- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

DFO

-

Model Number:

-

DFO-Z538

-

Surface Treatment:

-

Covered, concave, smooth, grit

-

Material:

-

Fiberglass , Resin

-

Thickness:

-

12.6-63mm

-

Certificate:

-

ISO9001

-

Resin System:

-

Iso resin,Orth resin,VE

-

Surface:

-

Covered, concave, smooth, grit

-

Advantages:

-

High strength, fire resistant, uv

Quick Details

-

Application:

-

Construction,Stair treads, walkway,

-

Technique:

-

Pultruded and Molded

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

DFO

-

Model Number:

-

DFO-Z538

-

Surface Treatment:

-

Covered, concave, smooth, grit

-

Material:

-

Fiberglass , Resin

-

Thickness:

-

12.6-63mm

-

Certificate:

-

ISO9001

-

Resin System:

-

Iso resin,Orth resin,VE

-

Surface:

-

Covered, concave, smooth, grit

-

Advantages:

-

High strength, fire resistant, uv

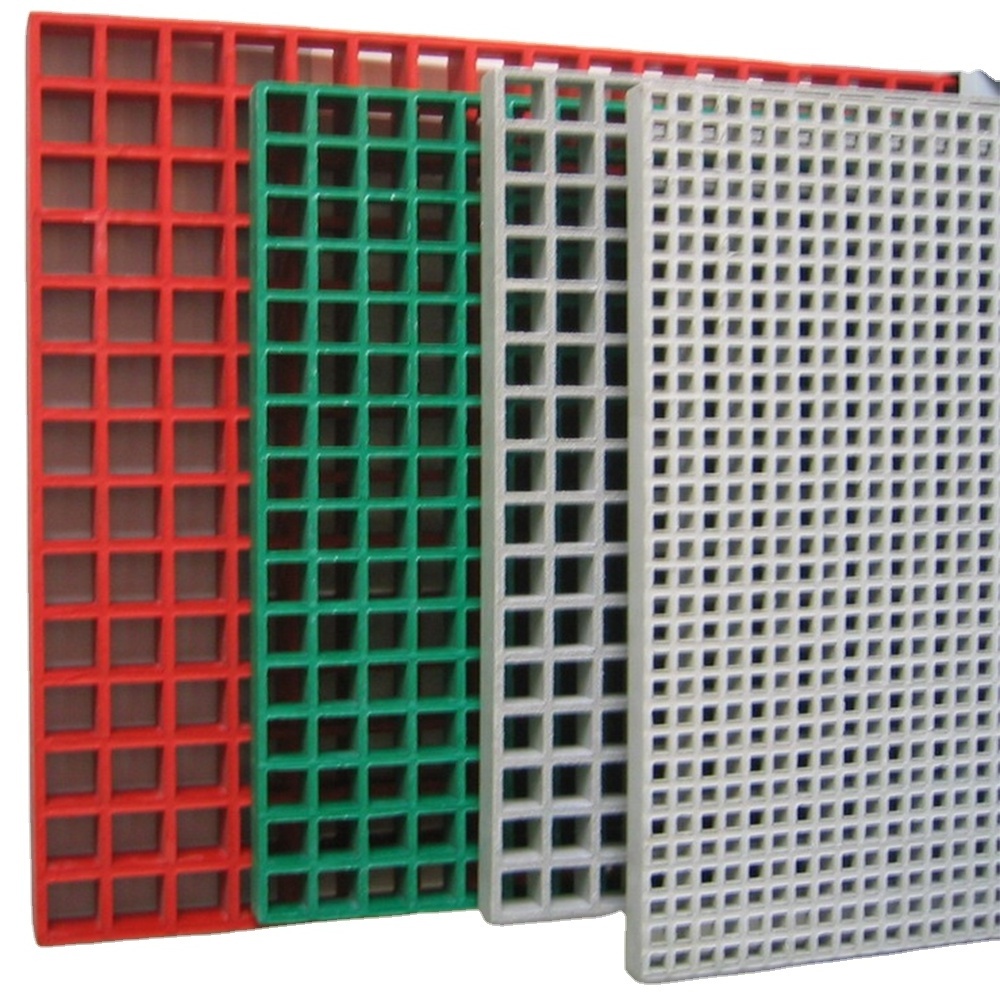

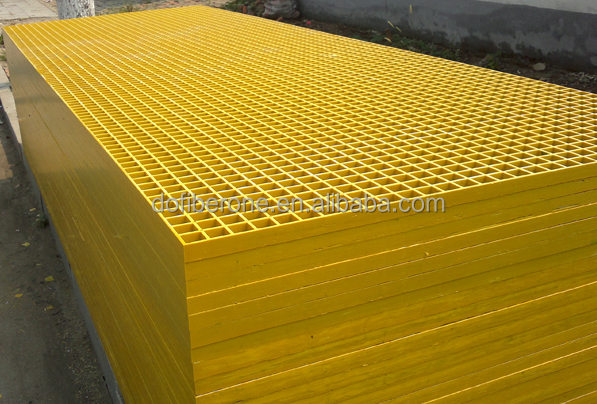

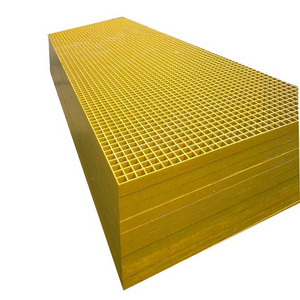

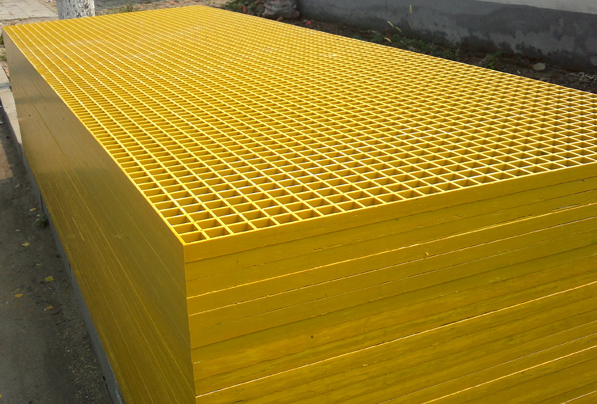

Fiberglass Plastic Grating 4x8 FRP Sheets

Product Description

1 Introduction

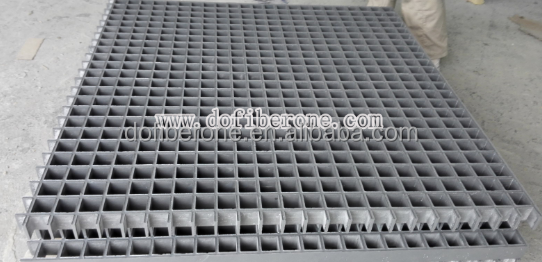

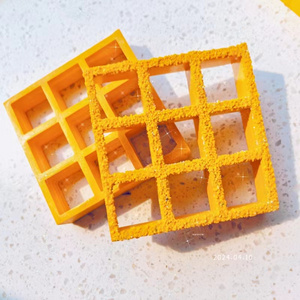

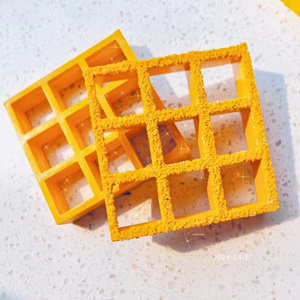

Molded grating process:

Molded grating is manufactured by laying continuous glass fibres in the mould in the direction of vertical and horizontal, and thurougly wetted out with resin, layer by layer. When the weaving process is completed, the mould is heated to cure the panel. After curing, the panel is ejected from the mould. The standard panel would have meniscus (concave) top surface. Any process such as post applied grit could be bonded after as a secondary operation. This continuous process produces an integral, one piece panel, which offers excellent corrosion resistance as well as bi-directional strength.

Pultruded grating process:

Pultrusion is a manufacturing process for producing continuous lengths of reinforced polymer structural shapes with constant cross-sections. Raw materials are a liquid resin mixture (containing resin, fillers and specialized additives) and flexible textile reinforcing fibers. The process involves pulling these raw materials (rather than pushing, as is the case in extrusion) through a heated steel forming die using a continuous pulling device.

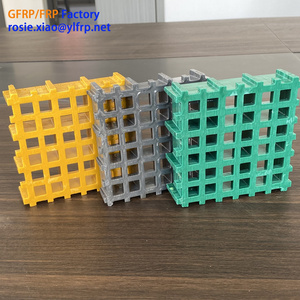

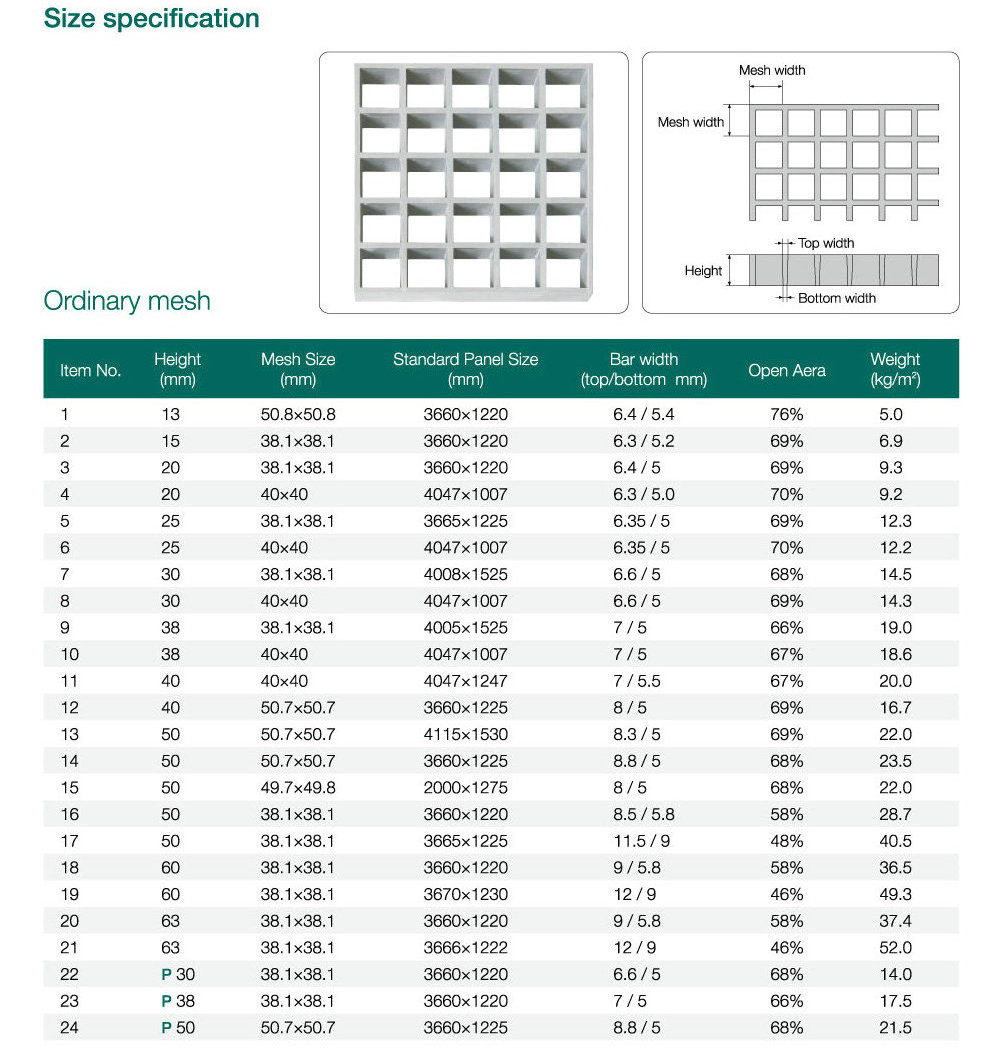

2 Specification of FRP molded grating

3 Specification of FRP pultruded grating

4 Surface

5 Advantage of fiberglass grating:

High strength

Anti-aging

Anti-fire

Anti-slip

Light but high loaded strength

Long service life and maintenance free

Non-conduction or magnetic

Easy install and

Various sizes and colors available

6 Application of fiberglass grating:

1)Anti-slippery floor, stair tread, foot bridge

2)Operation platform, trench cover

3)Off-shore oil rig, moor shipyard, shipping deck, ceiling

4)Ramp ladder, scaffold, railway footpath

5)Decorative grid, man-made fountain pool grid

More FRP products;

7 The package and loading

Overview

Specifications:

Place of rigon: Shanghai China (Mainland) Brand Name:Dofinberone

Model Number: FRP GRP Grating Application:Chemical enterprise,etc

Technique: Molde and pultruded C olor: yellow, blue, green, gray, red or customizable

Surface Treatment: concave,covered,smooth,grit Material:Fiberglass \Glassfiber\FRP\GRP+ Resin

Certificated: ISO9001, Height:15mm,25mm,30mm,38mm,etc

Panel size: 1220x3660mm,customized Mesh size:19*19mm/38*38mm/40*40mm,etc

Paking & Delivery:

Packaging Details: fiberglass grating Packed in metal pallets and customers' requirement is accepted.

Delivery Detail: 10 days

Our market