- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Beijing, China

-

Brand Name:

-

zander.welding.industry

-

Model Number:

-

ER316L stainless steel

-

Application:

-

for ultra-low carbon stainless steel.

-

MIG diameter:

-

0.8mm 0.9mm 1.0mm 1.2mm 1.6mm

-

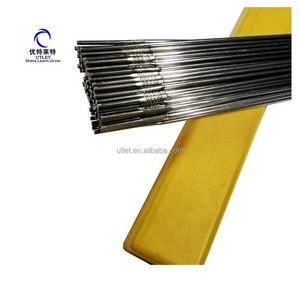

TIG diameter:

-

1.6mm 2.0mm 2.4mm 3.0mm 3.2mm 4.0mm

-

Raw material:

-

stainless steel alloy

-

Packing 1:

-

D100-1kg

-

Packing 2:

-

D200-5kg

-

Packing 3:

-

D300-15kg

-

S-k-y-p-e:

-

zander.welding.industry

-

MOQ:

-

100 kgs

-

Delivery:

-

5-7 days

-

Product Keywords:

-

Stainless steel filler wire and filler rod ER308L ER308LSi ER308

Quick Details

-

Melting Point:

-

2400

-

Weight:

-

1kg,5kg,15kg

-

Flux Content:

-

no

-

Place of Origin:

-

Beijing, China

-

Brand Name:

-

zander.welding.industry

-

Model Number:

-

ER316L stainless steel

-

Application:

-

for ultra-low carbon stainless steel.

-

MIG diameter:

-

0.8mm 0.9mm 1.0mm 1.2mm 1.6mm

-

TIG diameter:

-

1.6mm 2.0mm 2.4mm 3.0mm 3.2mm 4.0mm

-

Raw material:

-

stainless steel alloy

-

Packing 1:

-

D100-1kg

-

Packing 2:

-

D200-5kg

-

Packing 3:

-

D300-15kg

-

S-k-y-p-e:

-

zander.welding.industry

-

MOQ:

-

100 kgs

-

Delivery:

-

5-7 days

-

Product Keywords:

-

Stainless steel filler wire and filler rod ER308L ER308LSi ER308

Chemical Composition of Wire(%)

|

|

C |

Mn |

Si |

S |

P |

Cu |

Others |

|

Standard(GB) |

0.06-0.15 |

1.40-1.85 |

0.80-1.15 |

≤0.035 |

≤0.025 |

≤0.50 |

≤0.50 |

|

Standard |

0.06- 0.14 |

1.30-1.60 |

0.70-1.0 |

≤0.035 |

≤0.025 |

≤0.35 |

≤0.50 |

|

Type |

0.08 |

1.51 |

0. 80 |

0.0 15 |

0.016 |

0.20 |

0.02 |

Mechanical Proper ties of Deposited Metal

|

Tensile strength(MPa) |

Yield Point(MPa) |

Elongationδ5(%) |

Impact V-Notch (J)(-20oC) |

Shielding Gas |

|

≥500 |

≥420 |

≥22 |

≥27 |

100%CO2 |

|

560 |

500 |

27 |

102 |

100%CO2 |

Specification & Recommended Current Range(DC+)

|

Diameter(mm) |

dia 0.8 |

dia 1.0 |

dia 1.2 |

dia 1.6 |

|

F Current(A) |

40~180 |

50~220 |

80~350 |

170~550 |

|

V Current(A) |

40~140 |

50~160 |

50~180 |

50~180 |

|

OH Current(A) |

40~120 |

50~160 |

45~180 |

4 0 ~180 |

1. It has excellent mechanical performance such as fast melting rate, high depositing efficiency, stable arc, little spatter, beautiful seam.

2. The slag is fluid and when hardened it is compact and easy to remove

3. Welding of carbon steel, low alloy steel&500Mpa grade low alloy high intensity steel structures etc.

Such as vehicle, building, bridge, ship building, pressure vessel industry and pipeline etc.

4. It is suitable for all position welding of steel sheets and irregular joints even under unfavorable conditions.

5. High-speed welding of light gauge plate and pipe line steel.