- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Saber tooth tiger

-

Voltage:

-

220/380

-

Dimension(L*W*H):

-

OEM

-

Weight (KG):

-

1300

-

Product name:

-

Bus Processing Machine

-

Application:

-

Copper Busbar Alumimum Busbar

-

Certification:

-

CE ISO9001

-

Color:

-

Red Black

-

Usage:

-

Metal Sheet Punching Cutting Bending

-

Delivery time:

-

3 Days Busbar Process Machine

-

Motor power:

-

3 X5.5 KW

-

MOQ:

-

1 Set

-

Package:

-

Wooden Cases Outside

-

Feature:

-

Automatic Operation

Quick Details

-

Max. Thickness (mm):

-

18 mm

-

Max. Width (mm):

-

260 mm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Saber tooth tiger

-

Voltage:

-

220/380

-

Dimension(L*W*H):

-

OEM

-

Weight (KG):

-

1300

-

Product name:

-

Bus Processing Machine

-

Application:

-

Copper Busbar Alumimum Busbar

-

Certification:

-

CE ISO9001

-

Color:

-

Red Black

-

Usage:

-

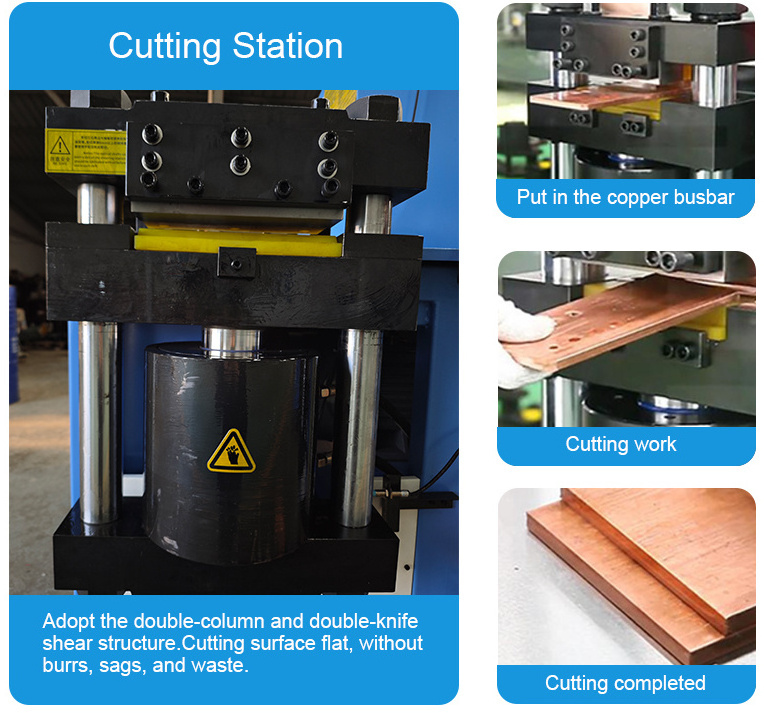

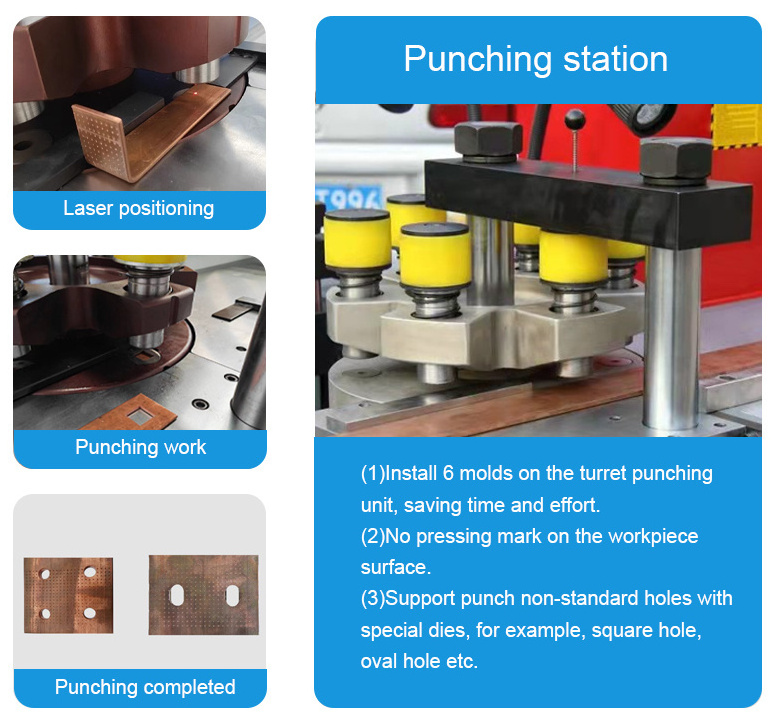

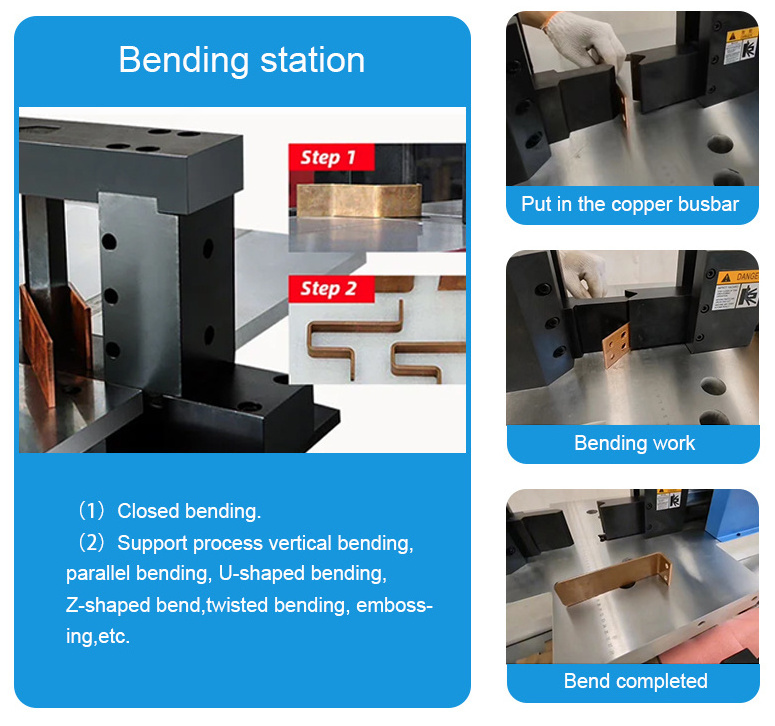

Metal Sheet Punching Cutting Bending

-

Delivery time:

-

3 Days Busbar Process Machine

-

Motor power:

-

3 X5.5 KW

-

MOQ:

-

1 Set

-

Package:

-

Wooden Cases Outside

-

Feature:

-

Automatic Operation

Products Description

ZTMX series busbar machine can respectively punching, cutting, bending copper or aluminum busbar, with high production efficiency.ZTMX-80 series busbar processing machine is mainly applicable to the manufacturing industry of high and low voltage switch cabinet and transformer.

Structural features

Product Details

1.The CNC system adopts the highest configuration Siemens system, calculating various bending angles and unfolding lengths of copper busbar to save materials for users.Store multiple sets of parameters for next use without the need for repeated editing.

2.The graduation ruler of the bending station adopts laser engraving, which will not cause damage to the bottom of the copper busbar due to friction when working.

3.Adopt Siemens PLC and Schneider Electric to ensure the safety and stability of the machine, avoiding machine fault and making it more durable.

4.The punching and shearing stations are equipped with manual positioning rulers, which can accurately position the copper busbar without the need for marking during the work process, greatly improving work efficiency and processing accuracy.

5.Equipped with automatic refueling function.Adopt three power motors are used, corresponding to the punching, shearing, and folding stations, to ensure stable power for the three stations, each performing its own duties without interfering with each other.

ZTMX-01K ZTMX-03K

(1)Motor:01K has one motor,punching, shearing, and bending can’t work at the same time;803K has three motors, and punching, shearing, and bending can work simultaneously.

(2)Efficiency: 01K is suitable for customers with smaller workloads. 803K has high efficiency and is more suitable for customers with larger workloads.

(2)Efficiency: 01K is suitable for customers with smaller workloads. 803K has high efficiency and is more suitable for customers with larger workloads.

Product Paramenters

|

Function

|

Item

|

ZTMX-301K

|

ZTMX-303K

|

ZTMX-501k

|

ZTMX-503k

|

ZTMX-801K

|

ZTMX-803K

|

|

Punching

|

Max power

(KN)

|

350

|

350

|

550

|

550

|

800

|

800

|

|

|

Punching Diameter

(mm) |

φ4.3-φ25

|

φ4.3-φ25

|

φ4.3-φ32

|

φ4.3-φ32

|

φ4.3-φ32

|

φ4.3-φ32

|

|

|

Max thickness

(mm) |

15

|

15

|

18

|

18

|

18

|

18

|

|

Shearing/cutting

|

Max thickness

(mm) |

15

|

15

|

260

|

260

|

18

|

18

|

|

|

Max width

(mm) |

160

|

160

|

260

|

260

|

300

|

300

|

|

Bending

|

Max power

(KN) |

350

|

350

|

550

|

550

|

800

|

800

|

|

|

Max width

(mm) |

160

|

160

|

260

|

260

|

300

|

300

|

|

|

Max thickness (mm)

|

15

|

15

|

18

|

18

|

18

|

18

|

|

Vertical bending

|

Max size

|

110*10

|

110*10

|

110*10

|

110*10

|

110*10

|

110*10

|

|

Power of Main Motor

|

(KW)

|

4

|

3x4(12KW)

|

5.5

|

3x5.5(16.5KW)

|

7.5

|

3x7.5(22.5KW)

|

|

Weight of machine

|

(T)

|

1.3

|

1.5

|

1.8

|

2.2

|

1.8

|

2.5

|

|

Outline Dimensions

|

(mm)

|

1800x1400x1300

|

1800x1400x1400

|

2000x1500x1400

|

2000x1500x1500

|

2200x1500x1400

|

2200x1500x1500

|

|

Size of worktable

|

One floor

|

1440mmx

1240mm

|

1440mmx

1240mm

|

1540mm x 1450mm

|

1540mm x 1450mm

|

1540mm x 1450mm

|

1540mm x 1450mm

|

|

|

Two floors

|

|

890mmx

500mm

|

|

1000mm x 500mm

|

|

1000mm x 500mm

|

Samples

Accessories

|

No.

|

Item

|

Quantity

|

|

|

|

1

|

Punching die

|

8 sets

|

Round hole:7/9/11/13/17/21

|

|

|

|

|

|

Oval hole:11×15/13×18

|

|

|

2

|

Horizontal bending die

|

2 sets

|

(R5/R10)

|

|

|

3

|

Vertical bending die

|

1 set

|

|

|

|

4

|

Die pins

|

2 pieces

|

|

|

|

5

|

Equipment manual

|

1 set

|

|

|

|

6

|

Foot switch

|

3 pairs

|

|

|

|

7

|

U-bending die

|

1 piece

|

|

|

|

8

|

Spare proximity switch

|

1 piece

|

|

|

|

9

|

Equipment common tool

|

1 set

|

|

|

|

10

|

Punching laser positioning light

|

1 piece

|

|

|

|

11

|

Punching positioning needle

|

1 piece

|

|

|

|

12

|

Embossing die

|

1 set

|

|

|

|

13

|

Spare sealing ring

|

1 piece

|

|

|

|

14

|

Level the ground angle

|

4 pieces

|

|

|

|

15

|

Cutting blade

|

1 pc (Installed on machine)

|

|

|

|

16

|

Small bending mold

|

1 set(R3)

|

|

|

Product packaging

Why Choose Us

Hot Searches