, safety glass and safety shoe. Pay attention to the ventilation of the workshop.

When operating convolute wheel, we should pay special attention to the arrowhead marked on the product, and the direction of the arrow is the rotation direction of the product. The product must be operated with the right direction.

Factors to be considered before choosing

The composition, shape and material type and its hardness of the workpiece.

The roughness and surface state before the working procedure

The surface conditioning effect that the workpiece needs to be achieved, the component tolerance requirements

Tools, speed of equipment, installation size of equipment and other parameters

Grinding steps needed for processing work pieces successively

Product Choose...

Usually, we need to consider the structure of the parts, the size of the grinding wheel, and the speed of the tool and other fixed circumstances.

The SP series product is a kind of laminate structure, the edge surface is the cutting face, the cutting is relatively higher than convolute wheel, it has no rotation direction.

Convolute wheel series (LDP, DEXL, RF, LP...) is the winding structure, the inner hole size is generally 1, 3, 5, 8 inches, plane surface is the cutting surface. When it is used, it is directional and can only rotate in one direction. The arrow identifies the direction of rotation. The convolute wheel is more durable than the SP wheel, which is more suitable for sharp and harsh applications such as deburring.

Product to replace

Replacing similar products: SP series can replace various kinds of unitized wheel, fiber polishing wheel and cloth wheel with mineral; LDP, DEXL, RF, LP can replace the imported brands convolute wheels with similar application purpose.

Cross product substitution: replace steel wool, steel wire brush, abrasive, hard bristle, manual file, polishing paste, grinding fluid, grinding wheel, rubber scraper, manual sandblasting equipment, dressing, cleaning cloth etc.