GOOD QUALITY

Strong toughness, uniform particle size impact resistant, not easy to break

|

Product

|

|

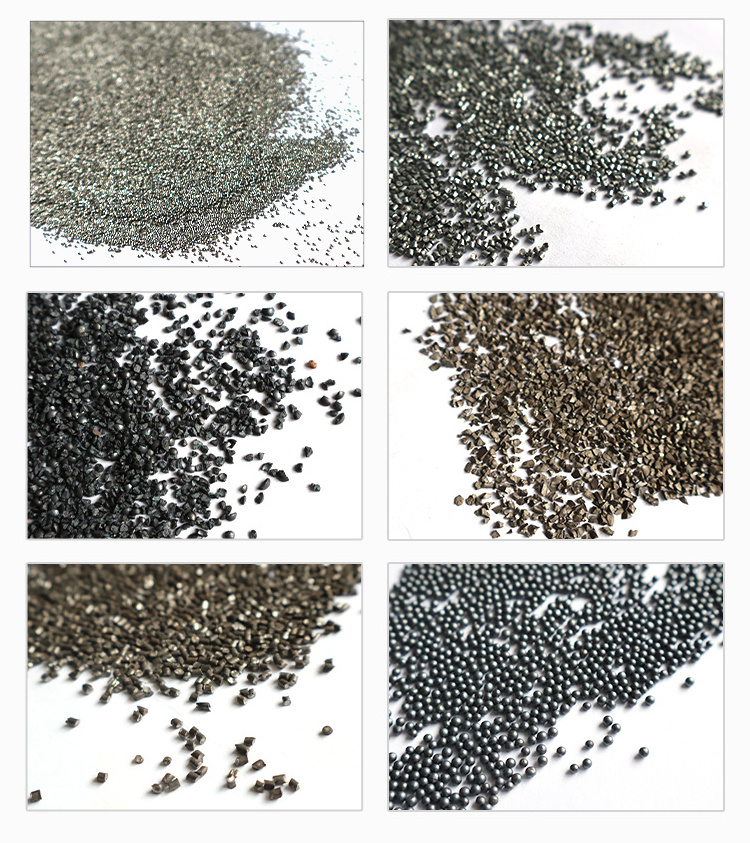

STEEL GRIT

STEEL SHOT

|

Type No.

|

STEEL GRIT GH/GL/GP10-120

STEEL SHOT S070-S1110

|

|||

|

Test Items

|

|

Specifications

|

|

|

|||

|

|

|

STEEL GRIT

|

|

STEEL SHOT

|

|||

|

Chemical Composition

%

|

C

|

0.85-1.20

|

|

0.85-1.20

|

|||

|

|

Mn

|

0.40-1.20

|

|

0.40-1.20

|

|||

|

|

Si

|

0.40-1.20

|

|

0.40-1.20

|

|||

|

|

S

|

≤0.05

|

|

≤0.05

|

|||

|

|

P

|

≤0.05

|

|

≤0.05

|

|||

|

Hardness (HRC)

|

|

60-66(GH)

50-60(GL)

42-50(GP)

|

|

40-50

|

|||

|

Metallographic Structure

|

|

Even tempered martensite

|

|

Even tempered martensite

|

|||