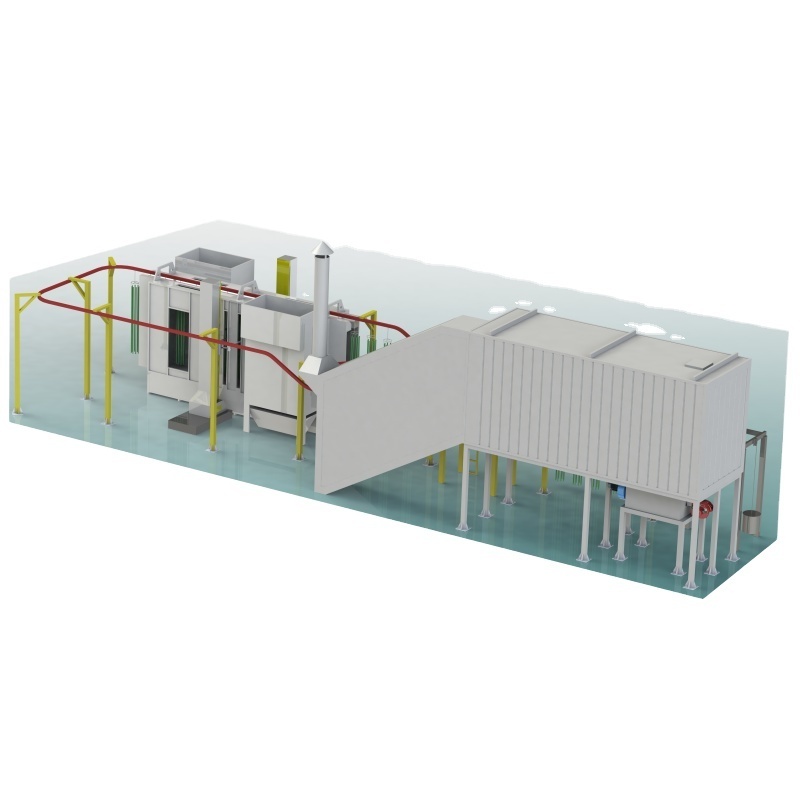

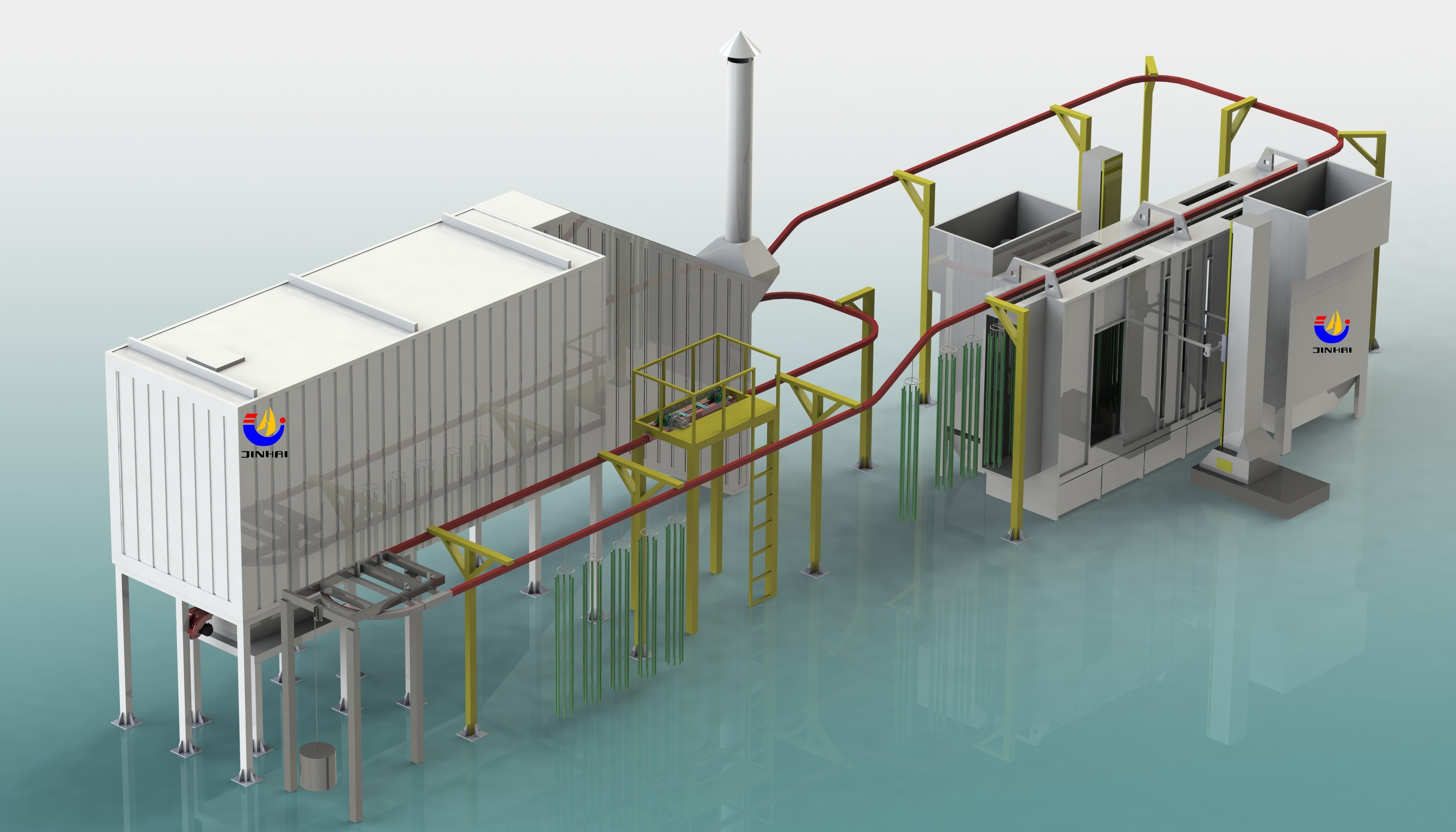

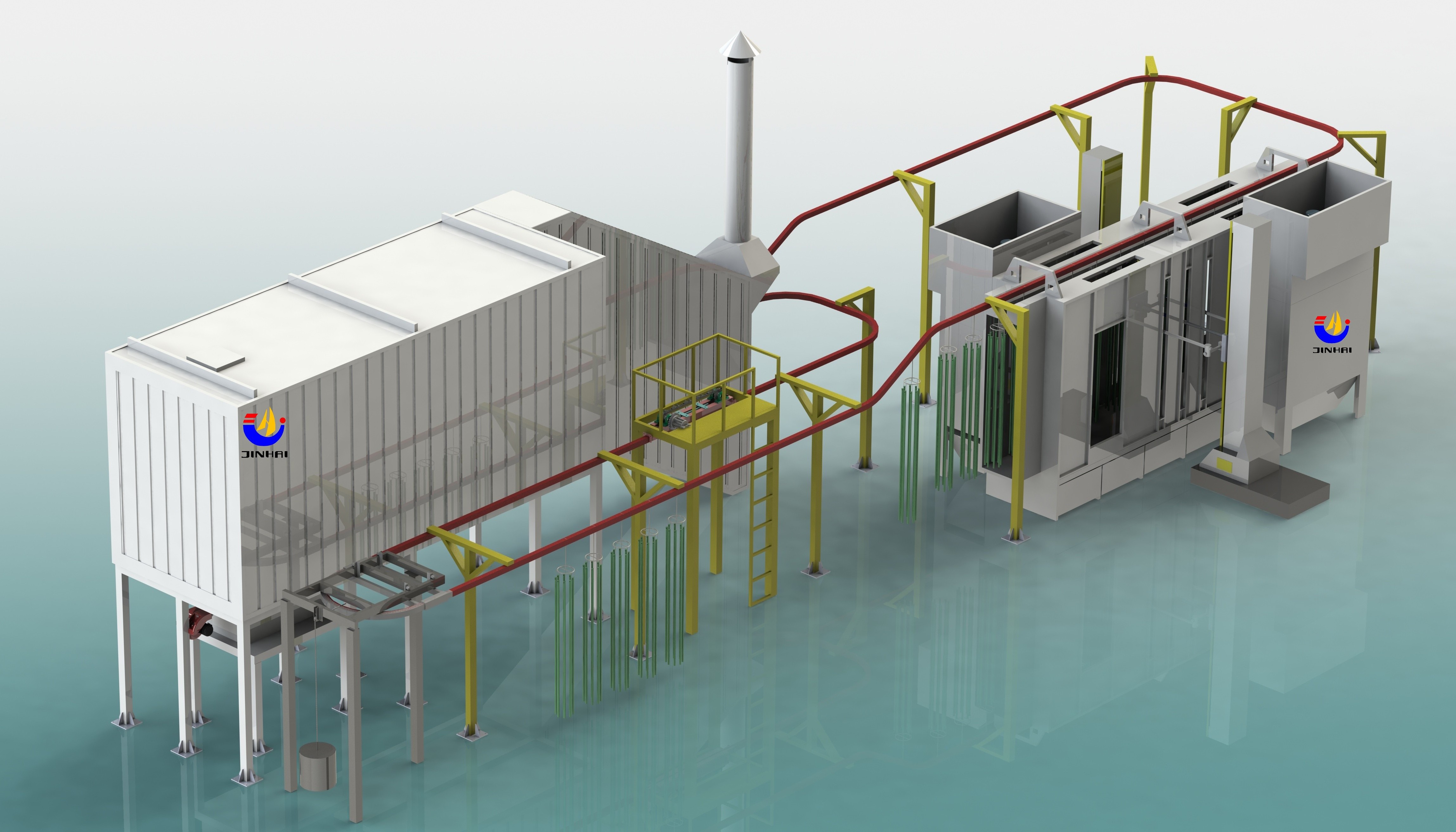

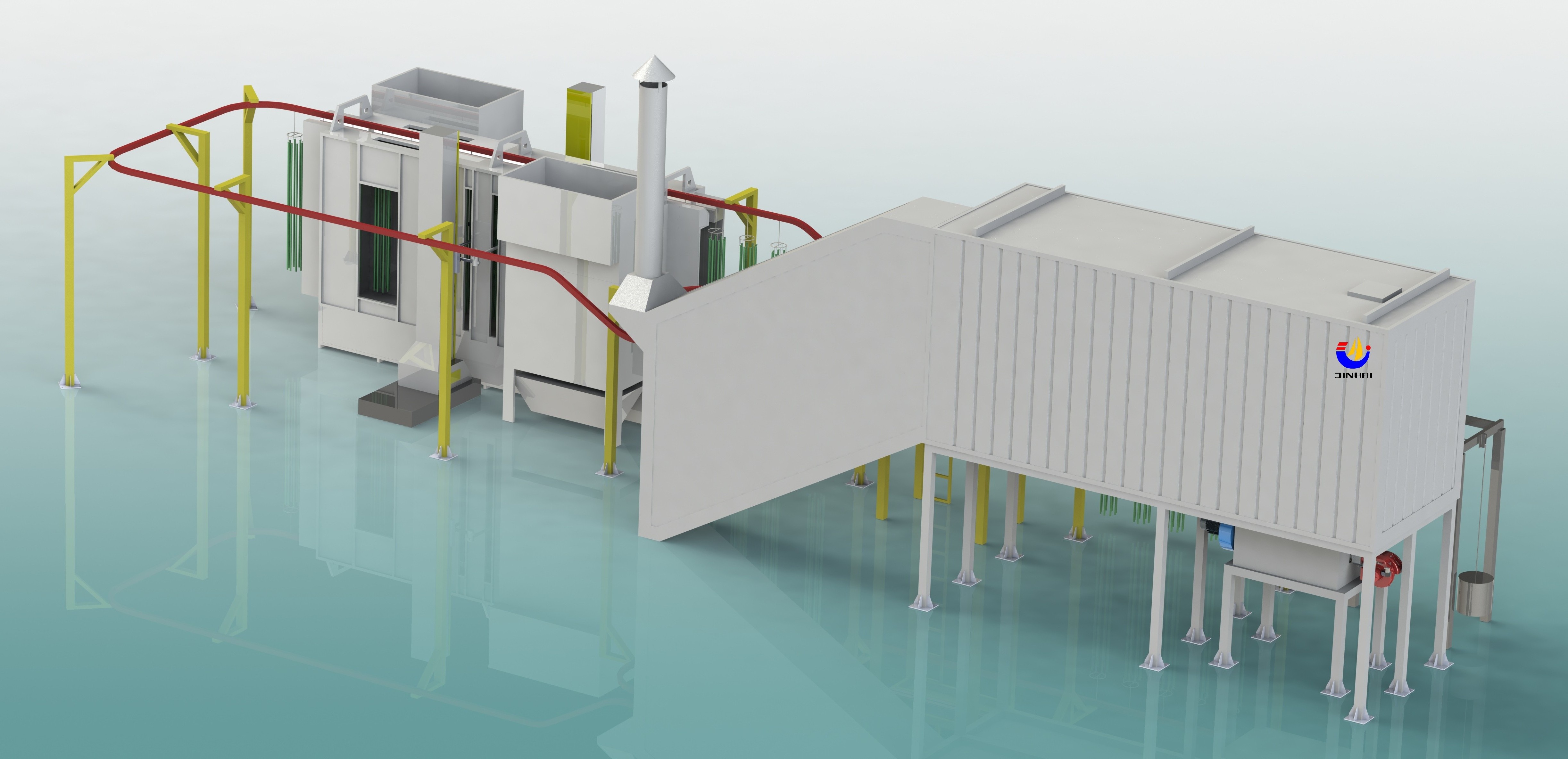

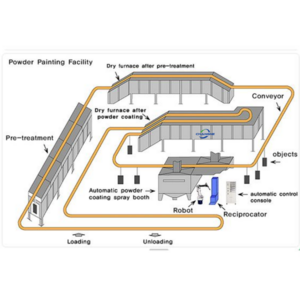

Spray method: spray sprinkler of channel for rinsing

In the full spray method, the liquid is pressurized by a pump, and it is formed into a mist with a pressure of 0.1-0.2Mpa, then sprayed on the workpieces to achieve the treatment effect.

Advantage

•Suitable for processing workpieces with simple shapes

•Useful for large-scale operation requirements

•Space saving and less equipment investment

•Strong work continuity and high efficiency